Combined type maize decortication and milling machine

A combined type of peeling machine technology, which is applied in grain husking, grain degerming, grain processing, etc. It can solve problems such as stuffy cars, high power consumption, and material blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

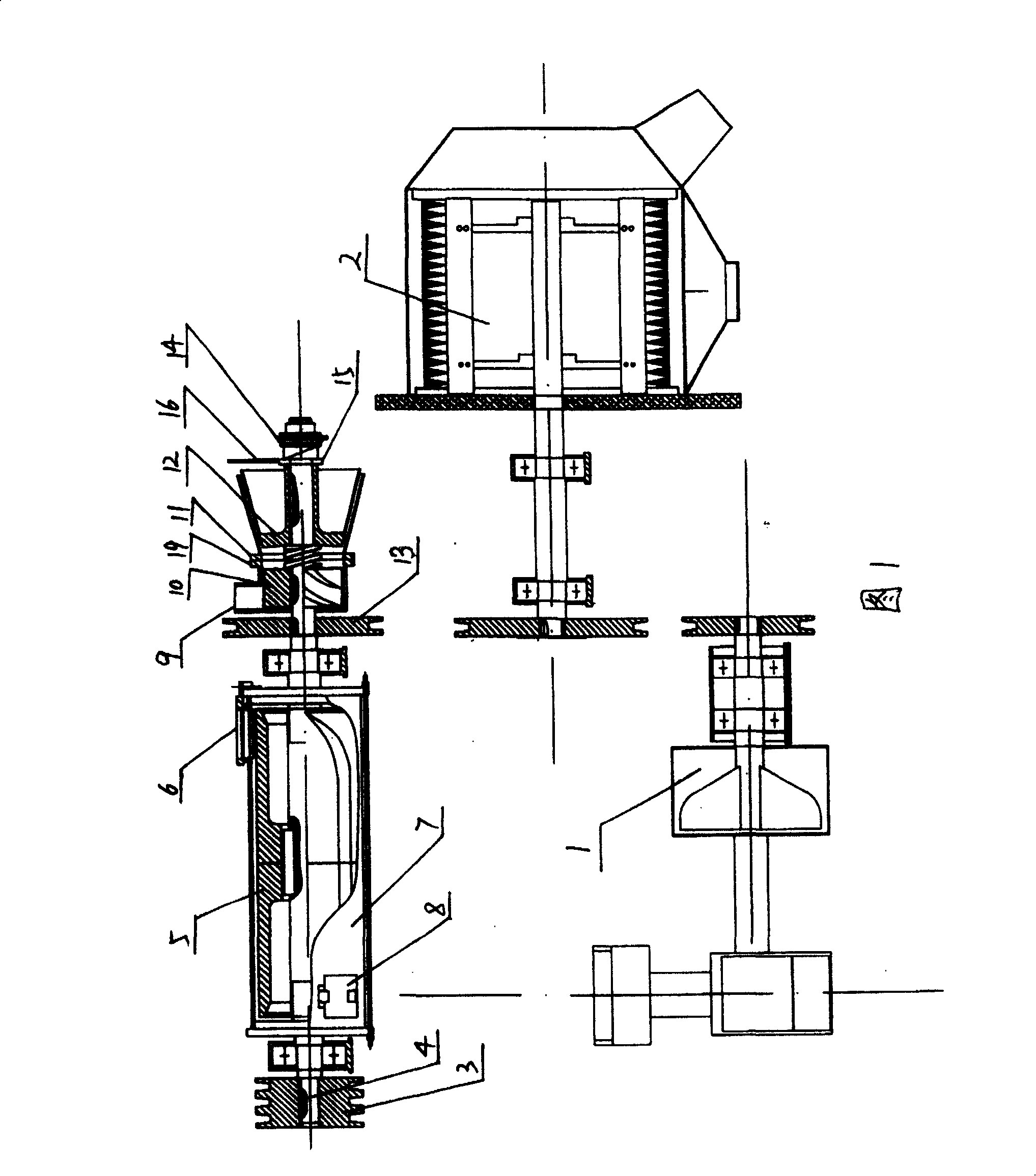

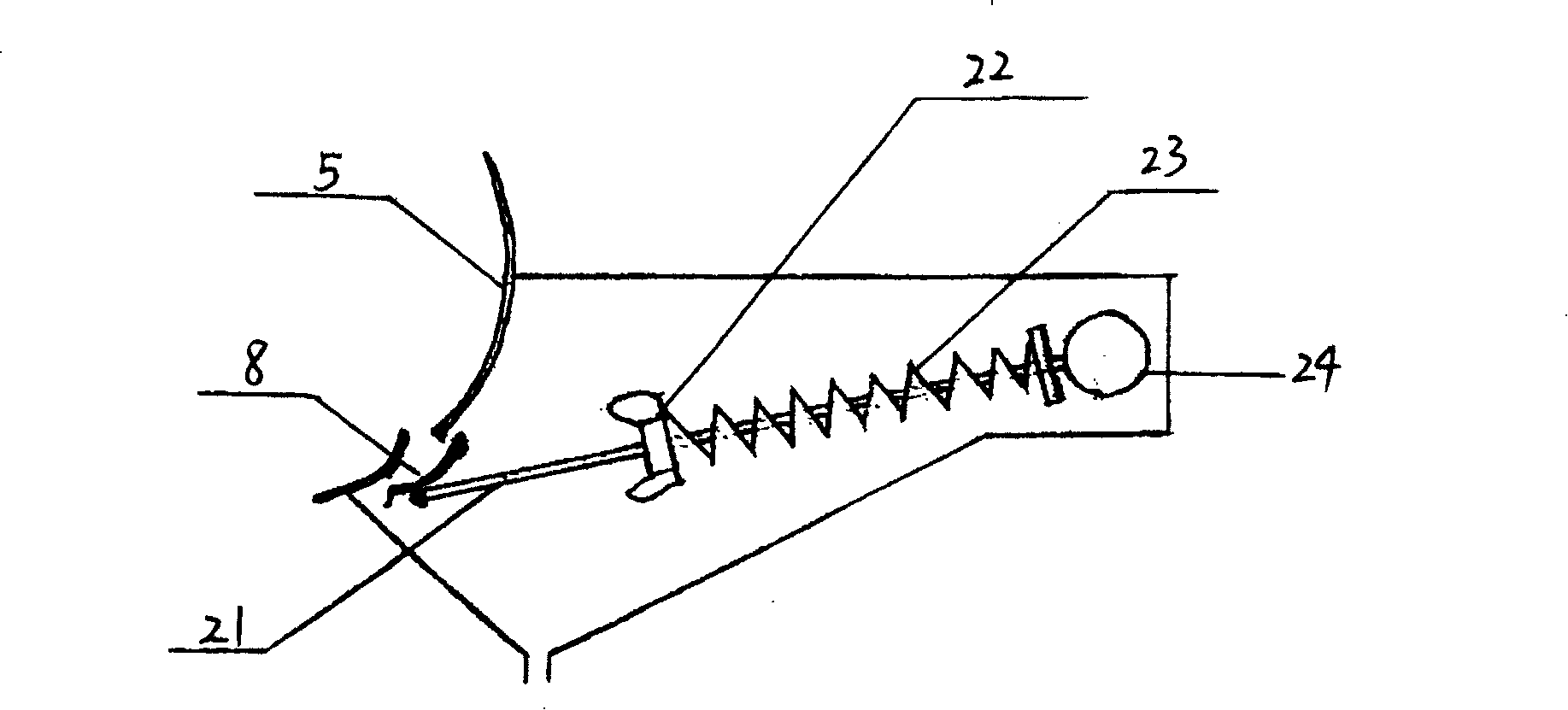

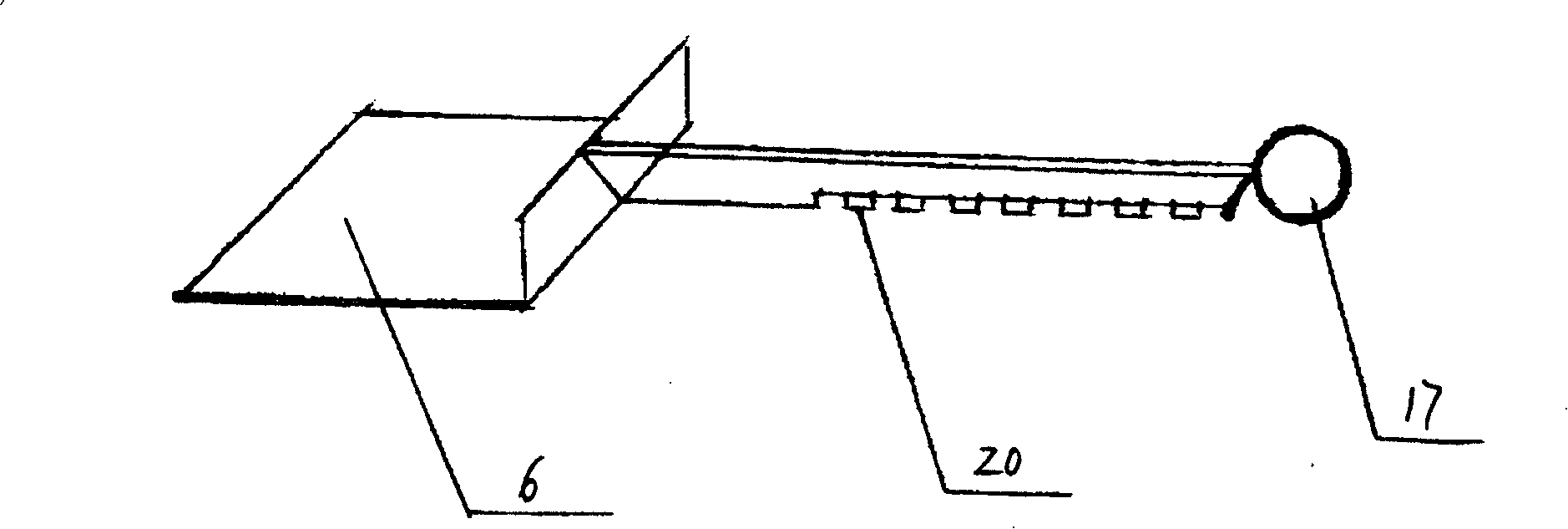

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes four parts: a peeling machine, a grits making machine, a fan 1, and a classifier 2. The peeling machine includes a driving wheel 3, a main shaft 4, a roller 5, a feed port 6, a drum-shaped screen 7, an outlet Feed port 8, the grits making machine includes feeding chamber 9, propeller 10, static grinding head 11, moving grinding head 12, driven wheel 13, peeling machine, grits making machine share a main shaft 4, static grinding head 11 tail is installed with A special steel plate fixing seat 19 for fixing the static grinding head; a clutch 14 is fixed on the main shaft at the end of the grits making machine, and one side of the clutch 14 is a clutch bearing 15 and a clutch claw lever 16; The feed handle 17 at position 20; the discharge automatic adjustment device 18 is installed at the discharge 8 place, and the discharge automatic adjustment device 18 includes a scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com