Utrafiltration apparatus and its operation guide

An ultrafilter and outlet technology, applied in the field of ultrafiltration devices, can solve problems such as difficulty in finding a matching feed pump and circulation pump, deterioration, etc.

Inactive Publication Date: 2004-12-29

上海蓝景膜技术工程有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

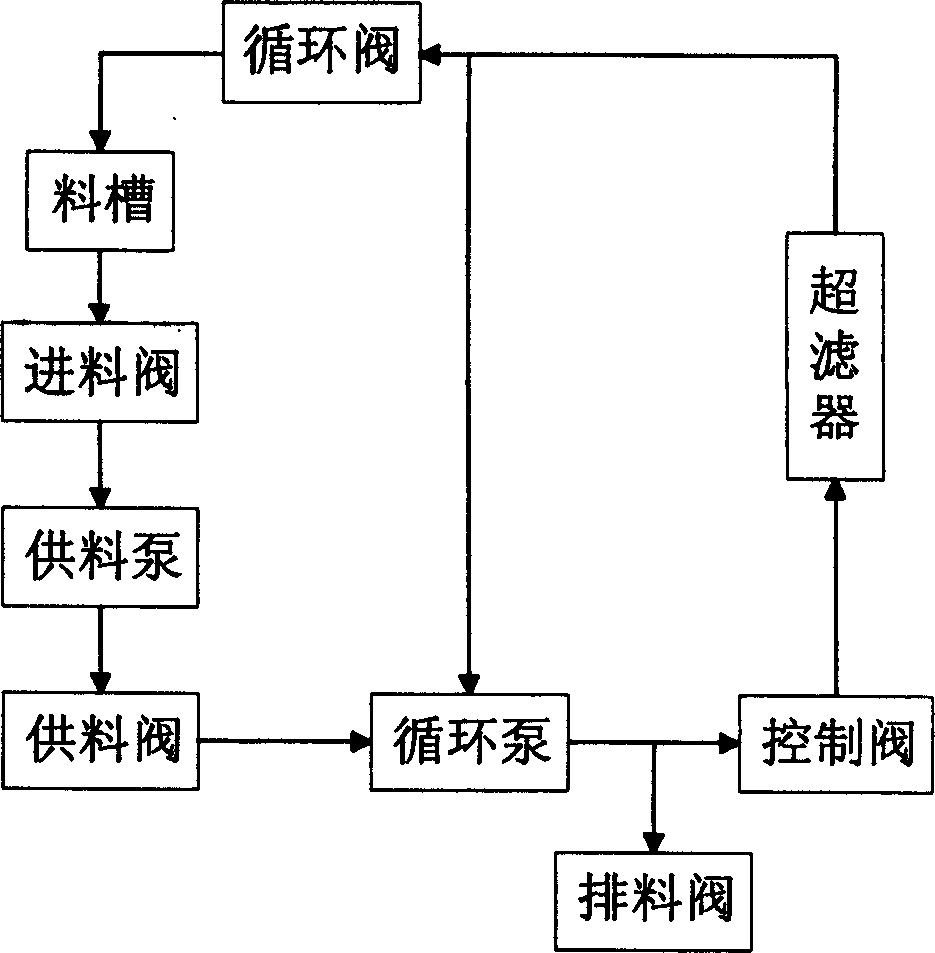

figure 2 The dual-pump ultrafiltration device shown is suitable for industrial production operations. Due to the small amount of feed liquid in the laboratory, it is difficult to find a well-matched feed pump and circulation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

