Tetrafluoroethylene composite teeth sealing gasket and method for making same

A technology of sealing gaskets and PTFE gaskets, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of poor corrosion resistance, hard surface of tooth-shaped gaskets, and low operating pressure, so as to reduce the high surface requirements Conditions, easy sealing characteristics, cold flow reduction effect

Inactive Publication Date: 2005-03-16

ZHEJIANG UNIV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The original PTFE gasket has cold flow phenomenon, and the working pressure is low, less than 5.0MPa. When the diameter of the gasket is large, it is less than 2.0MPa. The working temperature is usually below 150°C, while the toothed gasket has a hard surface and poor corrosion resistance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0018] Reactor gasket Φ900×Φ950×3, working pressure 5.0Mpa, temperature 40℃~-196℃, originally used PTFE gasket, when the pressure is 2MPa, leakage will occur, but after using metal winding gasket, the - When it is above 50°C, the seal is good, but when it is below -50°C, it will leak and metal will affect the catalyst. After switching to high-pressure PTFE composite tooth-type sealing gasket, the seal is good and has no effect on the catalyst.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

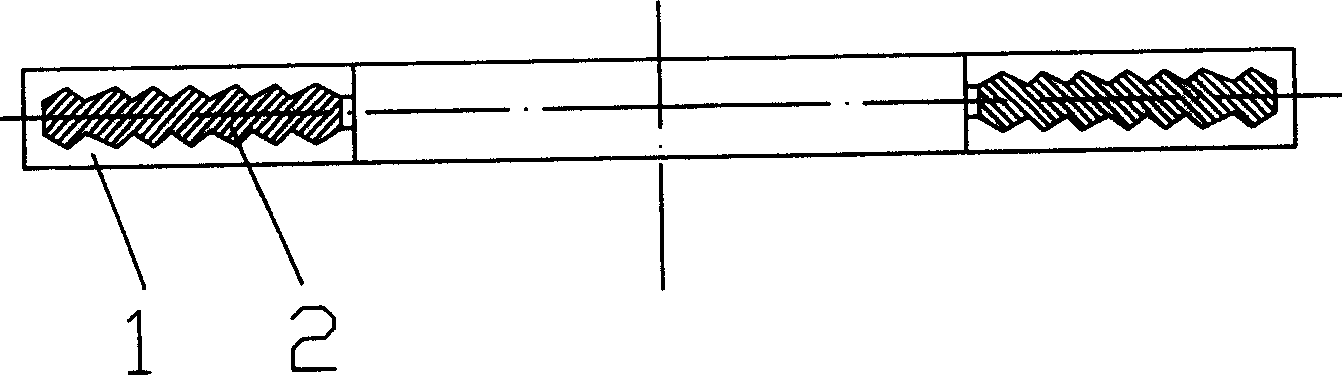

This invention discloses a tetrafluoro complex sealed shim and its facture. In the shim is embedded with the mental tooth-shaped shim, the colophony around is suppressed and sintered under the high temperature from 370 deg. C to 430 deg. C. it makes use of the high pressure of the tooth-shaped shim, the causticity of tetrafluoro and the easily sealing of the surface to reduce the cold flow of tetrafluoro and the high requirements of the surface of the shim. This invention is suitable for high pressure and strong causticity; it seals well in the cycling temperature and pressure fluctuation. It is used in the temperature from minus 210 deg. C to 250 deg. C, the pressure from 4.0 MPa to 42.0 MPa, in the fields of medical chemistry, FI chemistry, deep cooling, and oil chemistry.

Description

Technical field [0001] The invention relates to a tetrafluoro compound tooth-type sealing gasket and a manufacturing method thereof. Background technique [0002] The original PTFE gasket has cold flow phenomenon, and the working pressure is low, less than 5.0MPa. When the diameter of the gasket is large, it is less than 2.0MPa. The working temperature is usually below 150°C, and the toothed gasket has a hard surface and poor corrosion resistance. Contents of the invention [0003] The purpose of the present invention is to provide a tetrafluoro composite tooth-type sealing gasket and its manufacturing method, which can expand the application range of the tetrafluoro gasket, especially under high pressure and medium temperature conditions. [0004] The technical scheme that the present invention adopts is as follows: [0005] 1. PTFE composite tooth gasket: [0006] There are metal toothed pads embedded in the PTFE gasket. [0007] The two ends of the metal tooth pad ar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16J15/12

Inventor 邵君平汪希萱

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com