Method and device for attenuating the motion of hydraulic cylinders of mobile work machinery

A technology of engineering machinery and hydraulic cylinders, applied in the field of hydraulic cylinder movement, can solve problems such as inflow side not being fully filled, braking too late, hydraulic cylinder braking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

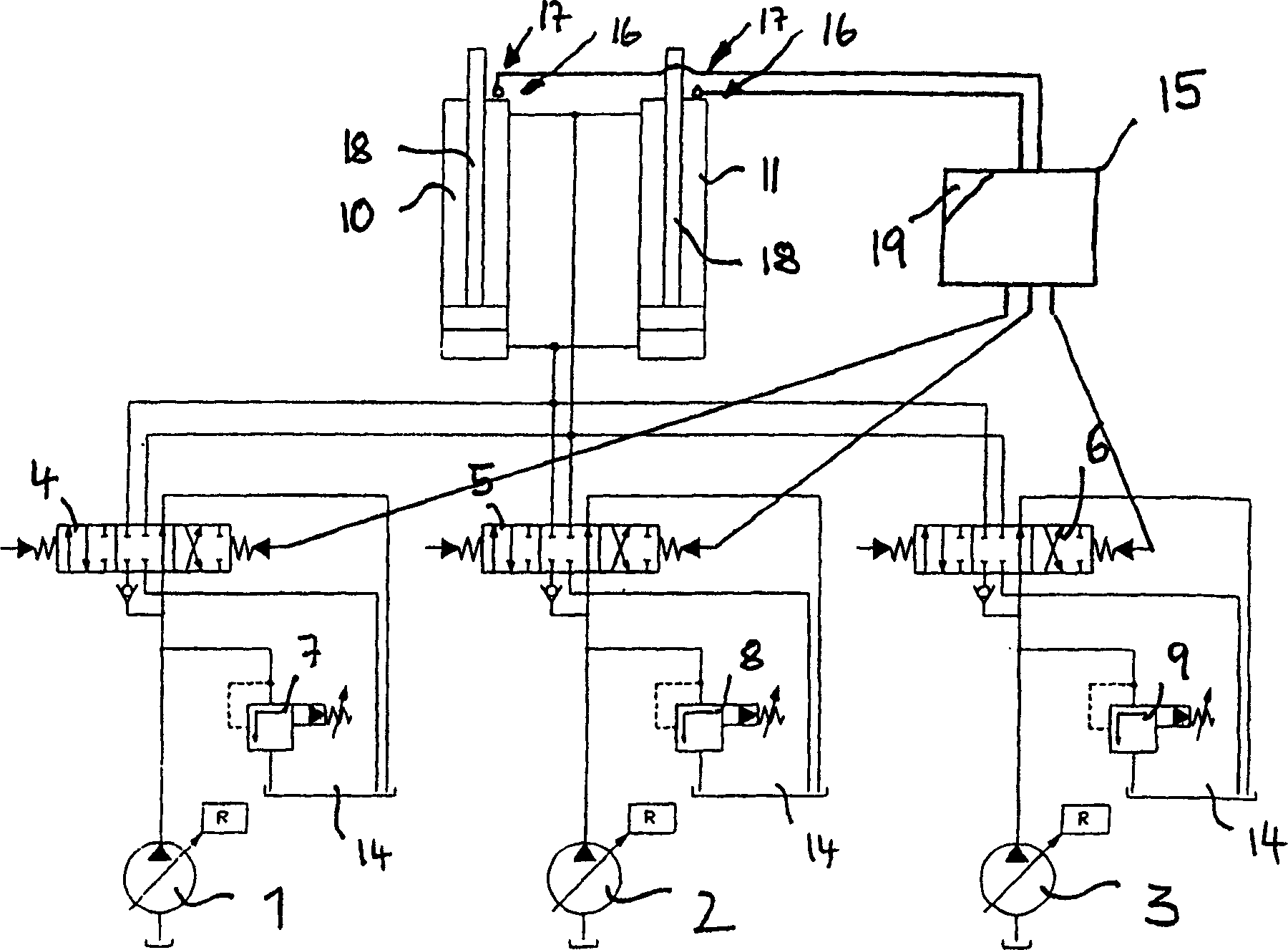

[0029] Such as figure 1 As shown, hydraulic cylinders 10 and 11 , which may be lift cylinders of a hydraulic excavator, for example, are driven by a hydraulic drive comprising three hydraulic pumps 1 , 2 and 3 , each of which can be adjusted via a regulator R. Three hydraulic pumps 1, 2 and 3 are each connected via directional control valves 4, 5 and 6 respectively to hydraulic cylinders 10 and 11, said hydraulic cylinders 10 and 11 being switched in parallel relation to each other. Via the directional control valves 4, 5 and 6, the inflows and outflows to and from the respective pumps 1, 2 and 3 of the hydraulic cylinders 10 and 11 can be cut off and closed in a manner known per se, or can be established to the pumps. A flow connection in which the direction of flow is reversible allowing the cylinder to extend and contract. Upstream of the directional control valves 4 , 5 and 6 , the pressure lines from the pumps 1 , 2 and 3 include relief valves 7 , 8 and 9 through which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com