Vulcaizing machine for repairing auto tire

A technology of automobile tires and vulcanizing machines, which is applied in the field of tire repairing and vulcanizing devices, which can solve the problems of not being able to automatically adjust the pressure, increase the user's power consumption cost, and burnt, etc., and achieve the effects of easy manufacturing and promotion, good vulcanization effect, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

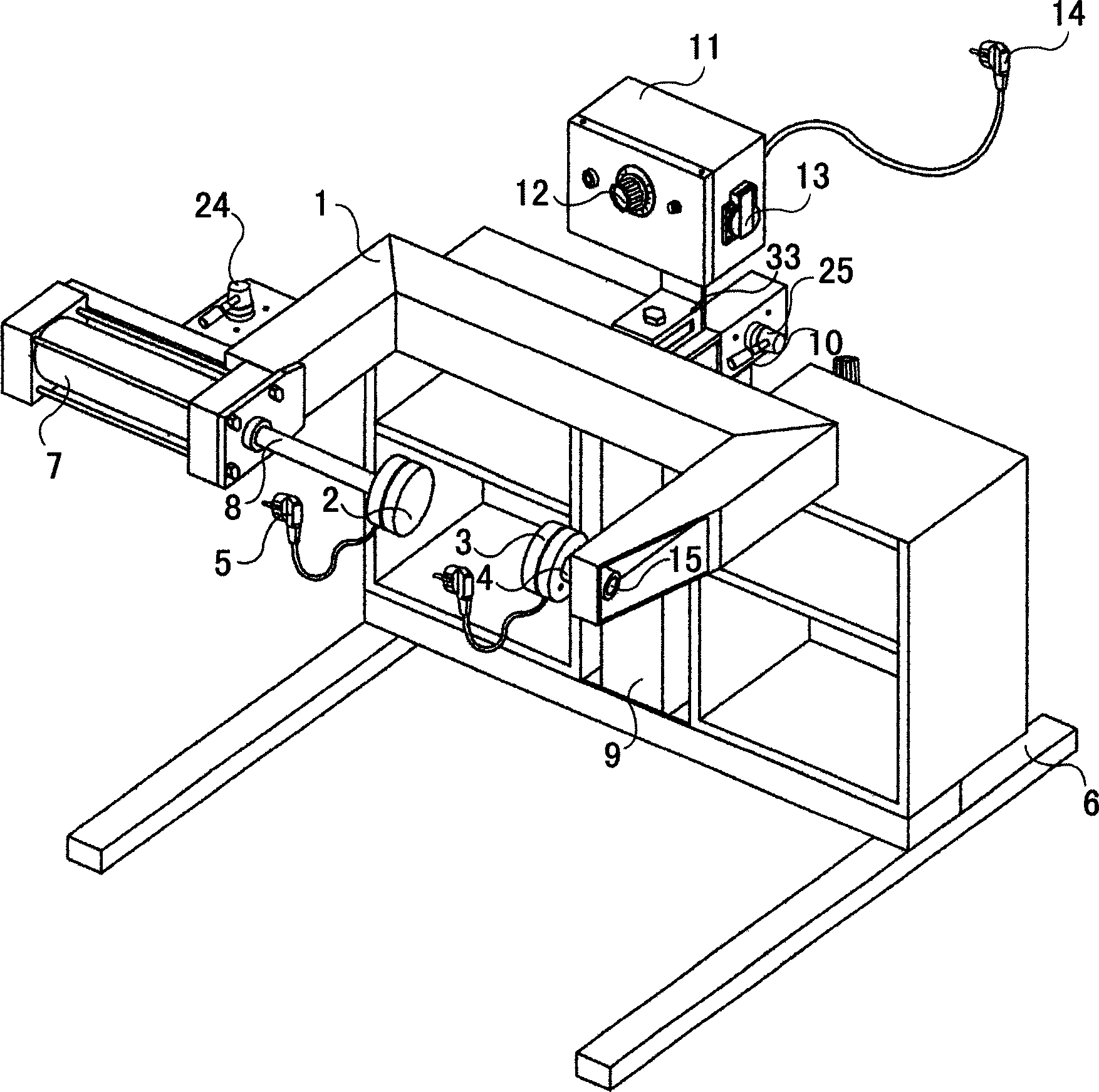

[0027] Such as figure 1 As shown, the automobile tire repair vulcanizer in this preferred embodiment includes a vulcanizing device, a vulcanizing device fixing mechanism and a vulcanizing device lifting mechanism, and the vulcanizing device is laterally fixed on the vulcanizing device fixing mechanism through the vulcanizing device lifting mechanism.

