Plasma display panel and method for manufacturing same

A plasma display and manufacturing method technology, applied in the direction of alternating current plasma display panels, static indicators, cold cathode manufacturing, etc., can solve the problem that the discharge area cannot be effectively used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

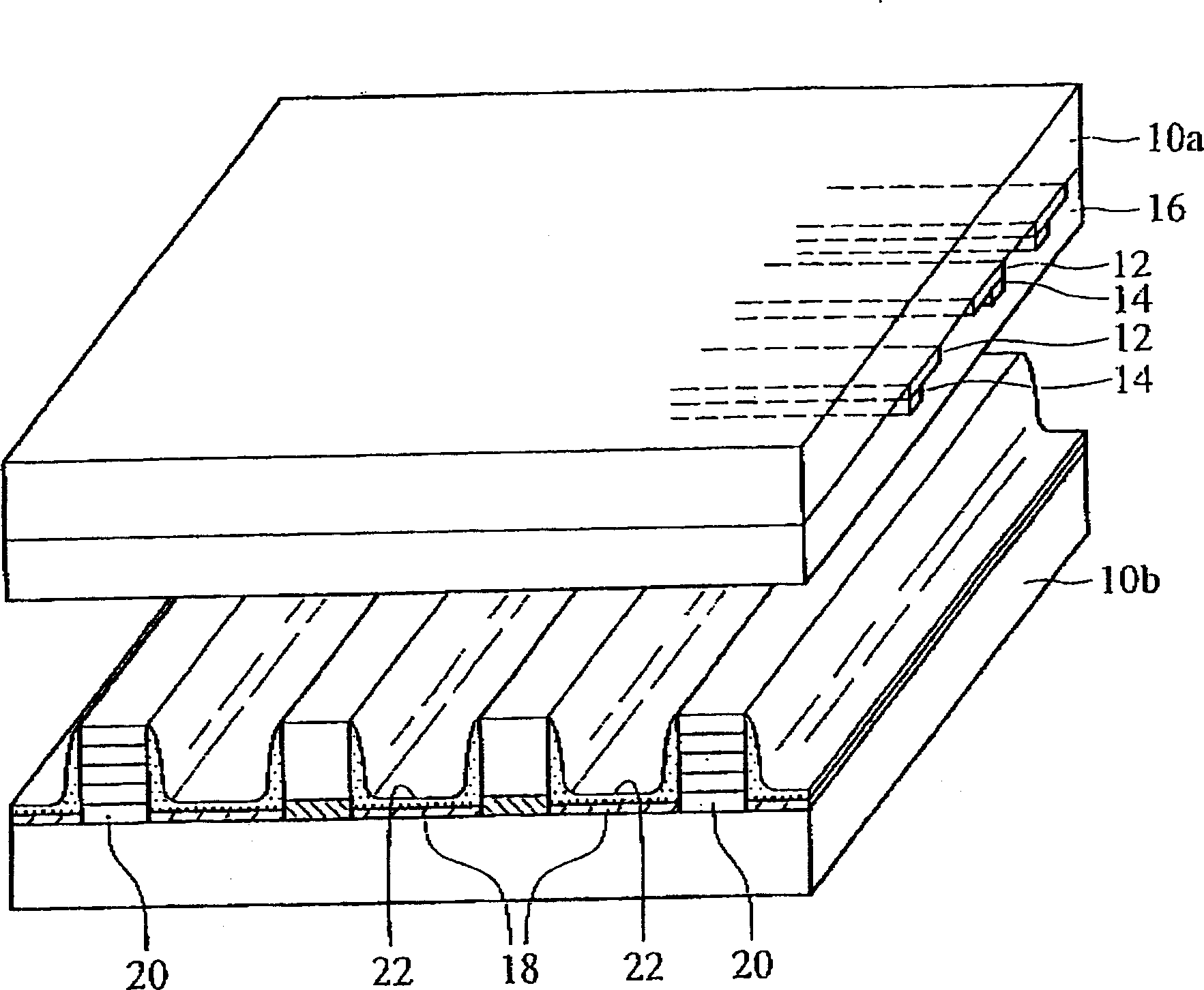

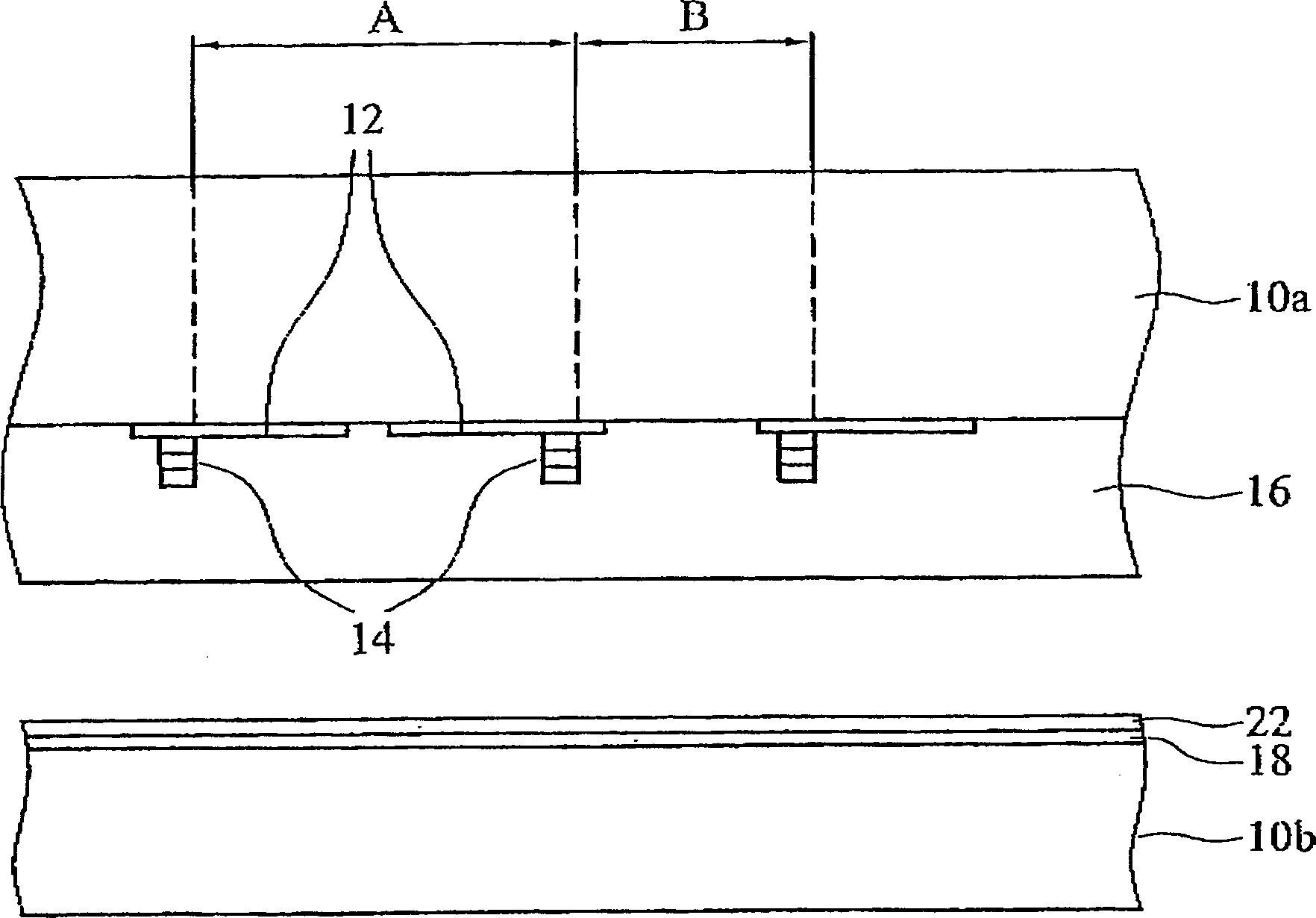

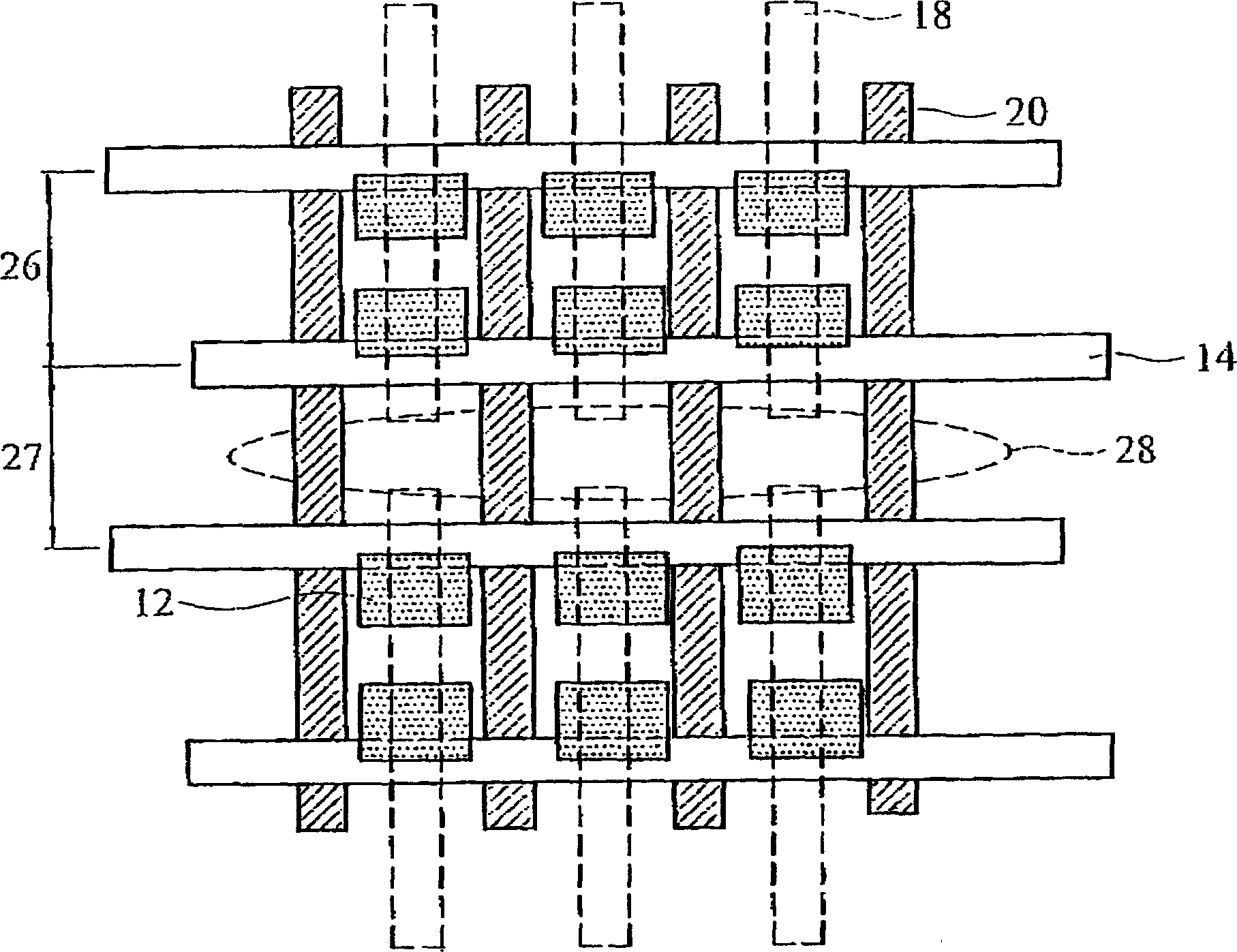

[0026] The invention discloses a plasma display panel, which is composed of a closed barrier structure and a delta sub-pixel arrangement. Please refer to Figure 4a and 4b The barrier ribs 40 can be divided into row barrier ribs 42 and column barrier ribs 44 and divided into a plurality of polygons or rectangles to define sub-pixel units with red, green, and blue (RGB) phosphor layers disposed therein. 46. In particular, each sub-pixel unit 46 has a unit area defined by the intersection of the row barrier wall 42 and the column barrier wall 44 . The RGB color pixel is composed of a set of red, green and blue sub-pixel units 46 arranged in a triangle shape. Each adjacent color pixel combined with RGB sub-pixel units can be reversely arranged into a continuous sequence. The closed barrier rib structure eliminates dark areas and increases luminous efficiency due to increased phosphorescence area and aperture ratio. The discharge error in the double scanning area can be avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com