Vulcanizing device and demolding method

A demoulding and vulcanization cavity technology, applied in the field of vulcanization molds and demoulding, can solve the problems of time-consuming, laborious, easy to damage, etc., and achieve the effect of good vulcanization effect and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

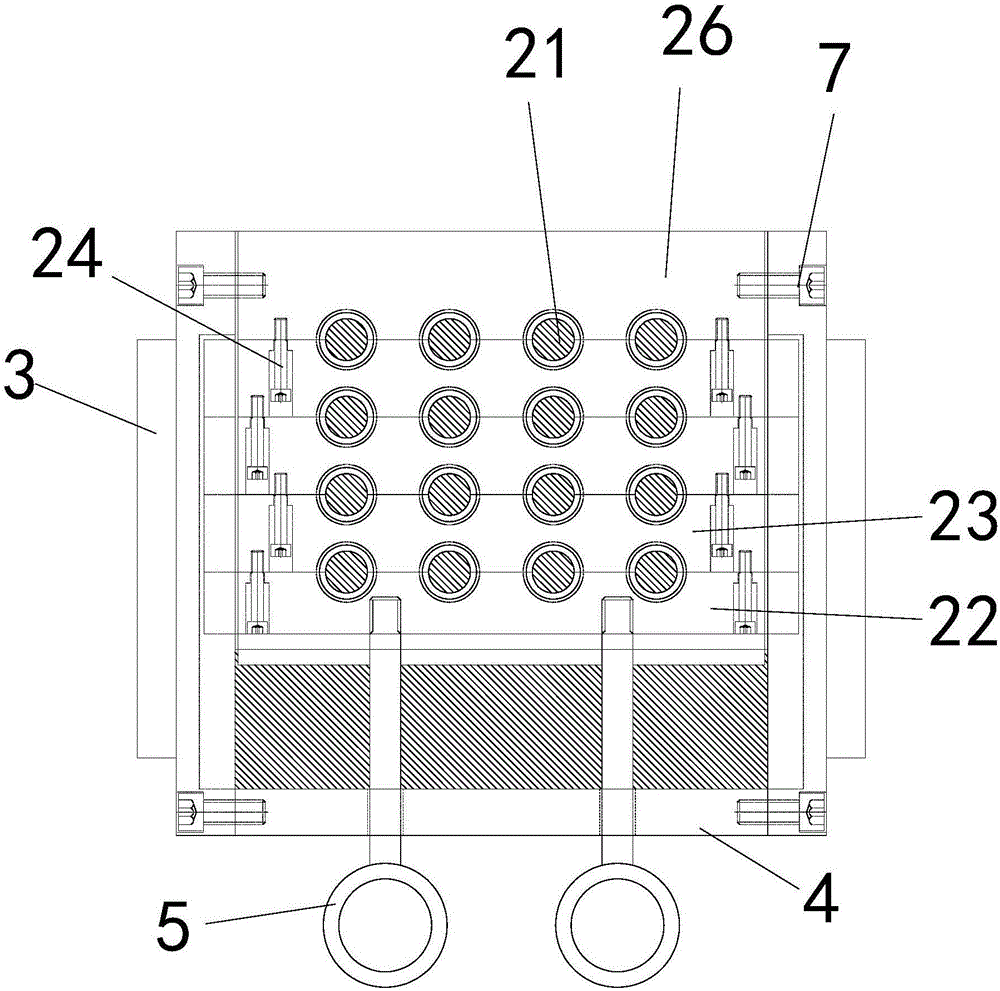

[0034] Please refer to figure 1 , a top view of the vulcanization device of the present invention, including an intermediate cavity block 2 for vulcanized products, and the intermediate cavity block 2 is arranged in the middle of the entire device for carrying metal parts that need to be vulcanized and ensuring the vulcanization process . The middle cavity movable block 2 includes several movable sliders and distance limiting elements 24 arranged between the sliders. In this specific embodiment, there are four sliders, and every two adjacent sliders There are two distance-limiting elements 24 between the blocks, and the sliders are movably connected together through the distance-limiting elements 24 to realize rapid separation after vulcanization. The whole separation process is less than 10 seconds, and the vulcanized product No damage and sticking.

