Method of manufacturing turbine frame of VGS type turbo charger, turbine frame manufactured by the method, exhaust gas guide assembly of VGS type turbo charger using the turbine frame and VGS type tur

A technology of turbocharger and manufacturing method, which is applied in the direction of engine manufacturing, gas turbine device, machine/engine, etc., can solve the problems of labor-intensive processing, difficult-to-cut materials, etc., achieve high heat resistance, high-efficiency processing, and reduce wrinkle skin Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

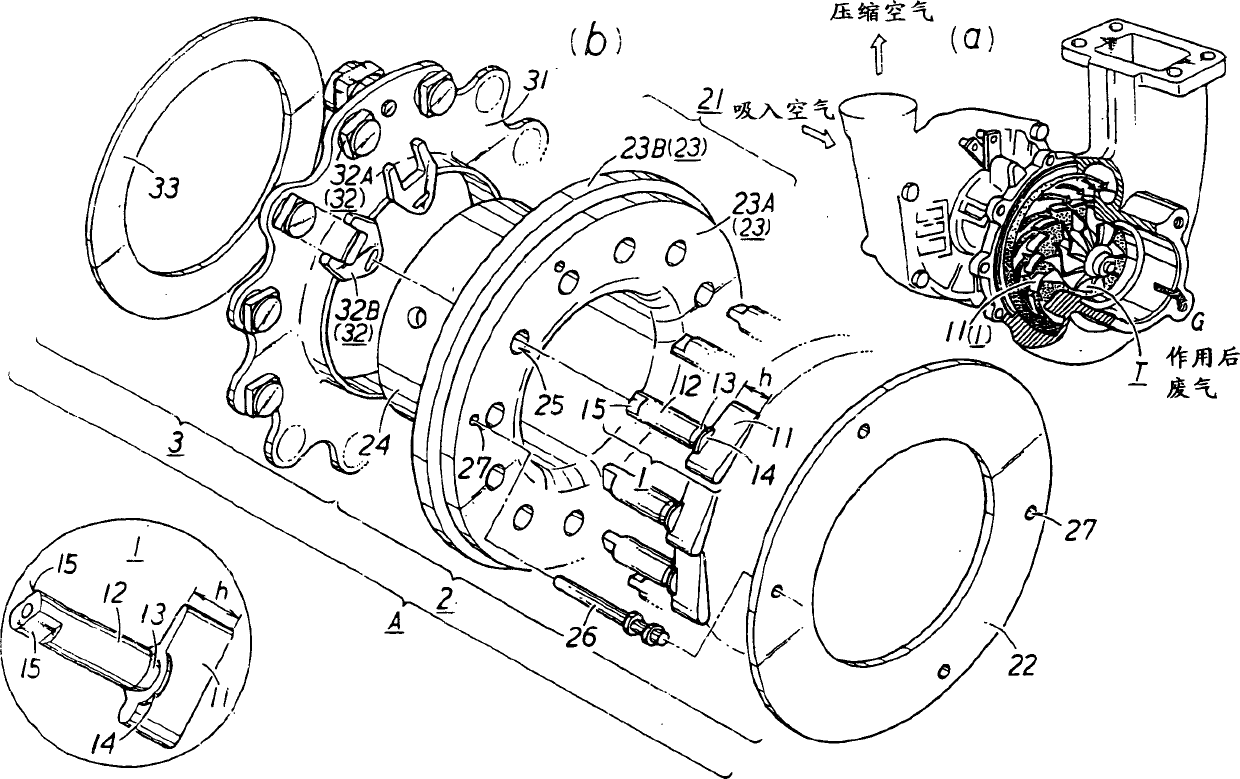

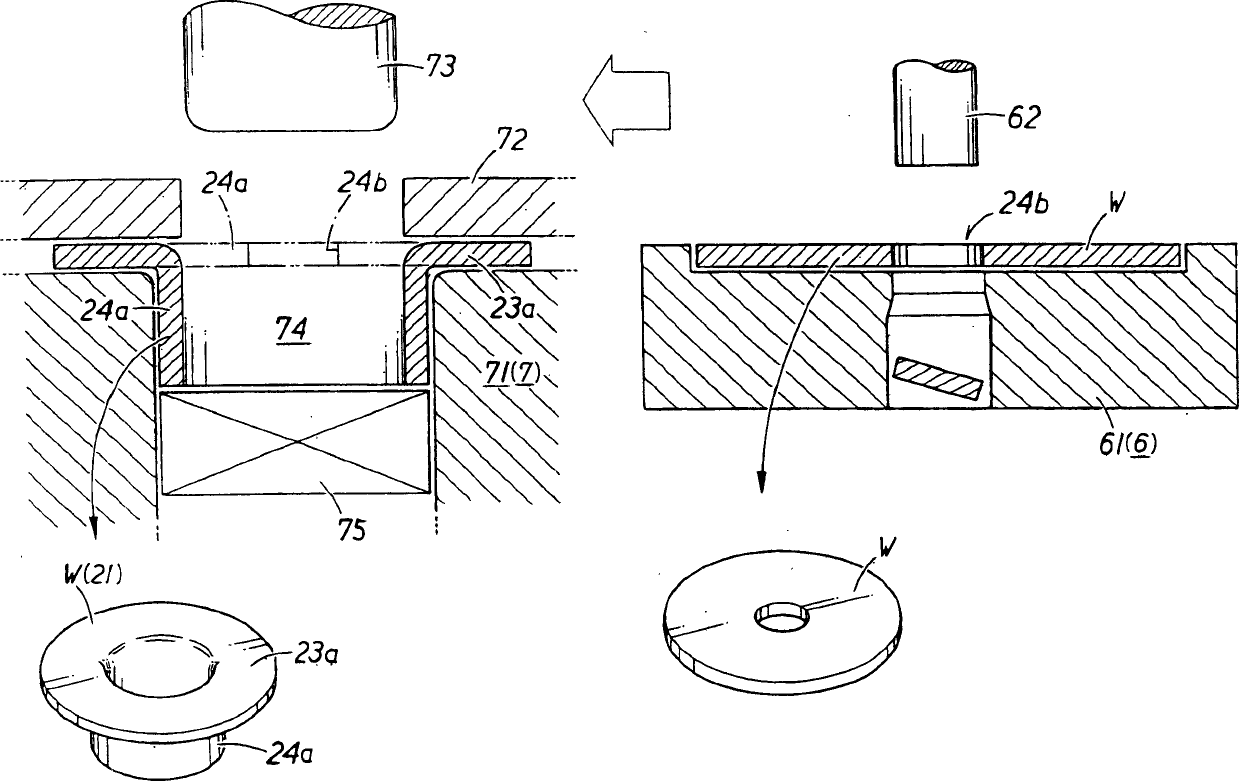

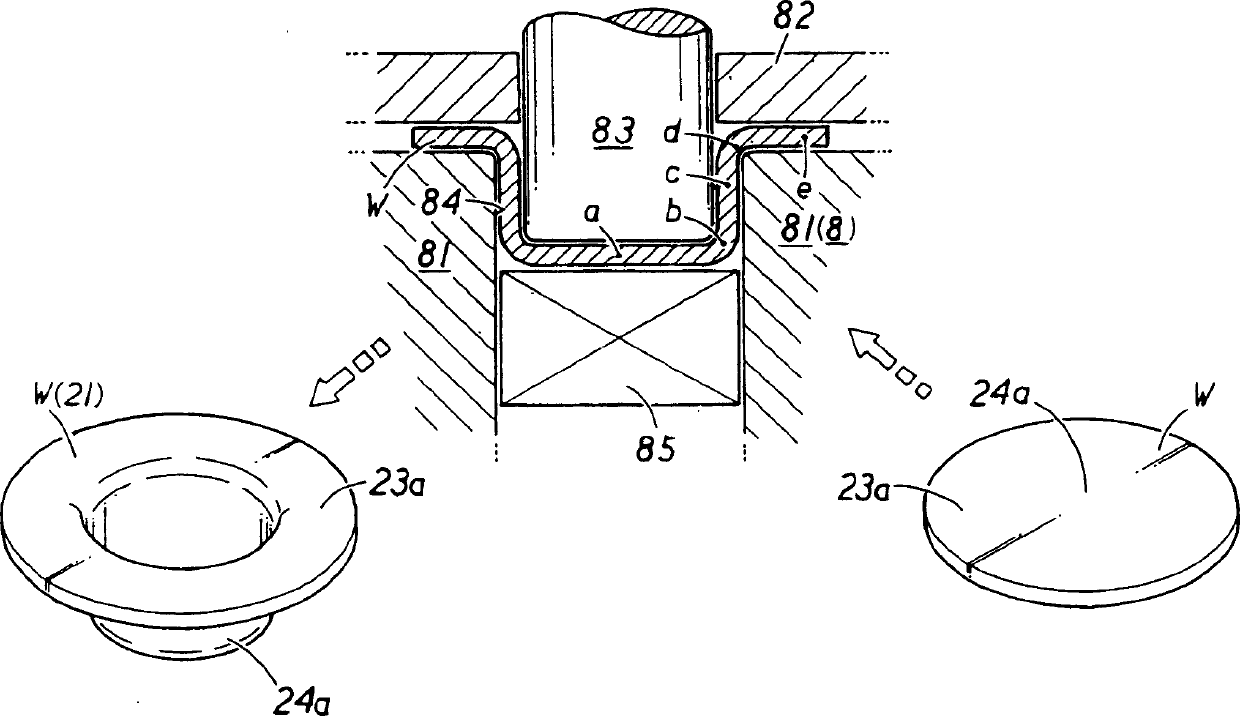

[0033] The present invention will be described below based on the illustrated embodiments. When explaining, the exhaust duct assembly A in the VGS type turbocharger using the turbine frame 2 of the present invention will be described, and the turbine frame 2 will be mentioned together, and then, the manufacturing method of the turbine frame will be described. .

[0034] The exhaust duct assembly A, especially when the engine is running at low speed, properly concentrates the exhaust gas G to adjust the exhaust gas flow, as shown in Fig. A plurality of variable vanes 1 for the flow rate, a turbine frame 2 for rotatably holding the variable vanes 1 , and a variable mechanism 3 for rotating the variable vanes 1 for appropriately setting the flow rate of the exhaust gas G by a certain angle. Each component will be described below.

[0035] First, the variable vane 1 will be described. As an example, as shown in FIG. 1, a plurality of these components are arranged in an arc shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com