Bend operating apparatus for endoscope

An operating device, endoscope technology, applied in the direction of endoscope, application, medical science, etc., can solve problems such as operation failure, achieve the effect of preventing wire damage and enhancing bending operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of a bending operation device for an endoscope according to the present invention will be described below with reference to the accompanying drawings.

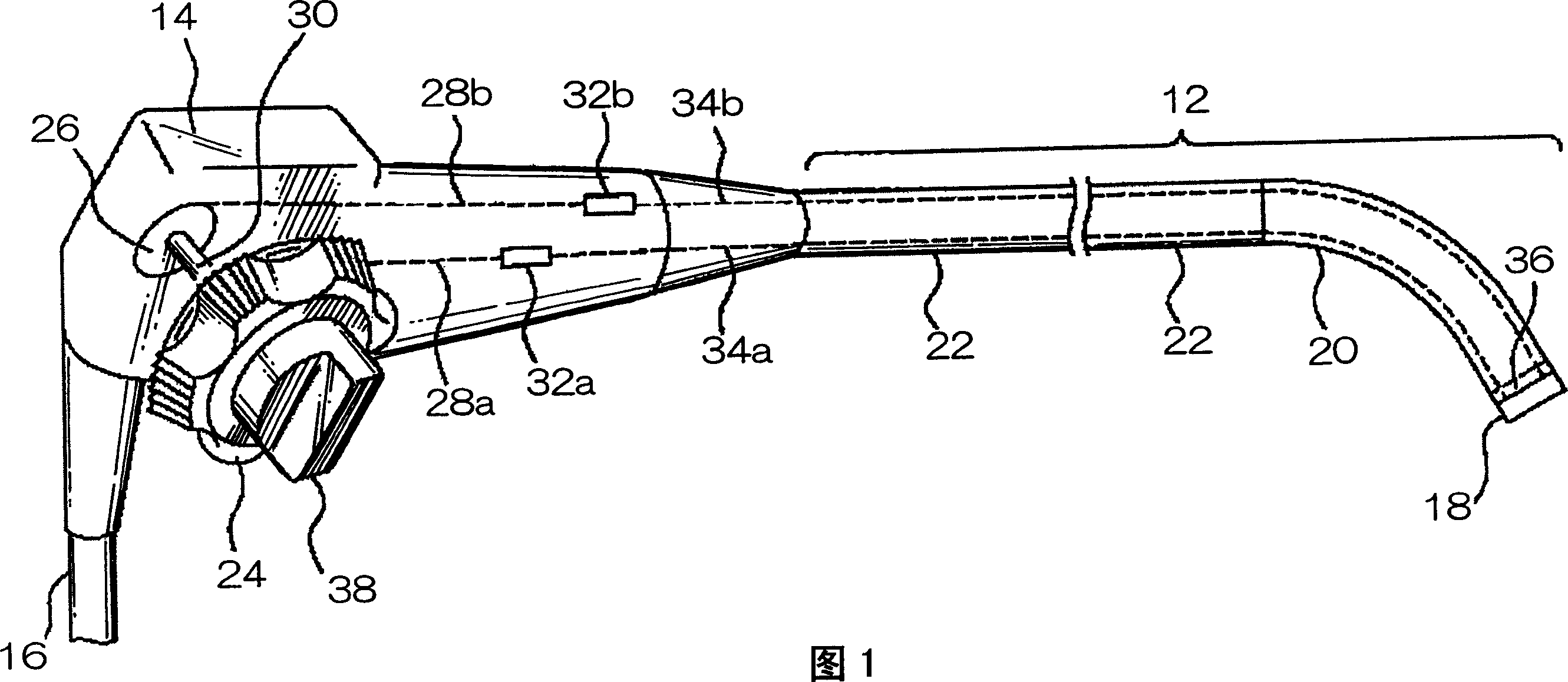

[0021] Fig. 1 is a schematic diagram of an endoscope to which a bending operation device according to the present invention is applied.

[0022] As shown in Figure 1, the endoscope mainly includes: an insertion part 12 inserted into a body cavity, a hand operation part 14 arranged at and connected to the bottom end part of the insertion part 12, and a hand operation part 14 extending from the hand operation part 14 and connected Universal cord member 16 to light source and processor (not shown in figure).

