Inclined cutting saw with light projector

A technology of miter saw and light projection, applied in the direction of sawing machine device, attachment device of sawing machine, circular saw, etc., can solve the problems of reducing the efficiency and trouble of sawing workpiece W, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

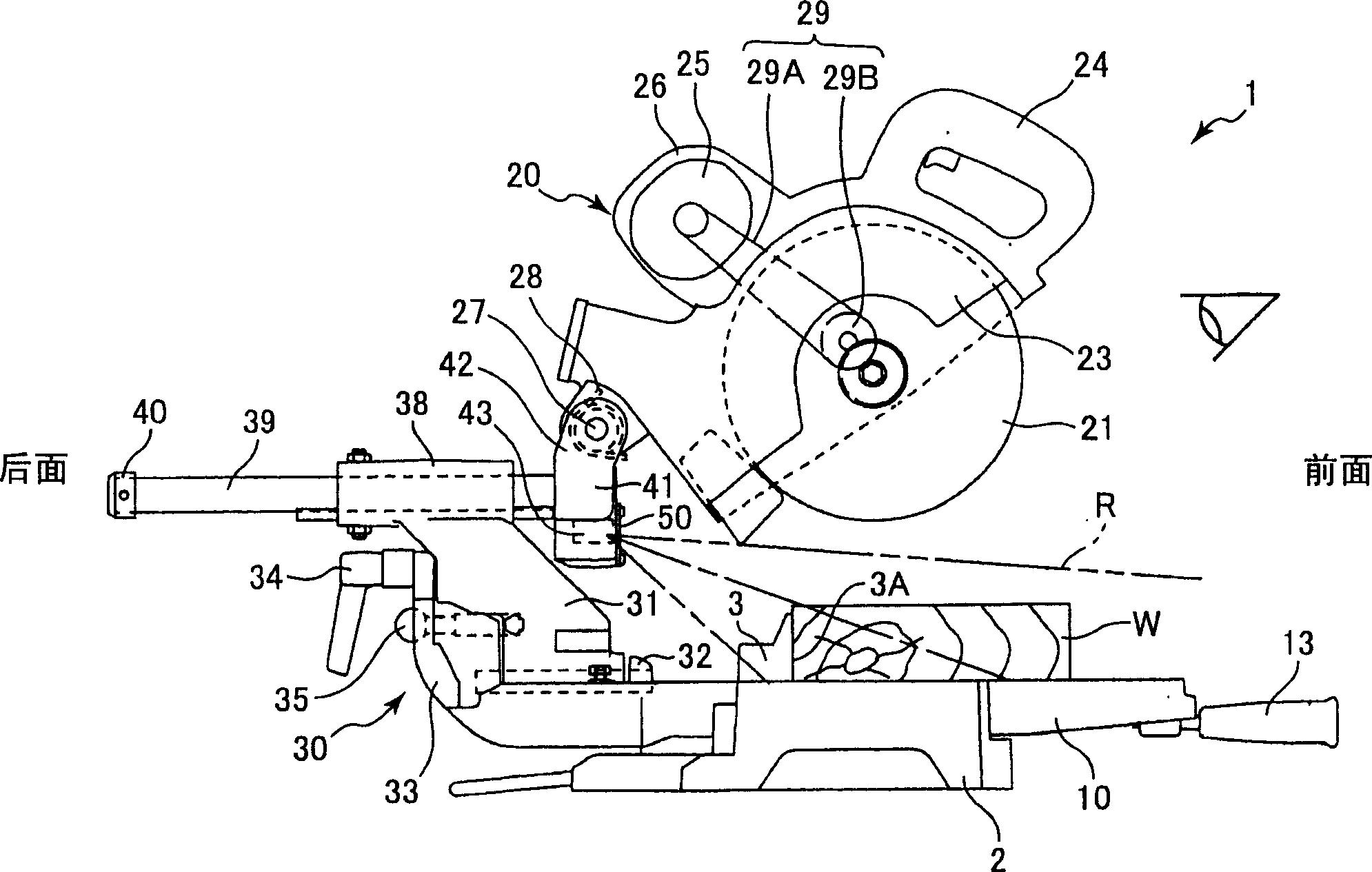

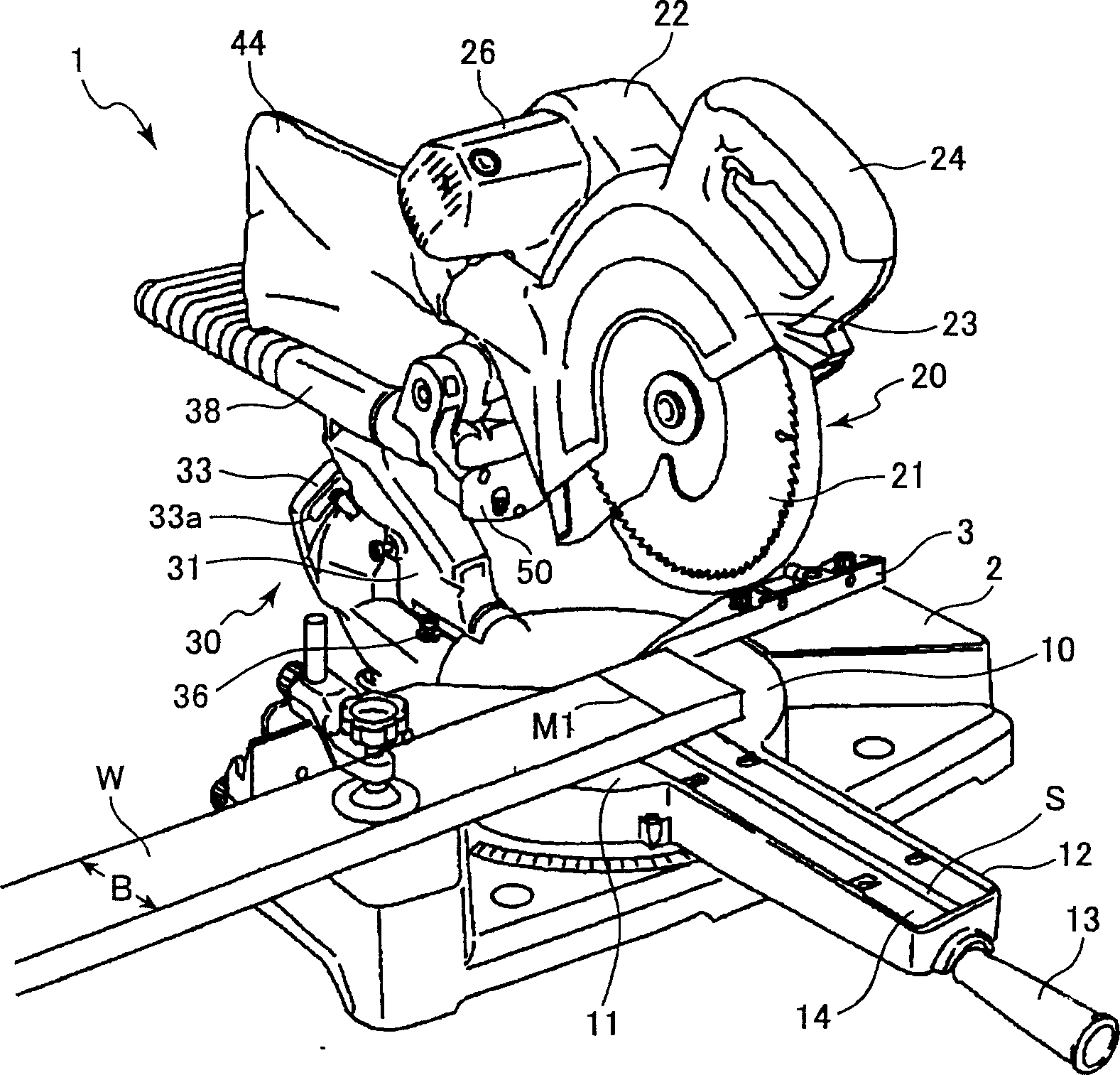

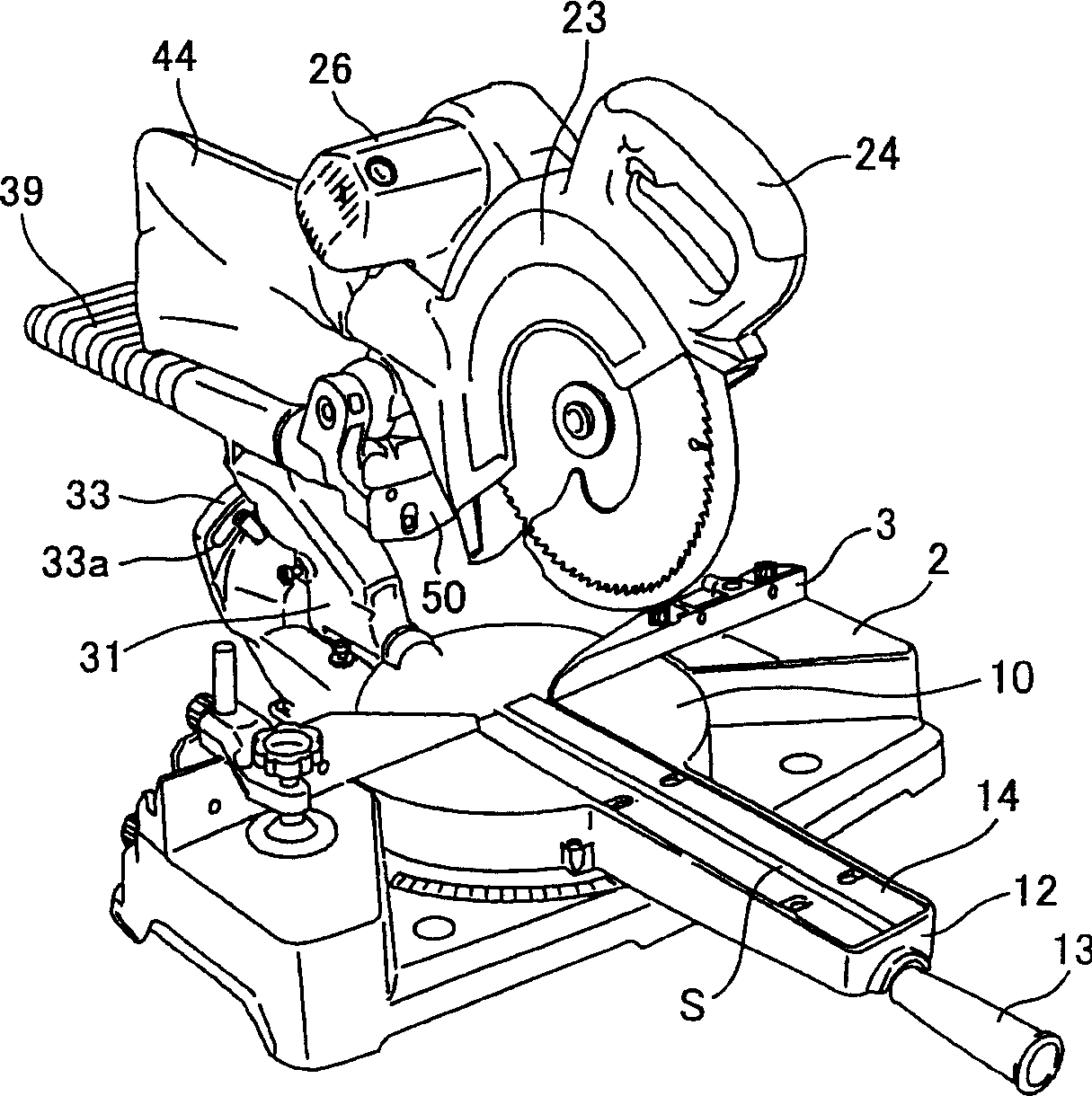

[0024] refer to Figure 1 to Figure 8 , a miter saw according to a first embodiment of the present invention will be described. The miter saw 1 generally includes a base 2 , a turntable 10 , a cutting device 20 and a supporting device 30 . The turntable 10 is rotatably mounted on the base 2, and is used to mount the workpiece on the base 2 together with the base 2. The cutting device 20 supports a circular saw blade 21 . The support device 30 extends from the turntable 10 for movably supporting the cutting device 20 at a position above the turntable 10 . The turntable 10 is embedded in the central part of the base 2 and can rotate on a horizontal plane. The upper surface of the turntable 10 is flush with the upper surface of the base 2 . Workpieces W such as wood and timber can be arranged on the upper surface of the base 2 and the turntable 10 , and the guardrail 3 extending along the diameter direction of the turntable 10 is fixed on the upper surface of the base 2 . Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap