Alloy tool steel and its producing method and mold using it

A technology of alloy tool steel and manufacturing method, which is applied in the field of alloy tool steel and its manufacture and molds using it, and can solve problems such as early failure, low toughness, and insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

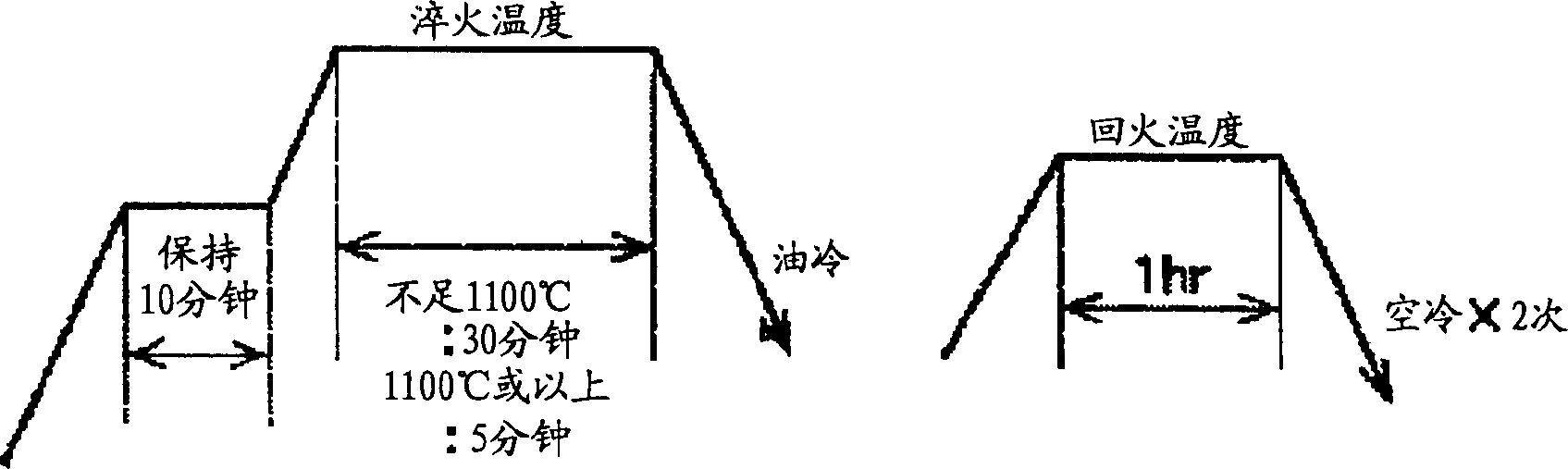

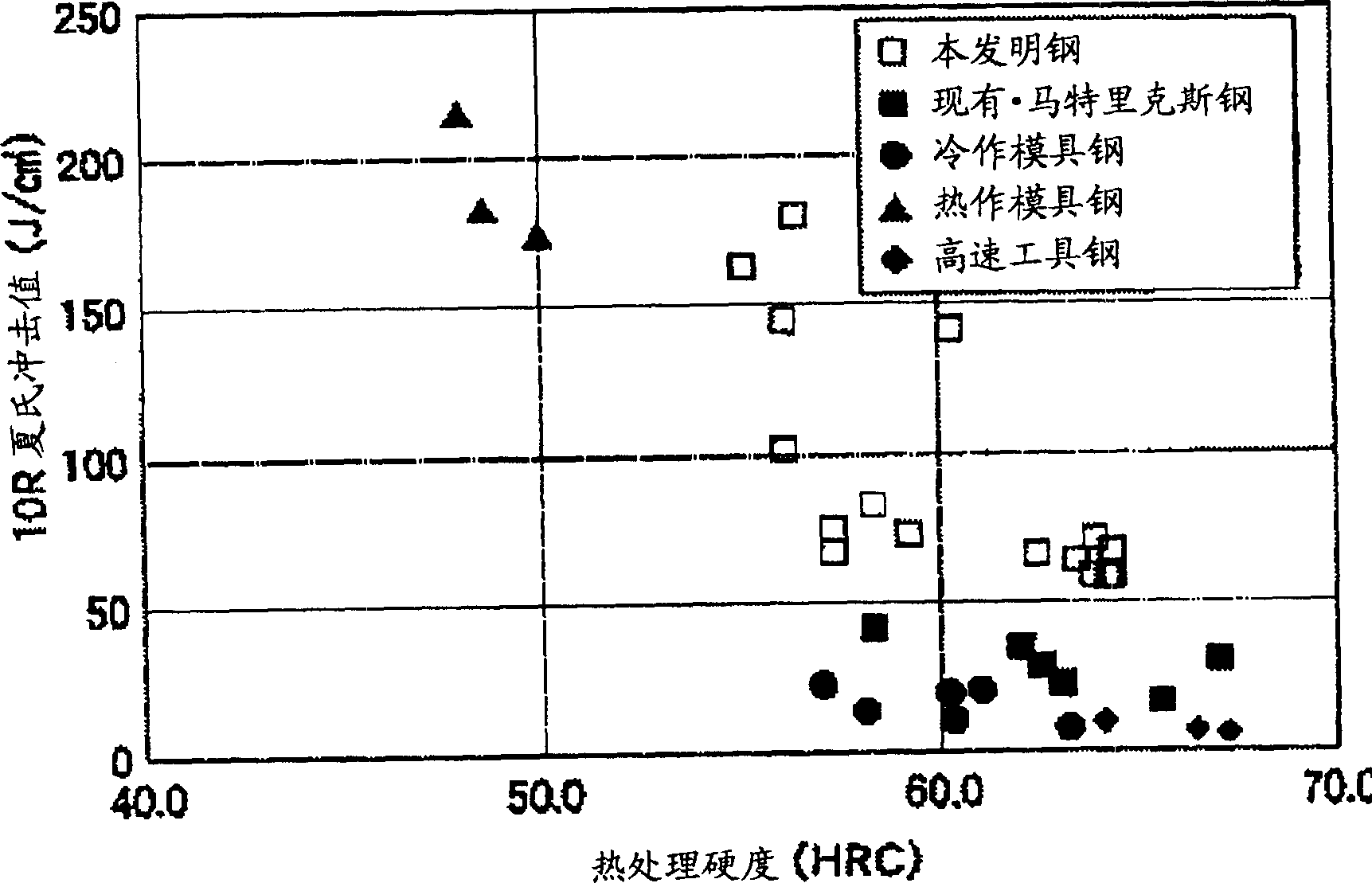

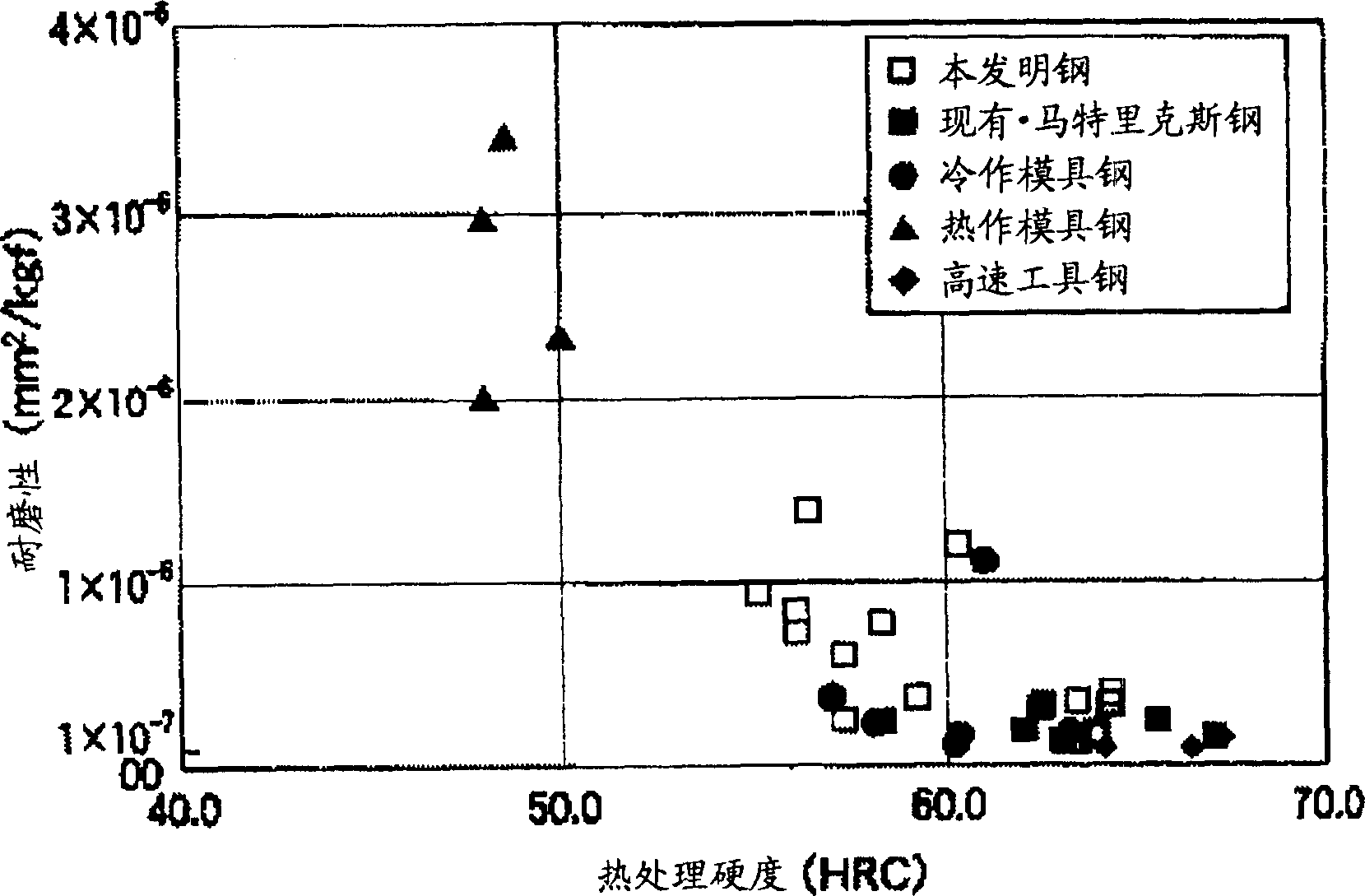

[0100] With a vacuum induction furnace of 150Kg, the steels of the examples of the present invention and the comparative examples shown in Table 2 of the composition shown in the following Table 1 were smelted and cast into ingots. The forging ratio is extended forging. From the material produced in this way, hardness test specimens, 10R Charpy impact test specimens, test