Bottom cover and drainage cover combined structure of drum washing machine

A drum washing machine combined with structural technology, applied to other washing machines, textiles, papermaking, washing devices, etc., can solve the problems of damage to the drain cover 31, noise, and the drain cover 31 detached from the lower cover 3, etc., and the possibility of detachment is small , reduce vibration or noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

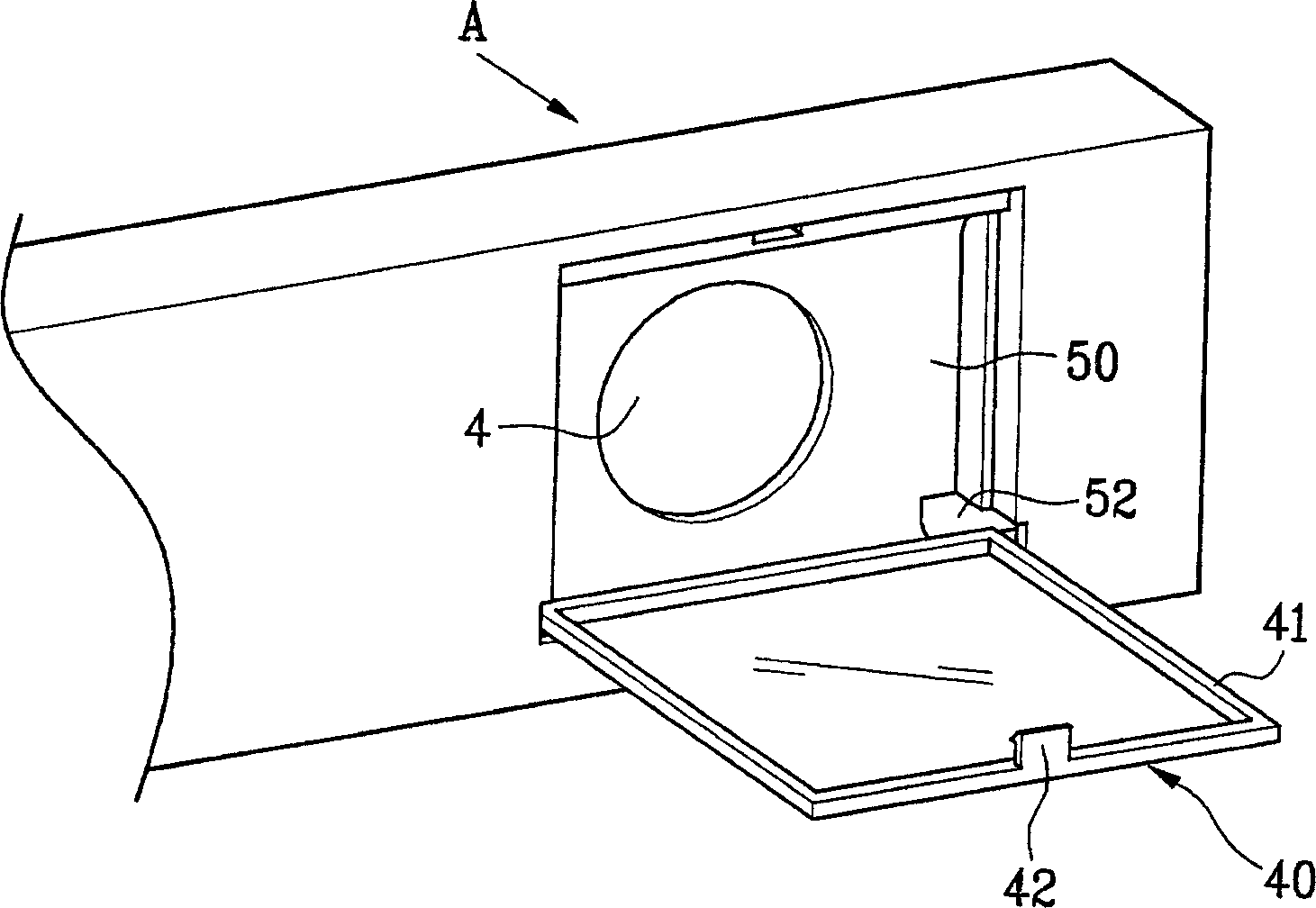

[0011] Such as image 3 As shown, the lower cover 30 of the drum washing machine provided by the present invention has a rectangular structure. As mentioned above, the lower cover 30 is installed on the lower part of the drum washing machine 1, and it has the function of protecting the lower machine base not shown in the figure. In order to lead out the drain pipe, a drain pipe hole 4 is formed on the upper side thereof. When the drain pipe hole 4 is not used, a drain cover 40 that can be opened or closed as needed is attached to cover it. A protective edge 41 is provided on the inner edge of the drain cover 40 , and a hook 42 for hanging the drain cover 40 on the lower cover 30 is provided in the upper middle of the drain cover 40 . When the drain cover 40 is pushed to one side of the lower cover 30, the hook 42 will enter the upper side of the groove 50, and be inserted into the corresponding groove to fix it. The lower end of the drain cover 40 is formed with a drain cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com