Intermediate driving axle for propelling ship

An intermediate shaft and longitudinal axis technology, applied in the field of intermediate drive shafts, can solve the problems of high price, inconvenience and bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

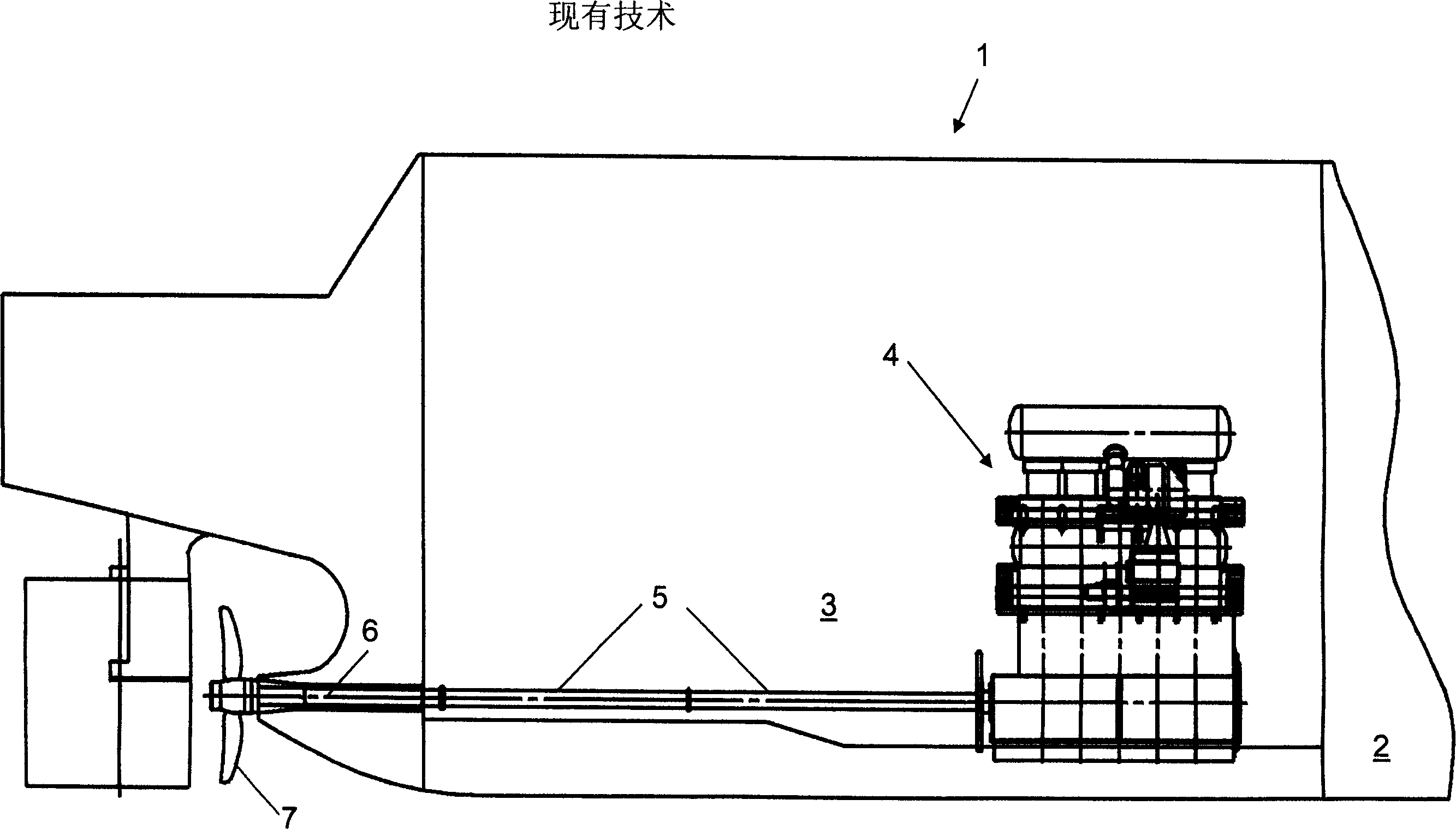

[0027] figure 1 A prior art hull 1 of a vessel with a cargo hold 2 and an engine room 3 is shown. A crosshead type 5-cylinder two-stroke engine 4 is located just behind the wall separating the engine compartment 3 from the cargo compartment 2 .

