Inspecting method and storage medium for storing program of the method

a technology of probe apparatus and program, which is applied in the direction of individual semiconductor device testing, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of large temperature difference between the target object and the probe, damage to the probe or the target object, and the reliability of inspection may deteriorate, so as to achieve the effect of increasing the operating rate of the probe apparatus and high reliability of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

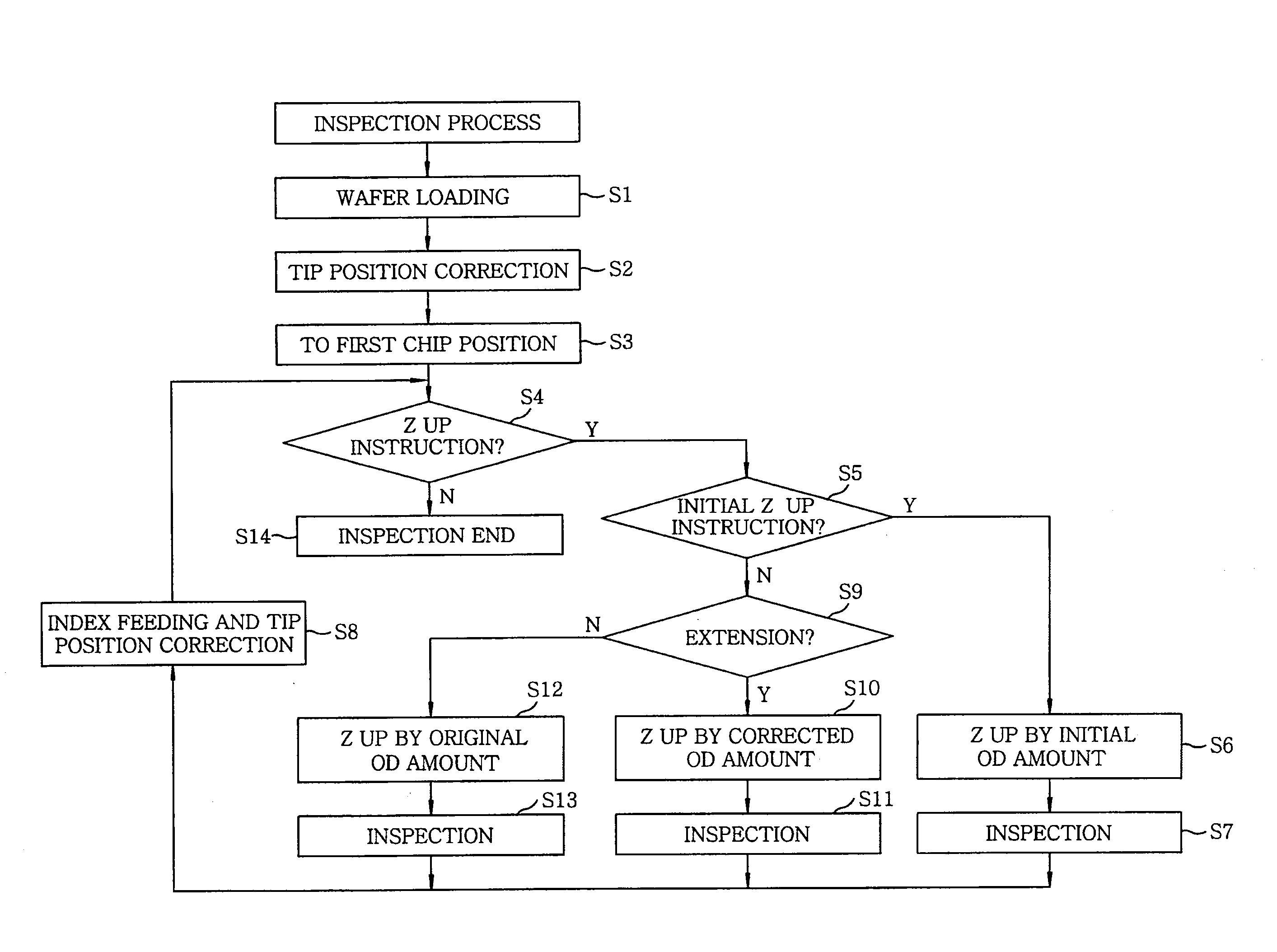

[0032]Embodiments of the present invention will be described with reference to FIGS. 1 to 5 which form a part hereof.

