Method of manufacturing turbine frame of VGS type turbo charger

一种涡轮增压器、制造方法的技术,应用在发动机制造、燃气轮机装置、机器/发动机等方向,能够解决难切削材料、加工费工夫等问题,达到高效加工、高耐热性、精度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

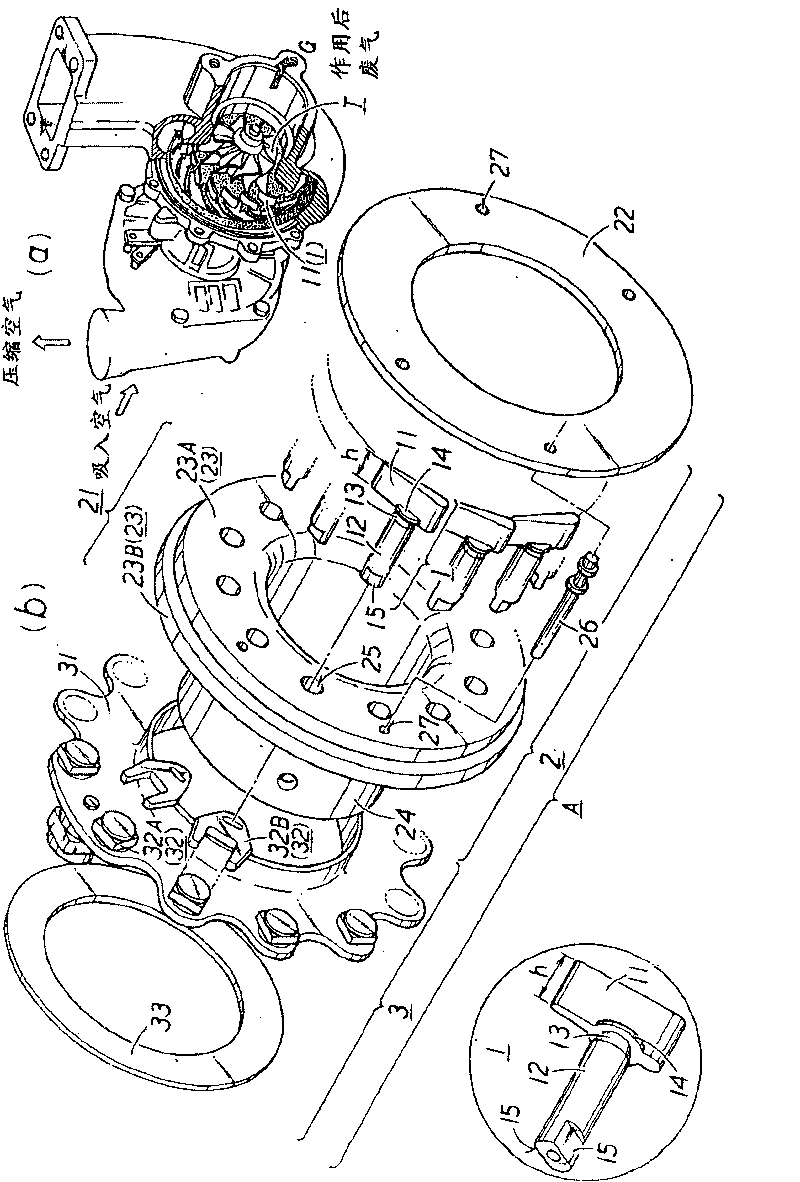

[0033] The present invention will be described below based on the illustrated embodiments. When explaining, the exhaust duct assembly A in the VGS type turbocharger using the turbine frame 2 of the present invention will be described, and the turbine frame 2 will be mentioned together, and then, the manufacturing method of the turbine frame will be described. .

[0034] Exhaust duct assembly A, especially when the engine is running at low speed to properly concentrate the exhaust gas G to regulate the exhaust flow, as an example such as figure 1 As shown in , there are a plurality of variable vanes 1 provided on the outer periphery of the exhaust turbine T and substantially setting the flow rate of exhaust gas, a turbine frame 2 that rotatably holds the variable vanes 1 , and makes the exhaust gas G to be appropriately set The variable blade 1 of the flow rate is formed by rotating the variable mechanism 3 at a certain angle. Each component will be described below.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com