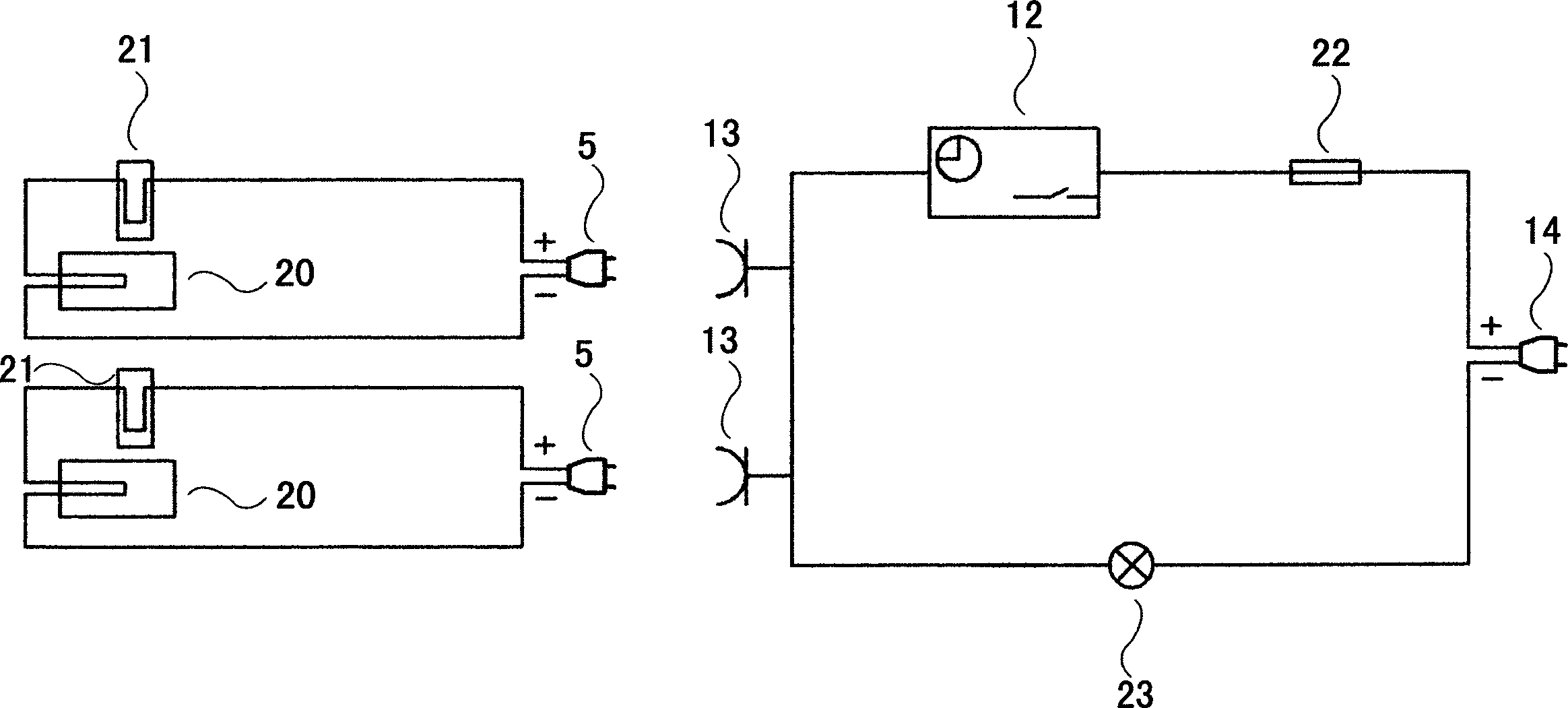

[0028] The vulcanization device is composed of a fixed frame 1, a left heating plate 2, a right heating plate 3, a driving mechanism, a fixing piece 4 and two power plugs 5, and the right heating plate 3 is fixed on the fixing frame 1 through the fixing piece 4.

