Turn-up bladder vulcanizing device and vulcanizing method

A bladder and vulcanization mold technology, applied in the field of tire building, can solve the problems of air gap affecting vulcanization effect, product influence, rubber product fatigue, etc., and achieve the effect of improving vulcanization heating effect, long product service life, and uniform vulcanization degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0063] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0064] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

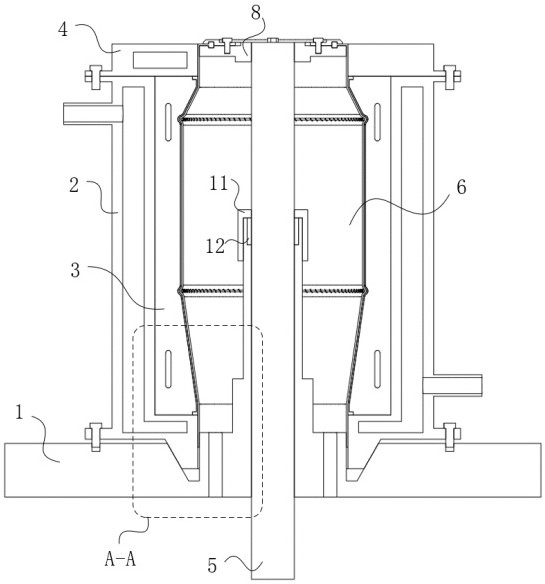

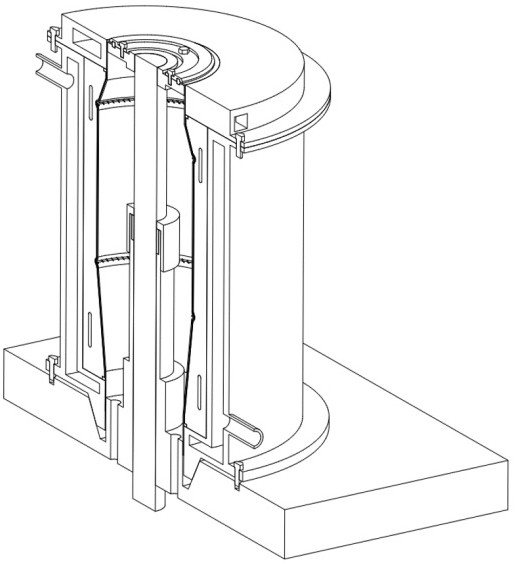

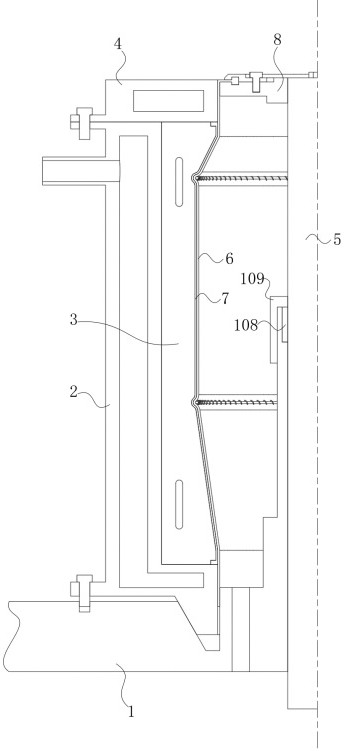

[0066] This embodiment provides a reverse-encapsulation bladder vulcanization device, comprising a base 1, a heating jacket 2, a vulcanization mold 3, an upper platen 4 and a vulcanization bladder 6, the upper platen 4 is fixed on the top of the heating jacket 2, the bottom of the heating jacket 2 is connected to the base 1 is fixed, the vulcanization mold 3 is installed in the heating jacket 2, which has the outer surface of the turned-up capsule and the outer surface of the spigot, the vulcanization bladder 6 is installed in the vulcanization mold 3, and has the inner surface of the turned-up capsule and the inner side of the slit On the surface, the heating jacket 2 has a cylindrical structure, and a first flange 24 and a second flange 25 are respectively arranged below and above the cylinder body 21. The cylinder body 21 has a first flow path 201 inside, and the first flow path 201 is L-shaped. The annular flow path communicates with the first inlet 22 and the first outlet ...

Embodiment 2

[0076] The first bladder bend 67 and the second bladder bend 68 in the vulcanization bladder 6 are provided with a support spring 69a, and the support spring 69a is vulcanized and solidified together with the first bladder bend 67 and the bladder second bend 68 .

[0077] A kind of optimized vulcanization bladder 6 is provided in the present embodiment, and support spring 69a is set at two bends of vulcanization bladder 6, and this support spring 69a can provide good resistance to the bend of turn-up capsule in the vulcanization process. The supporting function makes the bending part of the turn-up capsule less likely to be deformed during the vulcanization process. Simultaneously, when the reverse-wrapped capsule is taken and placed, the vulcanizing bladder 6 needs to be stretched, so that the middle part of the capsule body shrinks, which is convenient for taking and placing the reverse-wrapped capsule. Contraction occurs in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com