Fault diagnosis apparatus and method for hot fine rolling band steel

A technology for fault diagnosis and hot finishing, which is used in metal processing equipment, metal rolling, metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

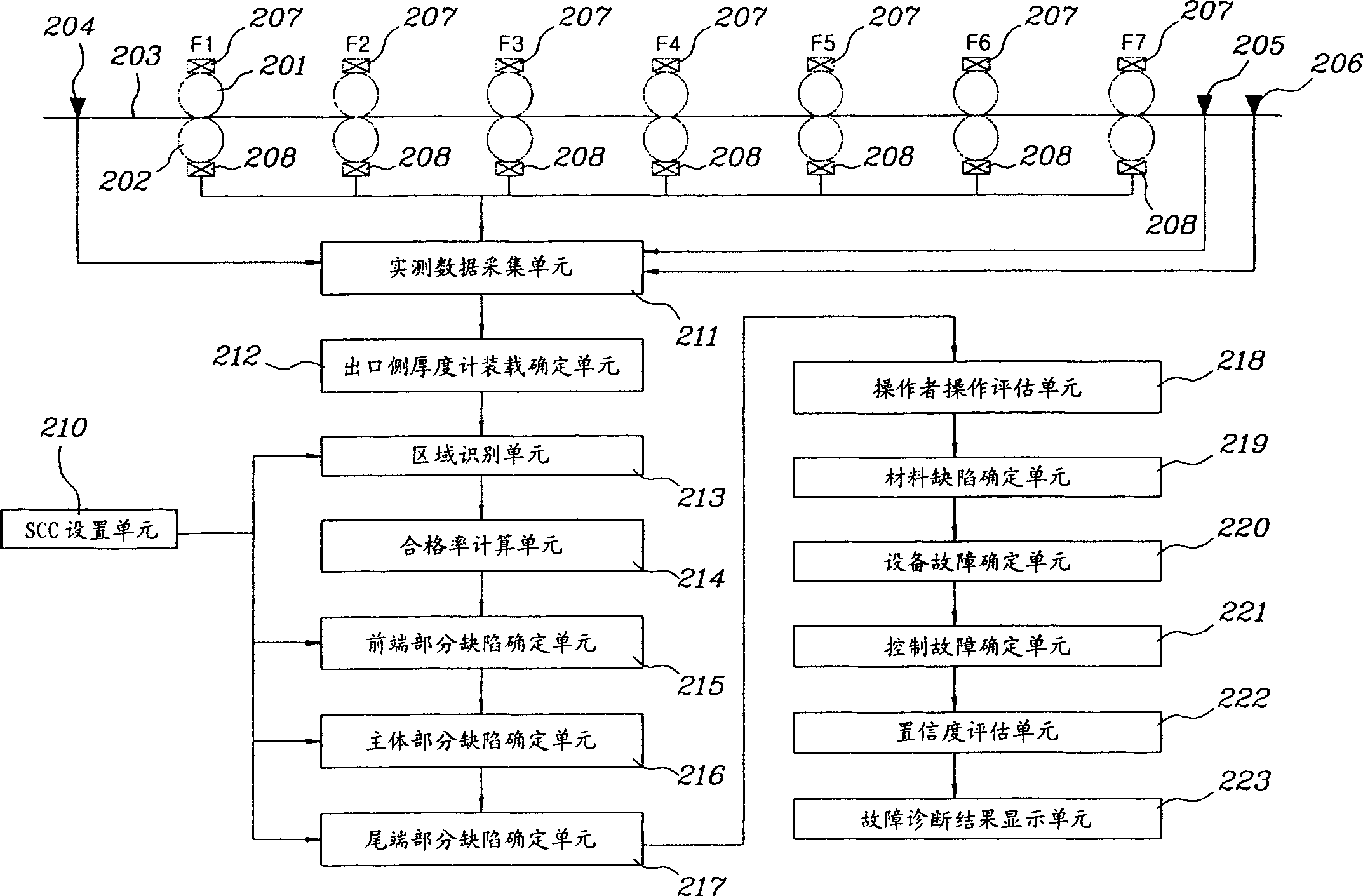

[0036] The drawings are described below, wherein the same or similar components are denoted by the same reference numerals in different drawings.