[0029] The drive mechanism adopts a pneumatic drive mechanism, including a cylinder 7, an air source switch 24 and a drive rod 8. The cylinder 7 is located on the fixed frame 1, and one end of the drive rod 8 is connected to the cylinder 7, and the other end is connected to the left heating plate 2.

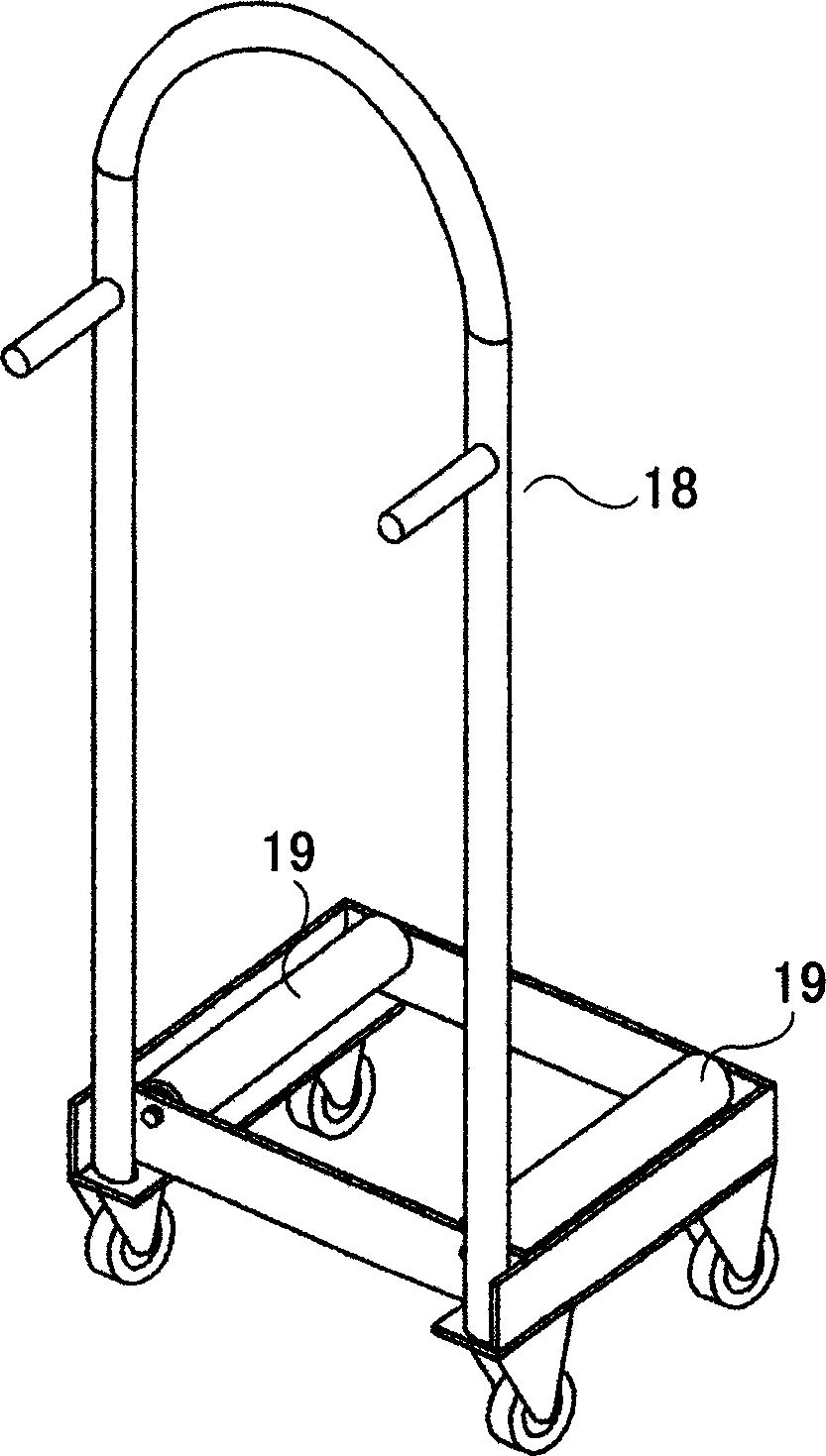

[0030] The fixing mechanism of the vulcanizing device is a movable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com