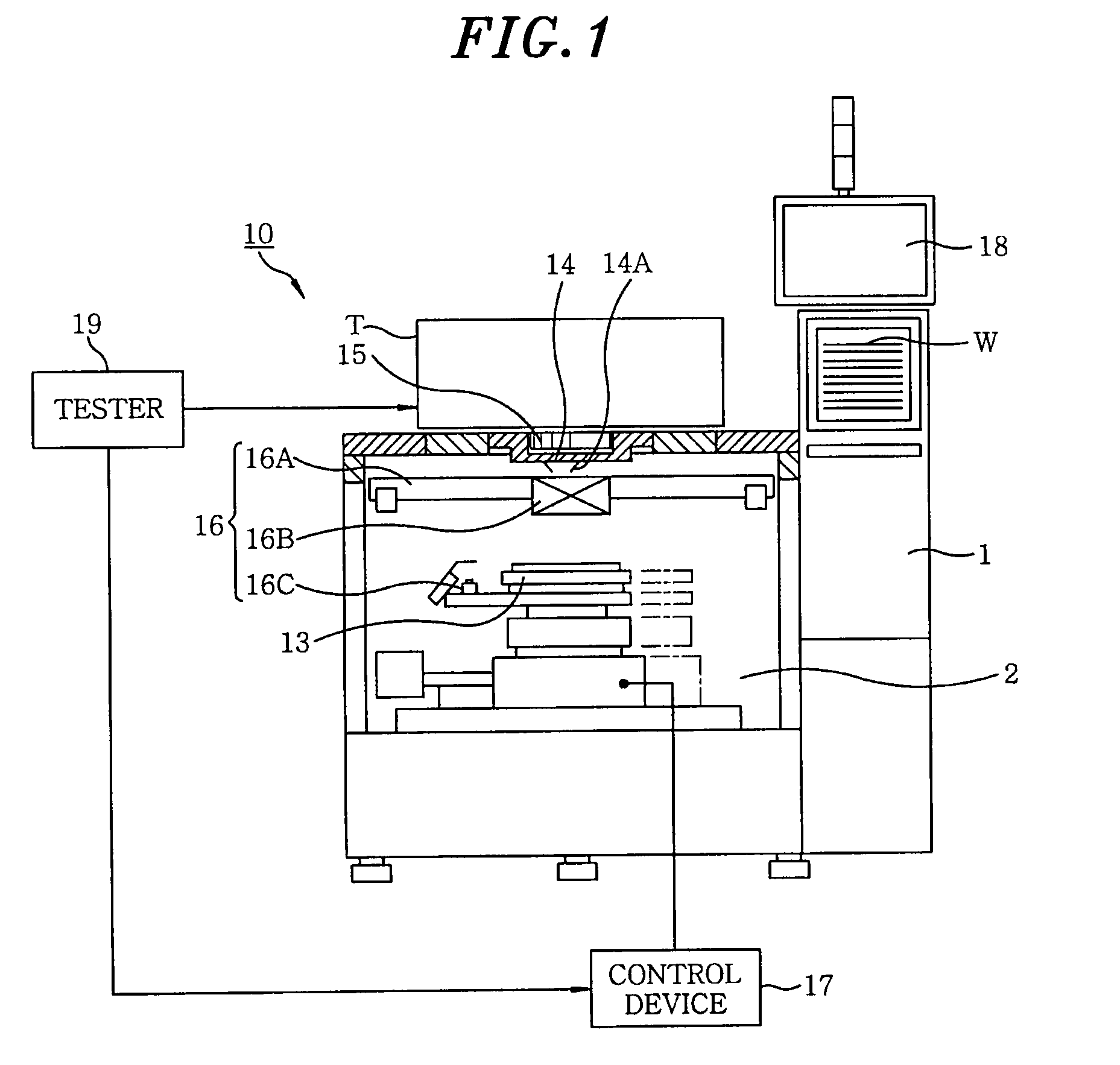

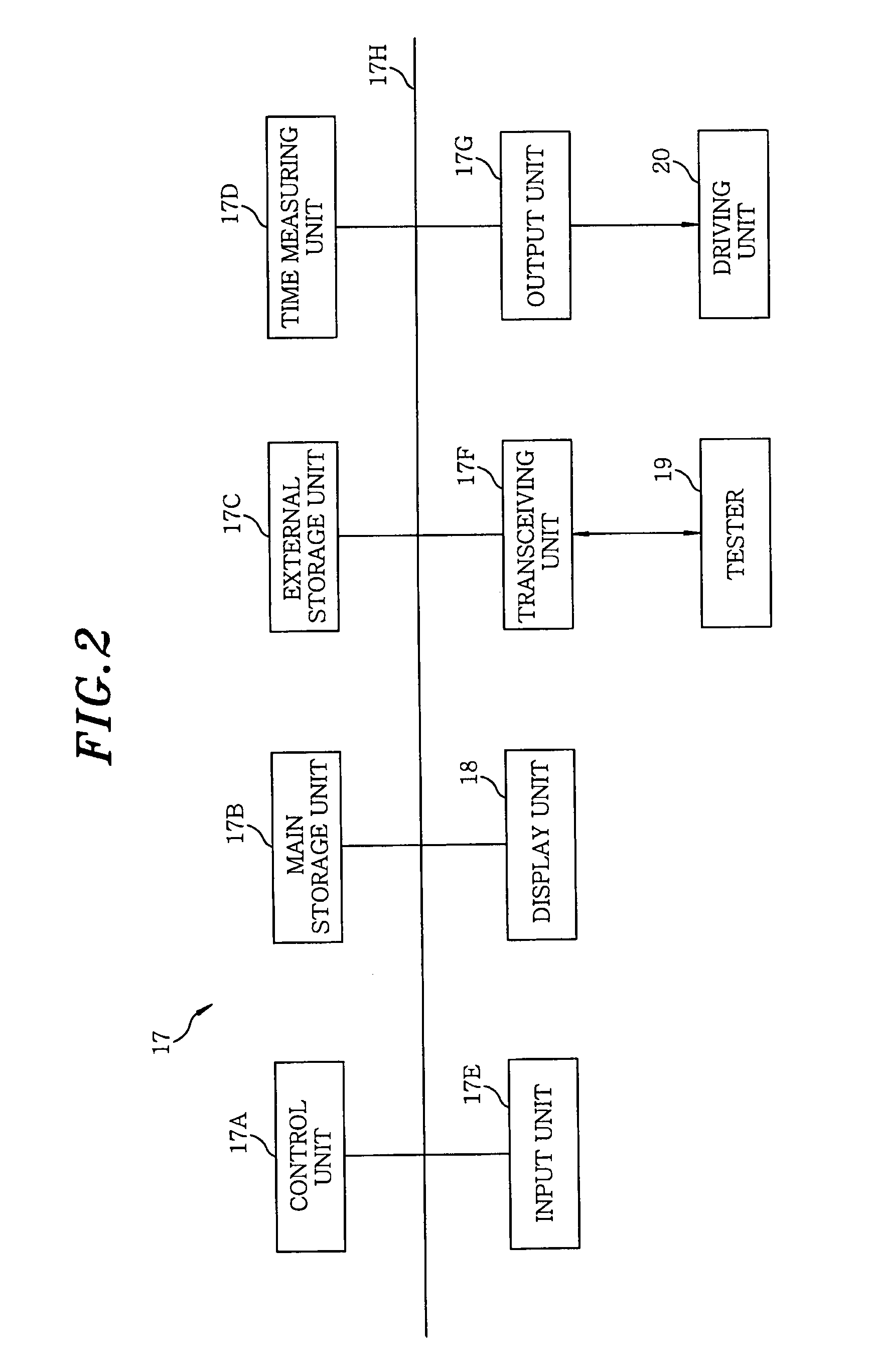

[0033]Hereinafter, a probe apparatus to which an inspecting method of this embodiment is applied will be explained with reference to FIGS. 1 and 2.

[0034]As shown in FIG. 1, a probe apparatus 10 includes: a loading unit 11 for transferring a wafer W as a target object to be inspected; and a prober chamber 12 provided near the loading unit 11 for inspecting electrical characteristics of the wafer W from the loading unit 11. The prober chamber 12 has: a mounting table 13 for mounting thereon the wafer W and moving in X, Y, Z and θ directions; a probe card 14 disposed above the mounting table 13; a test head T to be electrically contacted with the probe card 14 via an insert ring 15; an alignment mechanism 16 for aligning a plurality of probes 14A of the probe card 14 with the wafer W mounted on the mounting table 13; and a control device 17 mainly including a computer fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com