[0028] A solid and relatively long intermediate shaft 5 connects the output shaft of the engine 4 and the propulsion shaft 6 which drives the propeller 7 . The intermediate shaft has high torsional flexibility due to its long length. In this design of the ship's drive system, the level of overstress of the intermediate shaft due to torsional resonance is rarely the case.

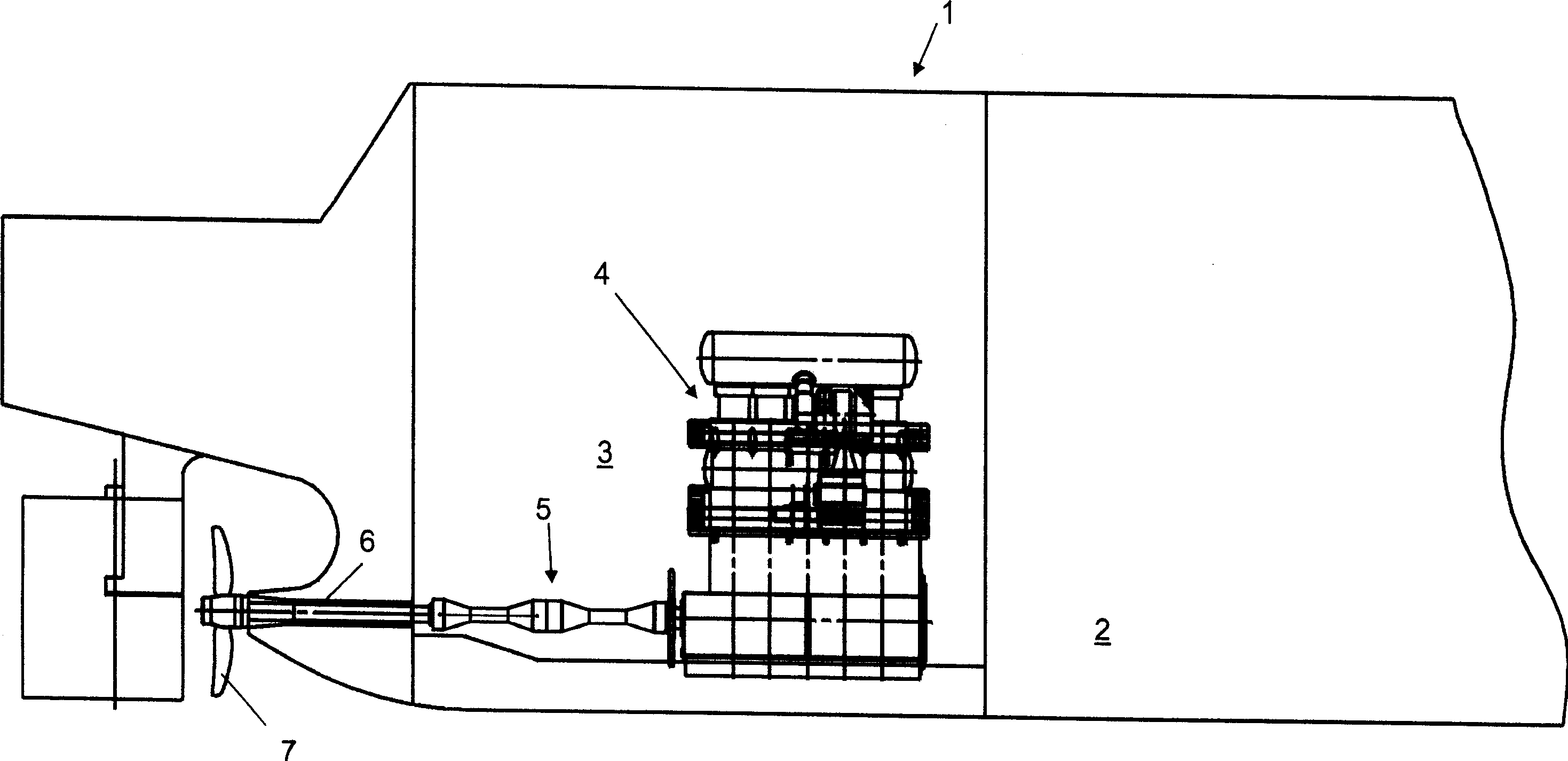

[0029] figure 2 Shown is a hull 1 of a vessel with a cargo hold 2 and an engine room 3 according to an embodiment of the invention. engine compartment 3 ratio figure 1 The engine compartment of the embodiment shown in is shorter so that a larger cargo compartment 2 is possible even with other parameters being the same.