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

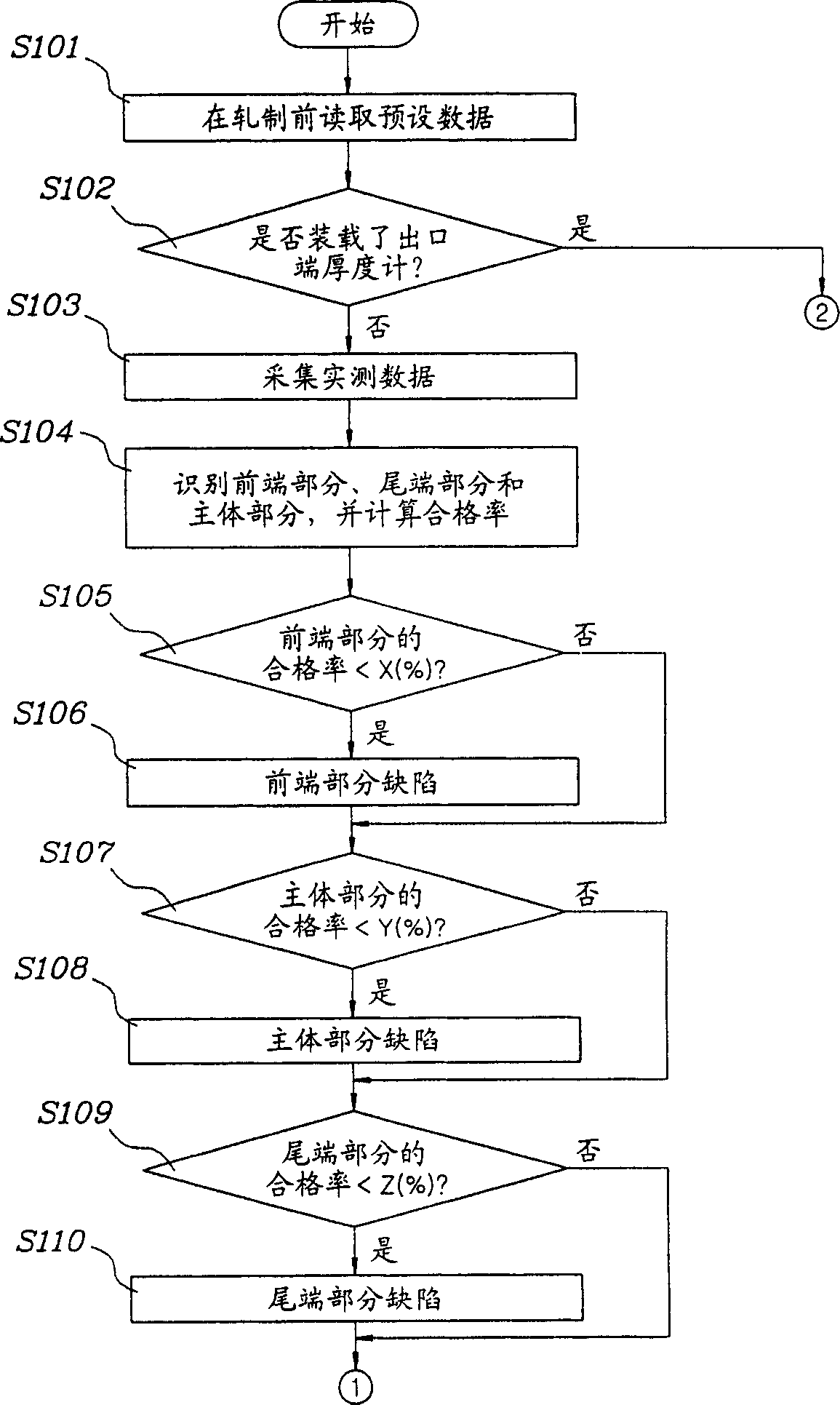

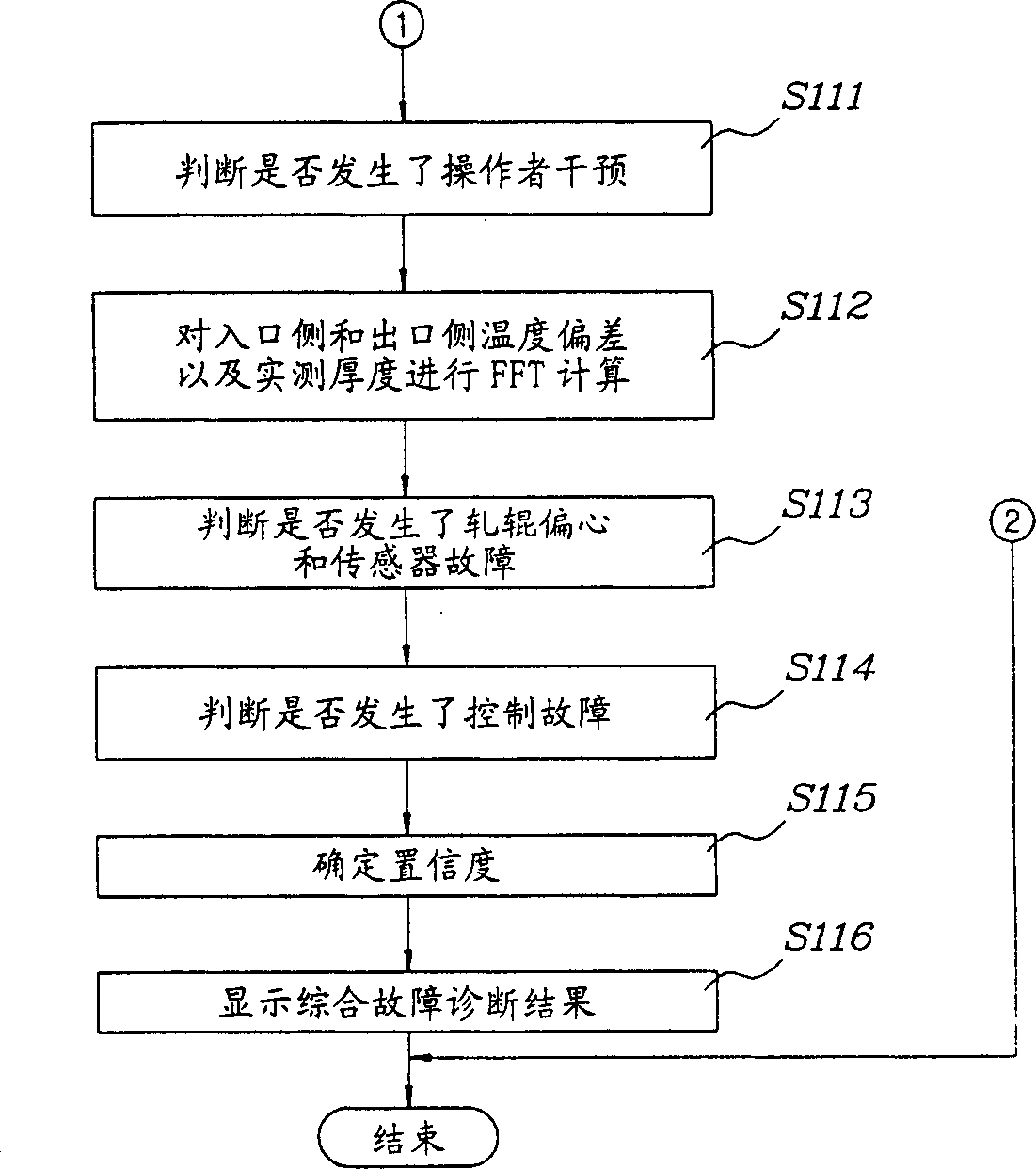

[0038] Figure 1a , Figure 1b and figure 2 Shown is a flow chart of a method for diagnosing a fault in hot finish rolling of a strip according to a preferred embodiment of the present invention, which will be described in detail below.

[0039] refer to Figure 1a and 1b , the hot finish rolling fault diagnosis method of the strip proposed by the present invention includes the following algorithms.

[0040] In step S101, after reading the values set according to the rolling conditions such as target thickness, target load, roll speed and roll gap from the monitoring computer (SCC) setting unit 210, it is determined whether the The thickness signal of the rolled plate 203 is applied by the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com