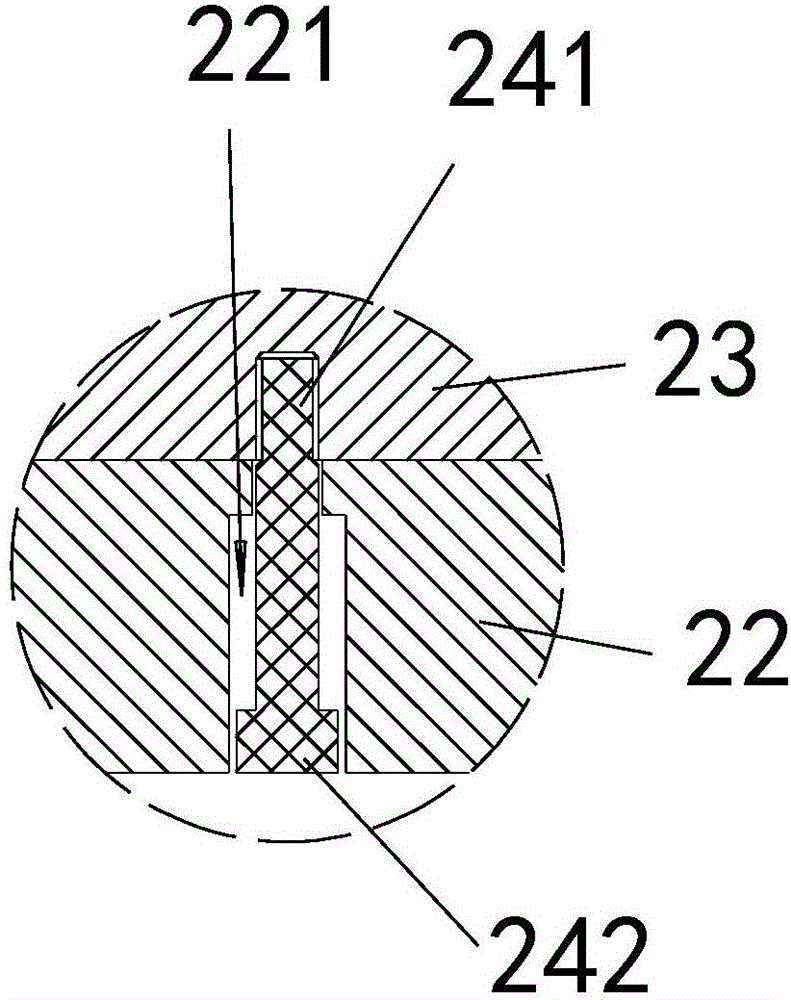

[0035] Please refer to image 3 , is a schematic structural diagram of the distance-limiting element 24 of the vulcanizatio...

specific Embodiment 2

[0042] Please refer to Image 6 , a block flow diagram of the demoulding method 8 of the present invention, using the vulcanization device, comprising the following steps:

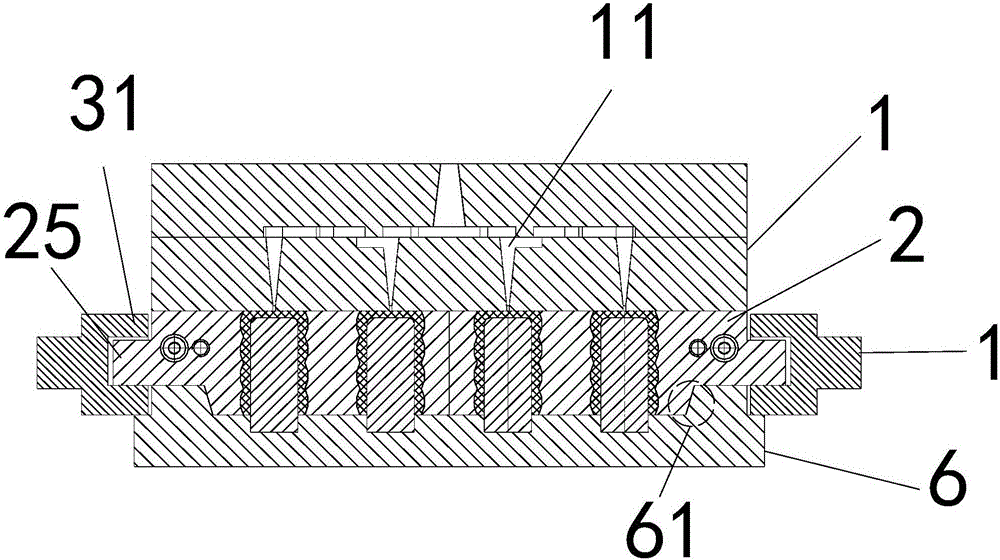

[0043] S1. After the vulcanization of the product is completed, the runner mold 1 and the support mold 6 are opened.

[0044] First, the runner mold 1 is cooled, and after cooling, it is separated from the lower intermediate cavity block 2, and the rubber in the through hole 11 is separated from the intermediate cavity block 2. After the supporting mold 6 is cooled, since the contact portion 61 is an inclined plane, it can be easily separated by directly moving downward from below. At this time, the runner mold 1 and the supporting mold 6 have been opened.

[0045] S2. Pull the push-pull rod 5 to the outside to drive the movable block 2 in the middle cavity to slide sequentially.

[0046] Further, the push-pull rod 5 pulls the first slider 22 to slide forward, and at this moment, the sliding portion 242 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com