Selenium-coordinated dimercaptothiadiazole as well as preparation method and application thereof

A dimercaptothiadiazole and coordination technology, applied in the field of rubber vulcanization aids, can solve the problems of high toxicity, sensitization, and irritation of accelerator M, and achieve excellent vulcanization acceleration effect, short reaction time, The effect of high synthetic yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

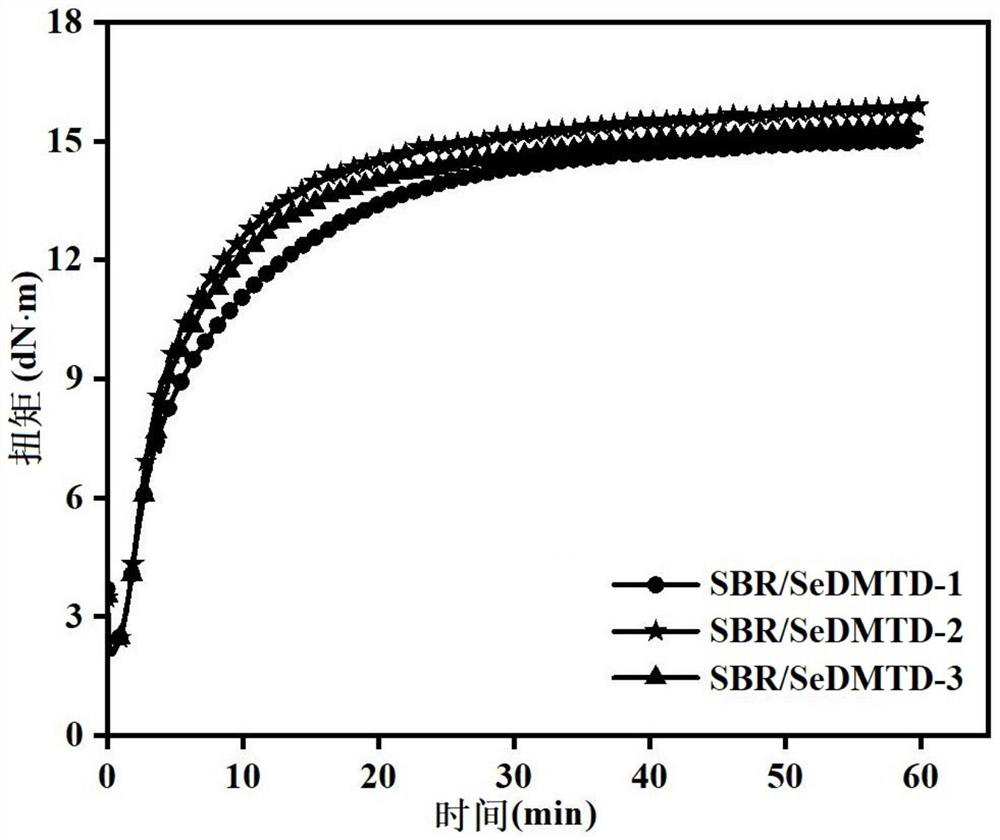

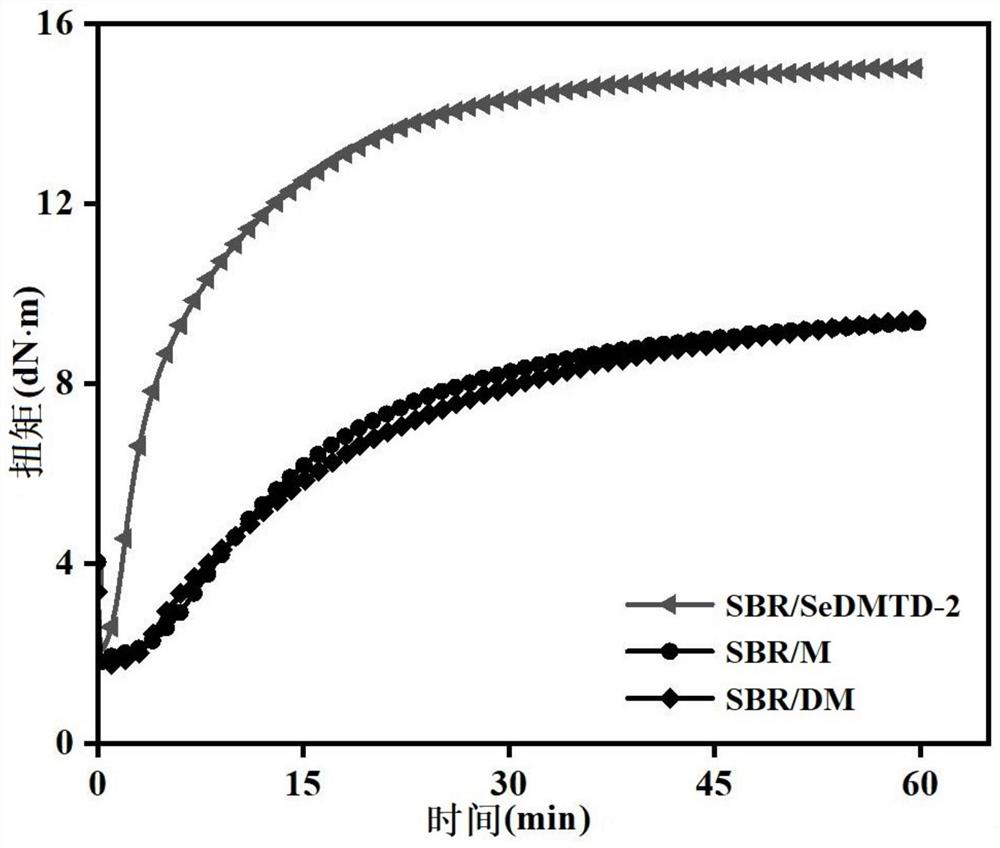

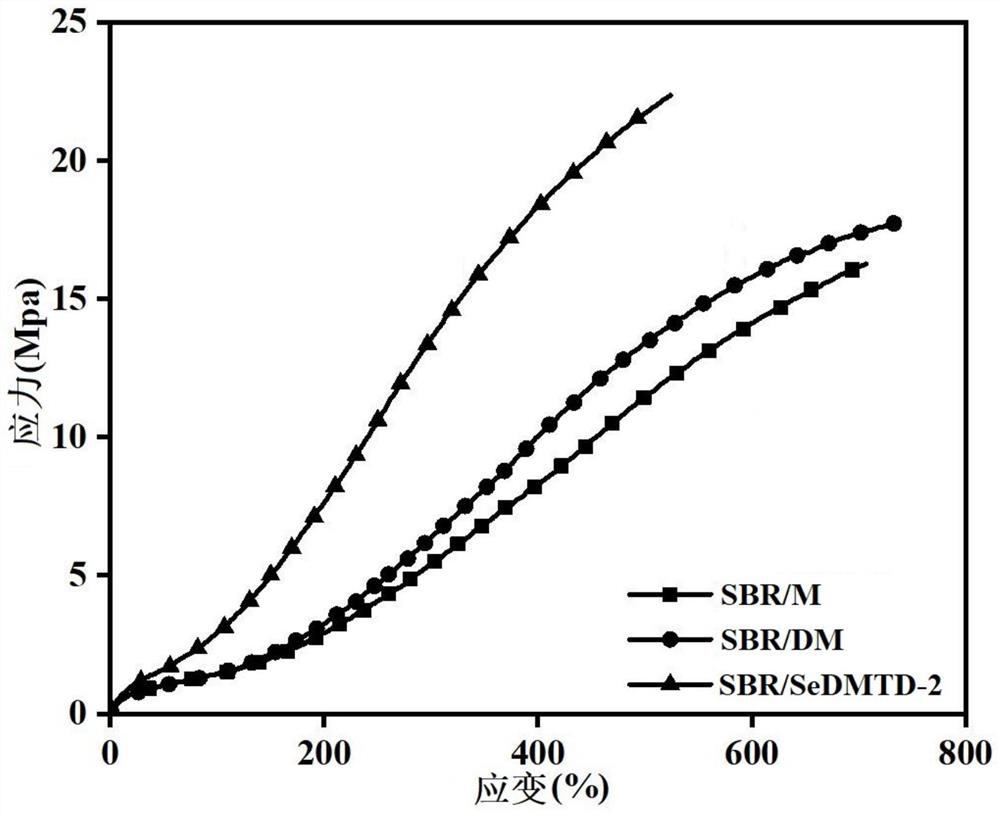

Embodiment 1

[0043] A kind of selenium coordination dimercaptothiadiazole, its preparation method comprises the following steps:

[0044] 1) Add 3.093g (0.02mol) of dimercaptothiadiazole to 100mL of ethylene glycol, control the speed of the stirrer to 400rpm, and stir at 40°C for 20min to obtain a dimercaptothiadiazole solution;

[0045] 2) Add 2.175g (0.02mol) of selenium dioxide into 50mL of absolute ethanol, control the rotation speed of the stirrer to 400rpm, and stir at 40°C for 20min to obtain a selenium dioxide solution;