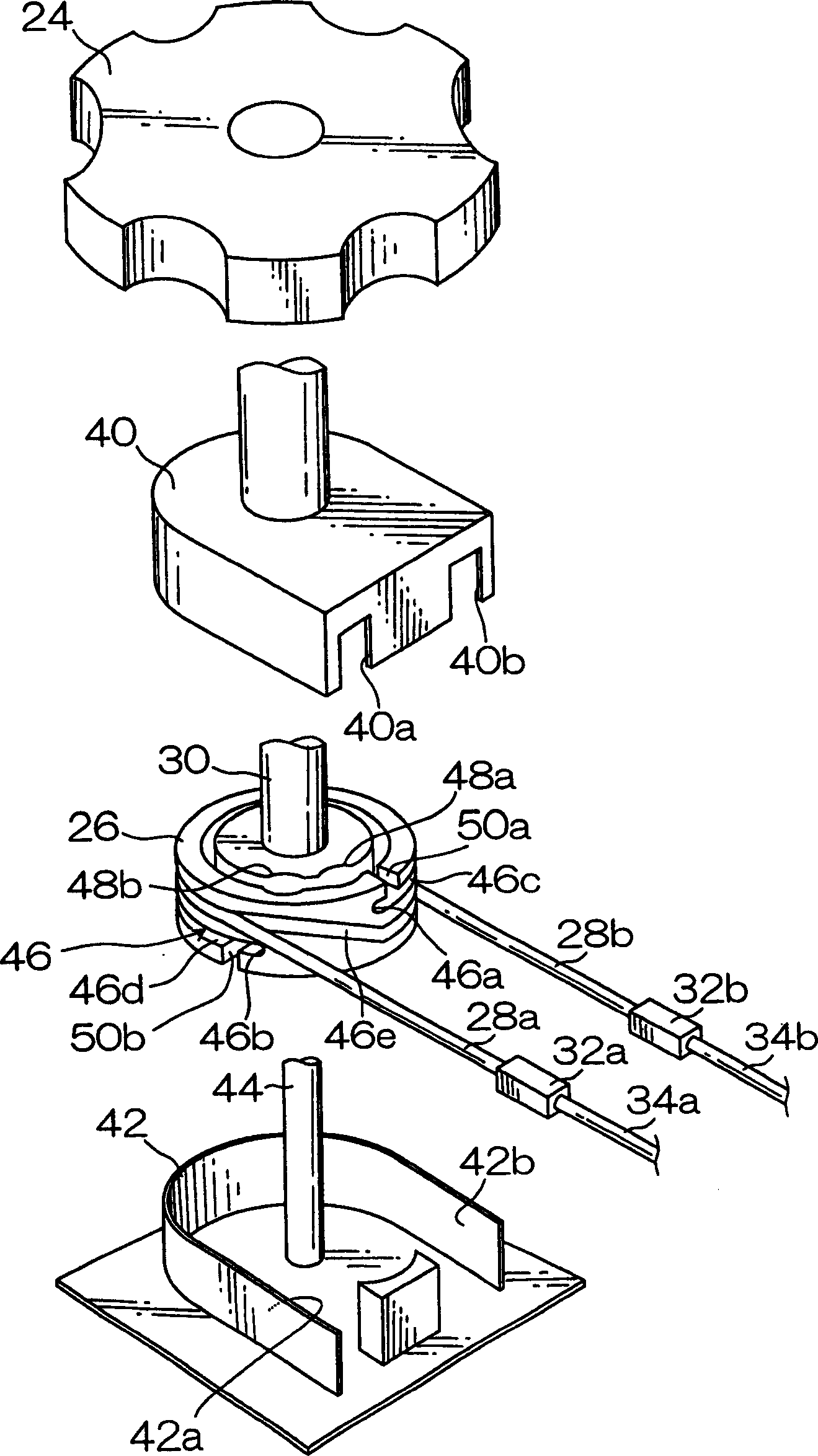

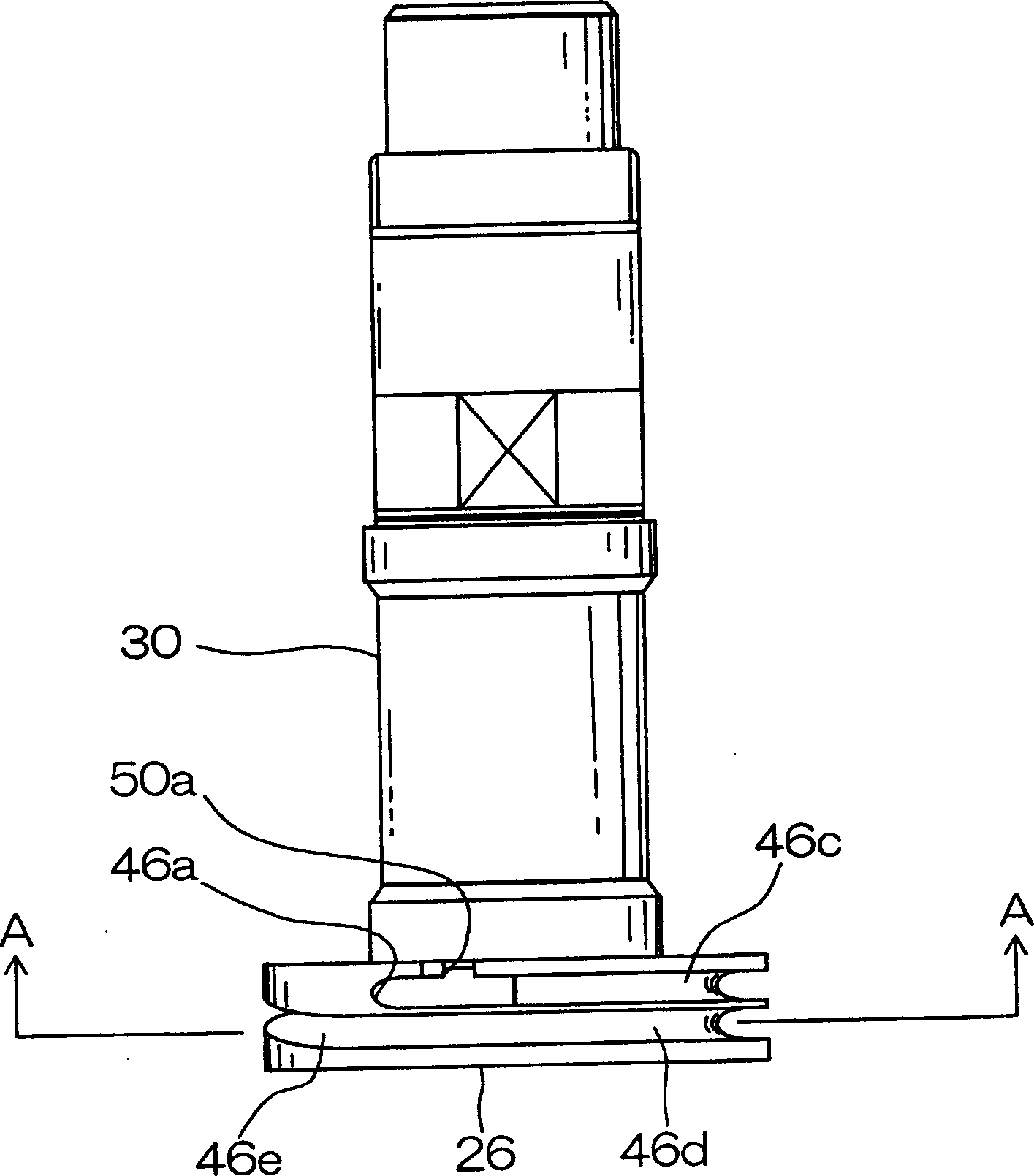

[0023] The insertion member 12 is composed of a tip portion 18, a bent portion 20, and a flexible portion 22, and the bent portion 20 is configured to be bendable at least up and down, or at least leftward and rightward. The bending portion 20 is bent by turning an angle knob 24 provided at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com