Efficient plate vulcanizing machine body device

A technology of flat vulcanizing machine and main body, which is applied in the field of high-efficiency flat vulcanizing machine main body, can solve the problems of poor rubber product effect, and achieve the effect of simple and effective structure, convenient and fast vulcanization operation, and good vulcanization production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

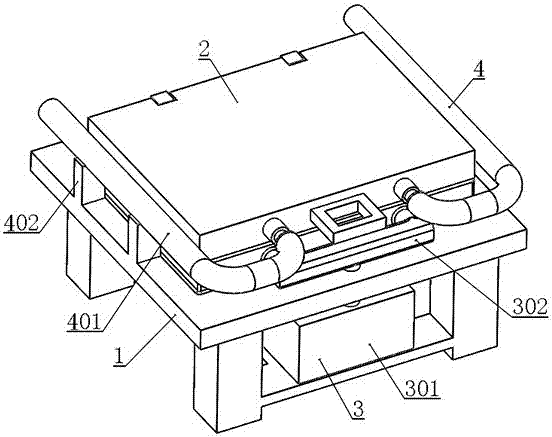

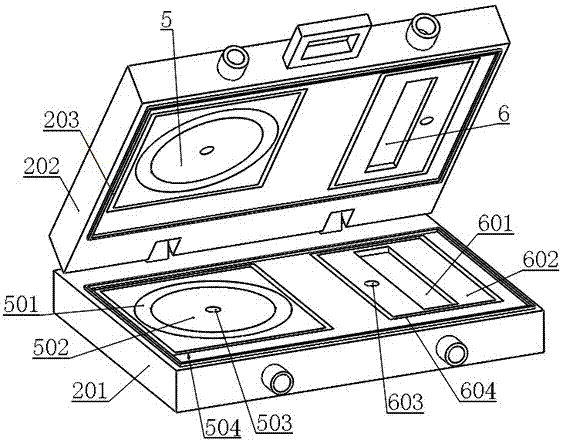

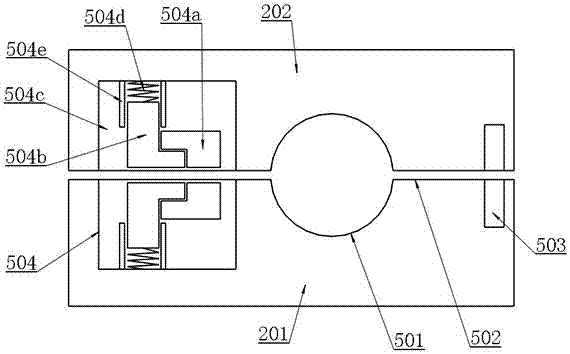

[0022] Example: as attached figure 1 , 2 , 3 and attached Figure 4 As shown, a high-efficiency plate vulcanizer main body device includes a frame 1, and a vulcanization chamber 2 arranged on the frame 1, and also includes a vulcanization chamber 2 arranged on the frame 1 and used to provide the vulcanization chamber 2 with A steam generation part 3 for vulcanization steam, and a steam discharge part 4 for discharging the vulcanization steam, the vulcanization chamber 2 includes a first vulcanization station 5 for vulcanization to make an O-ring, and a vulcanization station for vulcanization. Make the second vulcanization station 6 of rubber strip.

[0023] In this embodiment, after the vulcanization chamber 2 is closed, a preliminary closed pressure environment is provided, and the steam generating part cooperates with the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com