[0046] 3) Slowly add the selenium dioxide solution dropwise to the dimercaptothiadiazole solution, react at 40°C for 1.5h after the dropwise addition, filter, dry, pulverize and sieve the solid product obtained by filtering to obtain the selenium complex Dimercaptothiadiazole (yield: 94.3%, melting point: 181°C, decomposition temperature: 208°C).

[0047] A kind of mixed rubber, its preparation method comprises the following steps:

[0048] With the styrene-buta...

Embodiment 2

[0050] A kind of selenium coordination dimercaptothiadiazole, its preparation method comprises the following steps:

[0051] 1) Add 4.639g (0.03mol) of dimercaptothiadiazole to 110mL of ethylene glycol, control the speed of the stirrer to 400rpm, and stir at 50°C for 20min to obtain a dimercaptothiadiazole solution;

[0052] 2) Add 2.175g (0.02mol) of selenium dioxide into 50mL of absolute ethanol, control the rotation speed of the stirrer to 400rpm, and stir at 50°C for 20min to obtain a selenium dioxide solution;

[0053] 3) Slowly add the selenium dioxide solution into the dimercaptothiadiazole solution, react at 50°C for 1.5h after the dropwise addition, filter, dry, pulverize and sieve the solid product obtained by filtration to obtain the selenium complex Dimercaptothiadiazole (yield: 93.8%, melting point: 183°C, decomposition temperature: 209°C).

[0054] A kind of mixed rubber, its preparation method comprises the following steps:

[0055] With the styrene-butadiene ...

Embodiment 3

[0057] A kind of selenium coordination dimercaptothiadiazole, its preparation method comprises the following steps:

[0058] 1) Add 6.186g (0.04mol) of dimercaptothiadiazole to 125mL of ethylene glycol, control the speed of the stirrer to 400rpm, and stir at 60°C for 20min to obtain a dimercaptothiadiazole solution;

[0059] 2) Add 2.175g (0.02mol) of selenium dioxide into 50mL of absolute ethanol, control the rotation speed of the mixer to 400rpm, and stir at 60°C for 20min to obtain a selenium dioxide solution;

[0060] 3) Slowly add the selenium dioxide solution dropwise to the dimercaptothiadiazole solution, react at 60°C for 1.5h after the dropwise addition, filter, dry, pulverize and sieve the solid product obtained by filtering to obtain the selenium complex Dimercaptothiadiazole (yield: 93.1%, melting point: 180°C, decomposition temperature: 208°C).

[0061] A kind of mixed rubber, its preparation method comprises the following steps:

[0062] With the styrene-butadien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com