Inspection jig for radio frequency device ,and contact probe imcorporated in the jig

A fixture and probe technology, applied in the field of contact probes, can solve the problems of low durability, high cost and poor reliability of contact probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

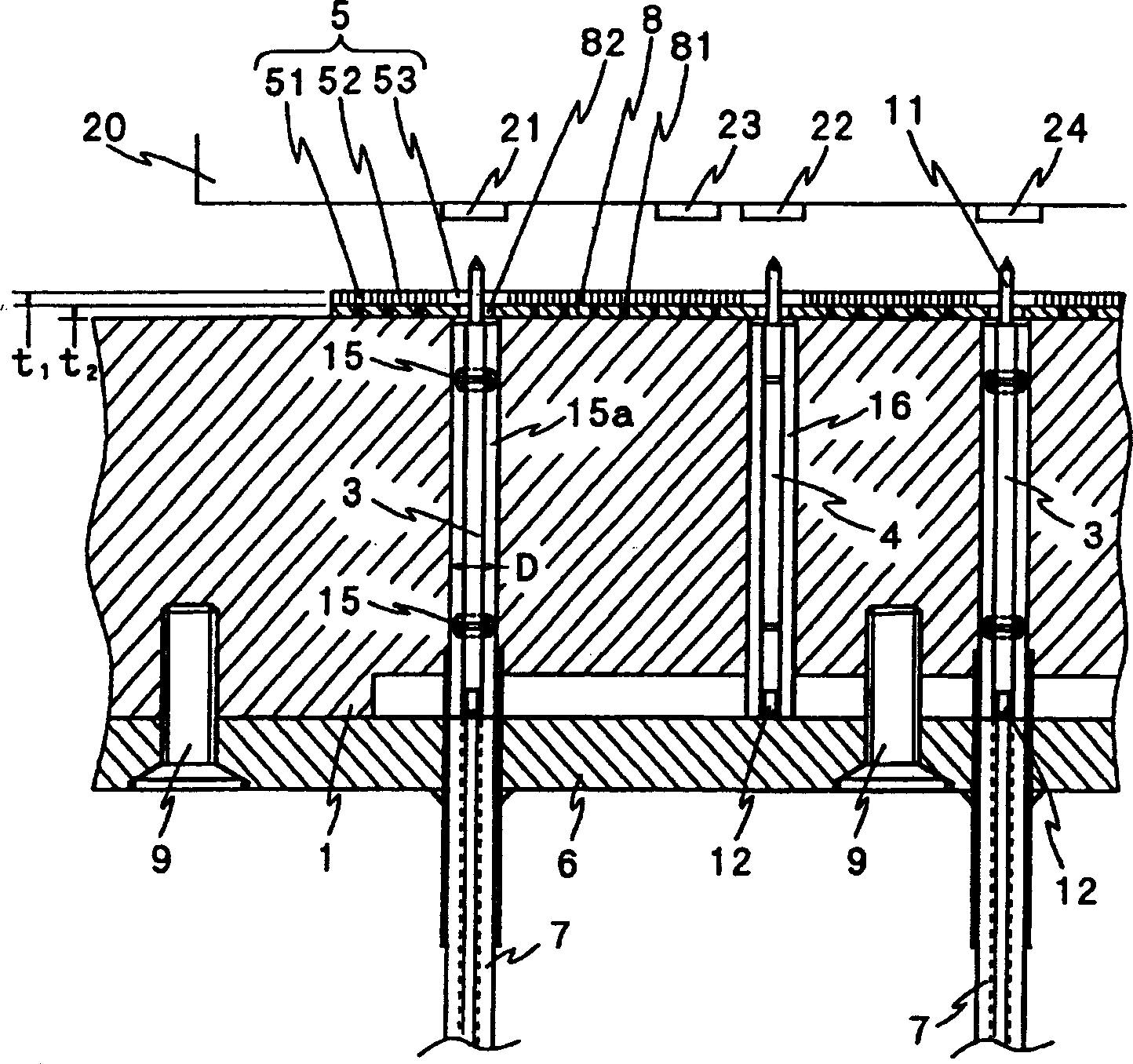

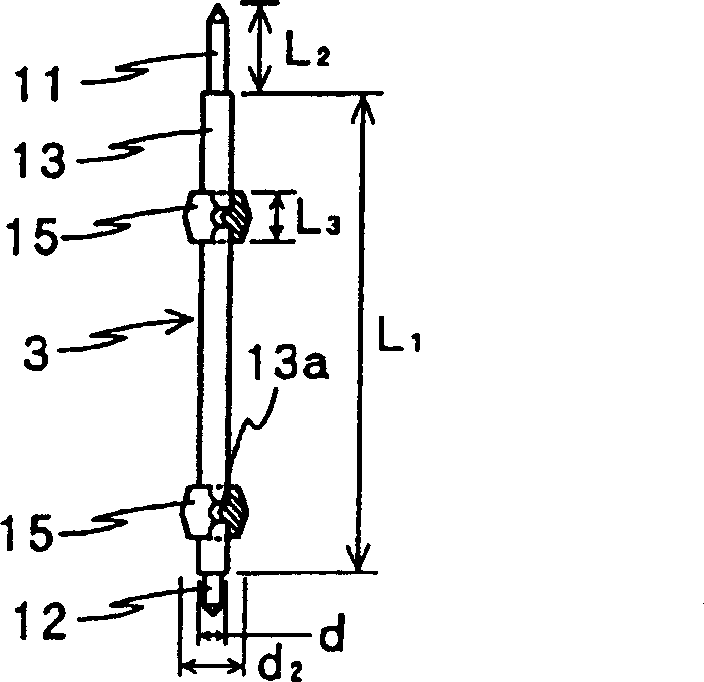

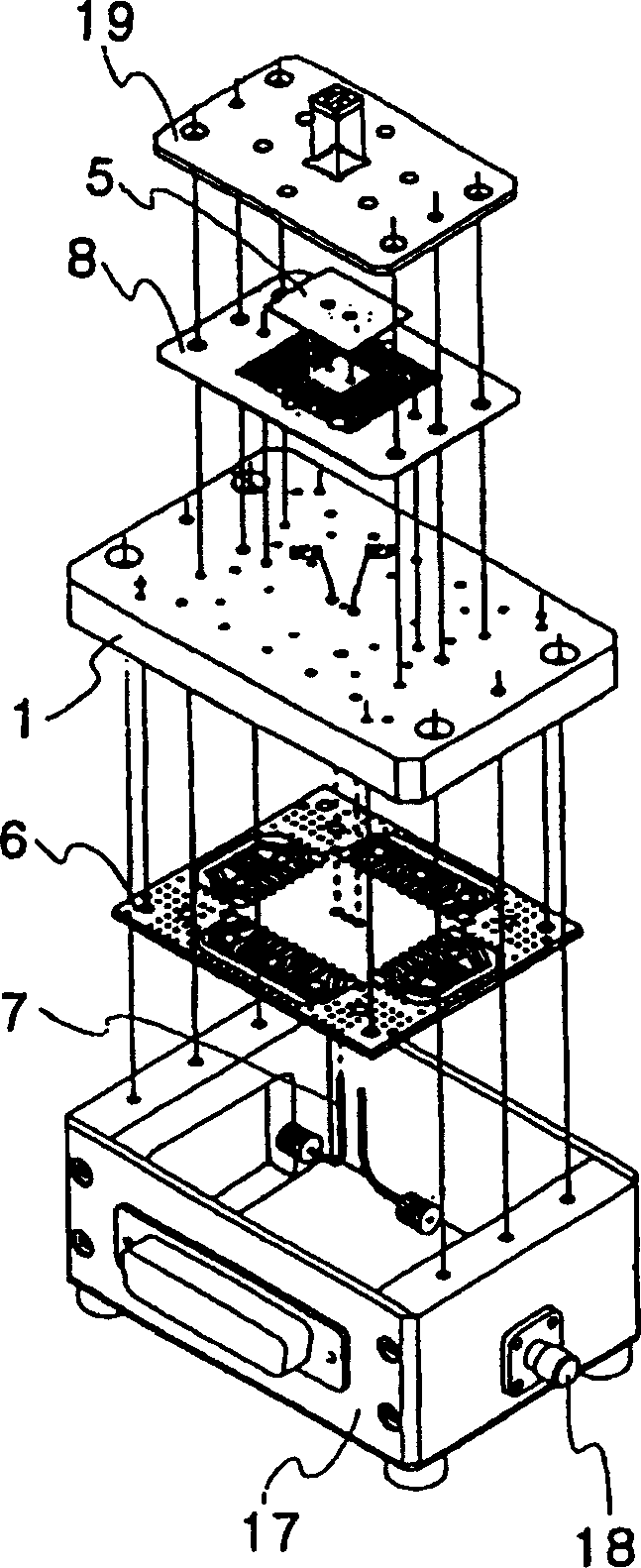

[0039] As shown in FIG. 1 , in the RF device inspection jig according to one embodiment of the present invention, an RF signal contact probe 3 is set in the metal block 1 , so that the tip of the retractable striker 11 protrudes from one side of the metal block 1 . The device under test 20 on which the RF circuit is formed is pressed against the metal block 1 so that the RF signal terminal 21 and the device under test terminal 24 are brought into contact with the contact probe 3 . By testing the test circuit in which the coaxial cable 7 is connected to the other end of the contact probe 3, the electrical test of the device 20 under test is performed.

[0040]In this embodiment, the dielectric ring 15 is fixed at least two places on the periphery of the contact probe 3 and fitted into the through hole of the metal block 1 to form a hollow portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com