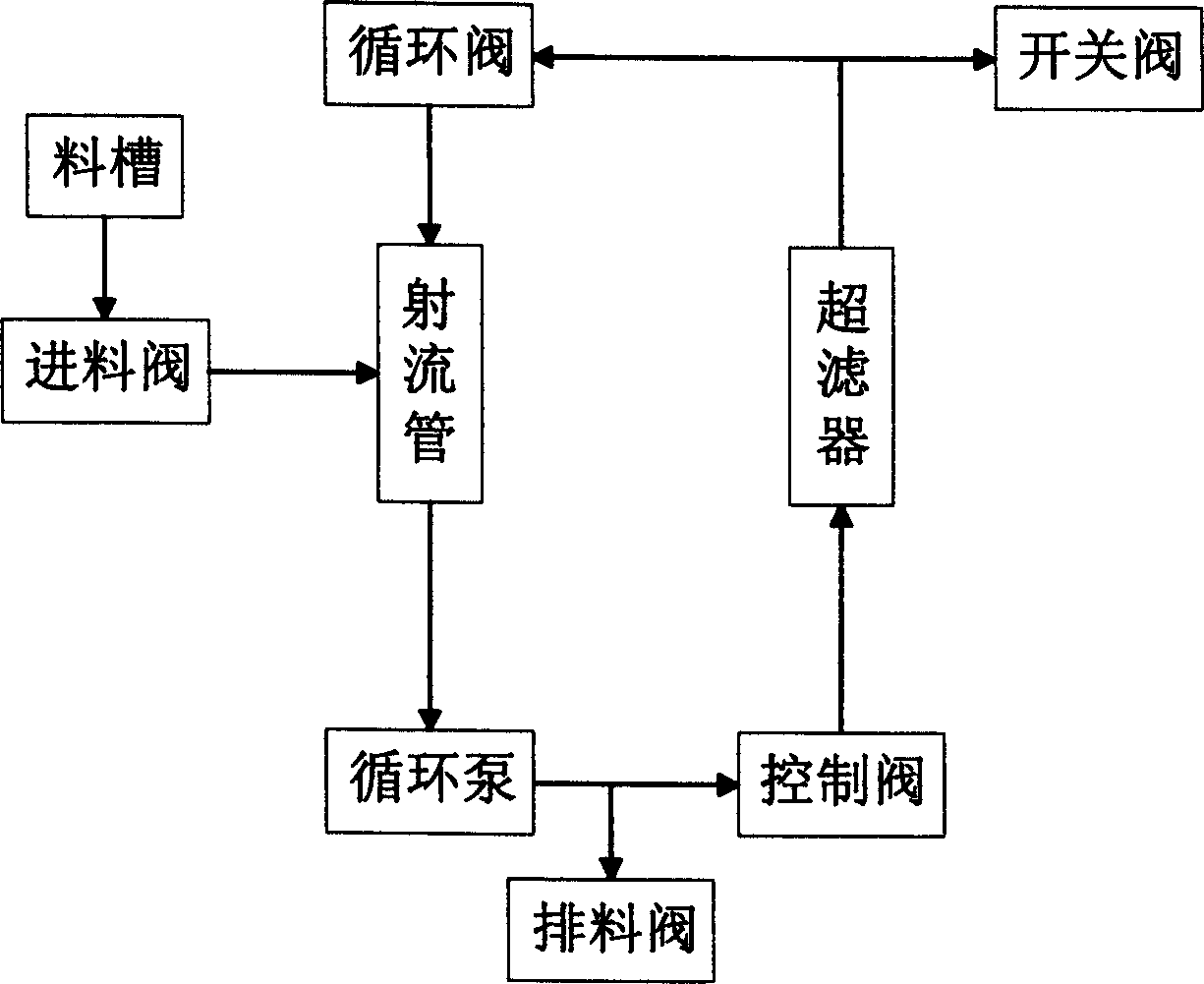

The present invention is one kind of ultrafiltering apparatus and its application method. The ultrafilter includes material tank, circulating pump, ultrafilter and jet pipe, with the circulating pump and the ultrafilter constituting closed loop ultrafiltering system. Controlling the valve connected to the outlet of the ultrafilter can realize batched intermittent operation and continuous operation. The concentrated liquid is not returned directly to the material tank and contacted with outer air, and this can avoid the oxidizing deterioration of some air-sensitive matter in the liquid to be processed, and avoid some easy-to-bubble matter to bubble and overflow, resulting in shortened processing period.

Description

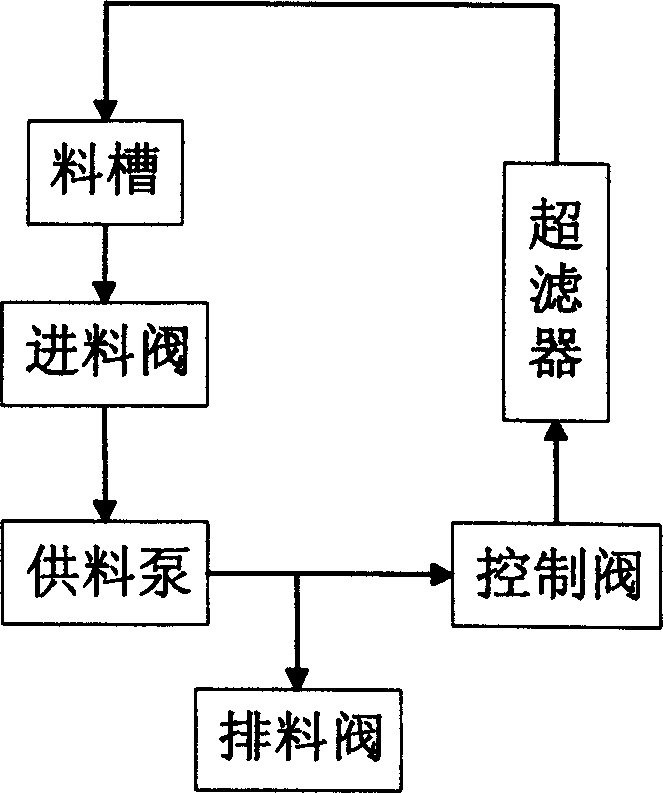

technical field [0001] The invention relates to an ultrafiltration device and an application method thereof, in particular to an ultrafiltration device using a jet tube to self-suction feed, and a method for applying the device. Background technique [0002] In the unit operation of ultrafiltration, there have always been two structures, one structure such as figure 1 Shown: The feed liquid is supplied to the feed pump from the feed tank through the feed valve, and the feed liquid is pumped into the ultrafilter by the feed pump through the control valve. Under the pressure, part of the feed liquid becomes ultrafiltrate, and the other part does not. The permeated feed liquid is enriched with macromolecular substances such as particles, colloids, proteins, bacteria, etc., and returns to the feed tank as a concentrated liquid. The material in the trough is continuously concentrated, and when it reaches a certain level, the operation is stopped, an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D61/18

Inventor 刘寿山祝振鑫周国云

Owner 上海蓝景膜技术工程有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com