specimens for Okoshi wear testers, and the following heat-treated bending specimens were produced, and figure 1 Quenching and tempering were performed at the temperature shown in the heat treatment characteristic curve shown in Table 3 and Table 4. These samples were used to carry out hardness, impact value, wear resistance, and heat treatment bending tests according to the following methods, and the results are shown in Table 3 and Table 4, and at the same time Figure 2 to Figure 5 In this table, the results of Table 3 and Table 4 are used to show the relationship between heat treatment hardness-impact val...

Embodiment 2

[0125] In the same manner as in the above-mentioned first example, steel samples of the examples of the present invention and the comparative examples shown in Table 5 having the composition shown in Table 6 below were prepared. and in figure 1 Quenching and tempering are performed at the heat treatment characteristic curve shown in and the temperatures shown in Table 7 and Table 8. These samples were used to carry out hardness, impact value, wear resistance, and heat treatment bending tests according to the following methods, and the results are shown in Table 7 and Table 8, and at the same time Figure 6 ~ Figure 9 In this table, the results of Table 7 and Table 8 are used to show the relationship between heat treatment hardness-impact value, heat treatment hardness-wear resistance, quenching temperature-heat treatment bending index, and impact value-wear resistance.

[0126] As shown in Table 5, high-speed tool steel (q~s) Weq and V additions are large. Cold work die stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com