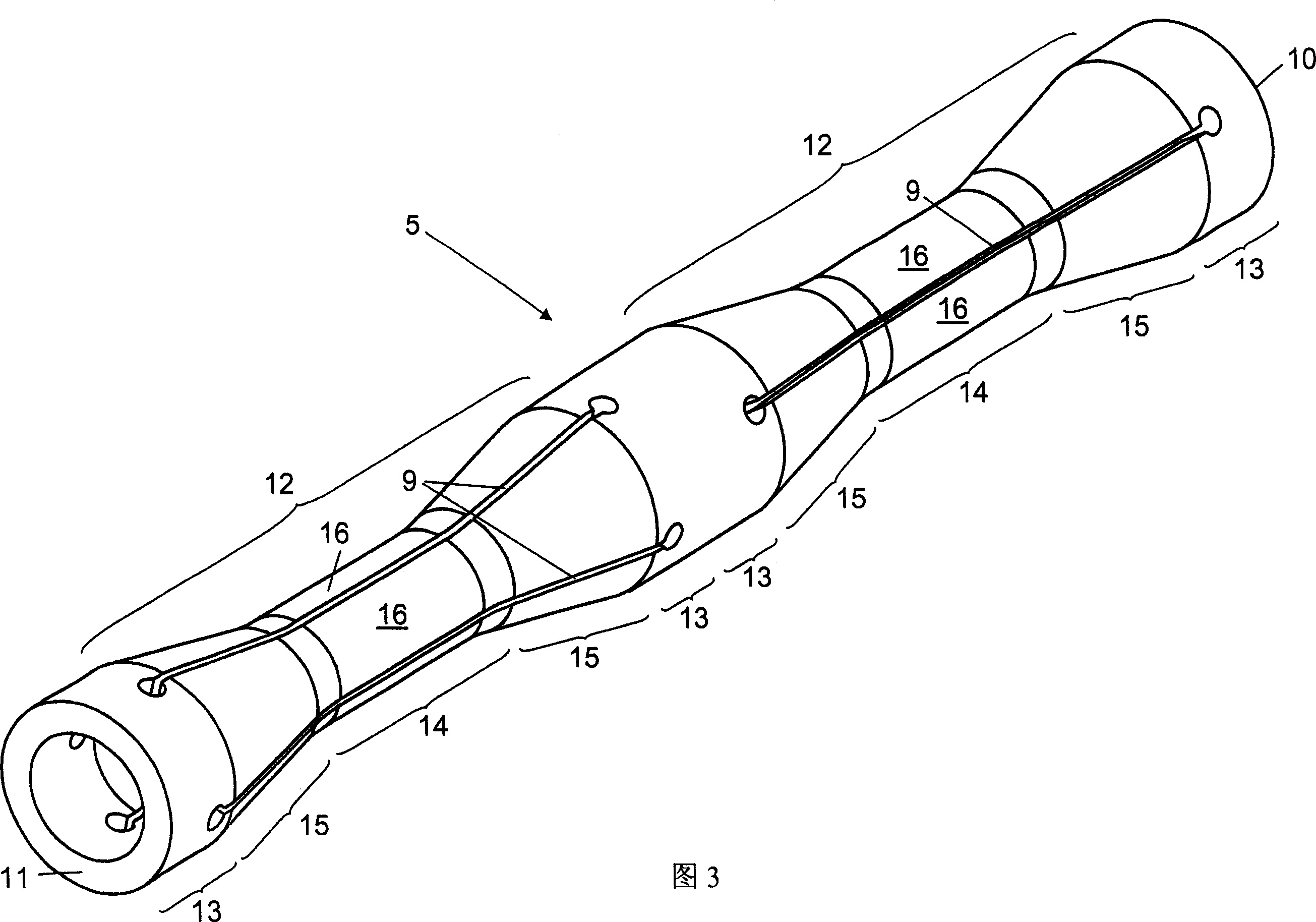

[0030] A large crosshead-type 5-cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com