Two-step preparation method of insulation material for silver-gray aerial insulated cables

An overhead insulated cable, silver-gray technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of large gaps, achieve high insulation resistance, improve environmental stress crack resistance and heat aging resistance, and maintain The effect of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

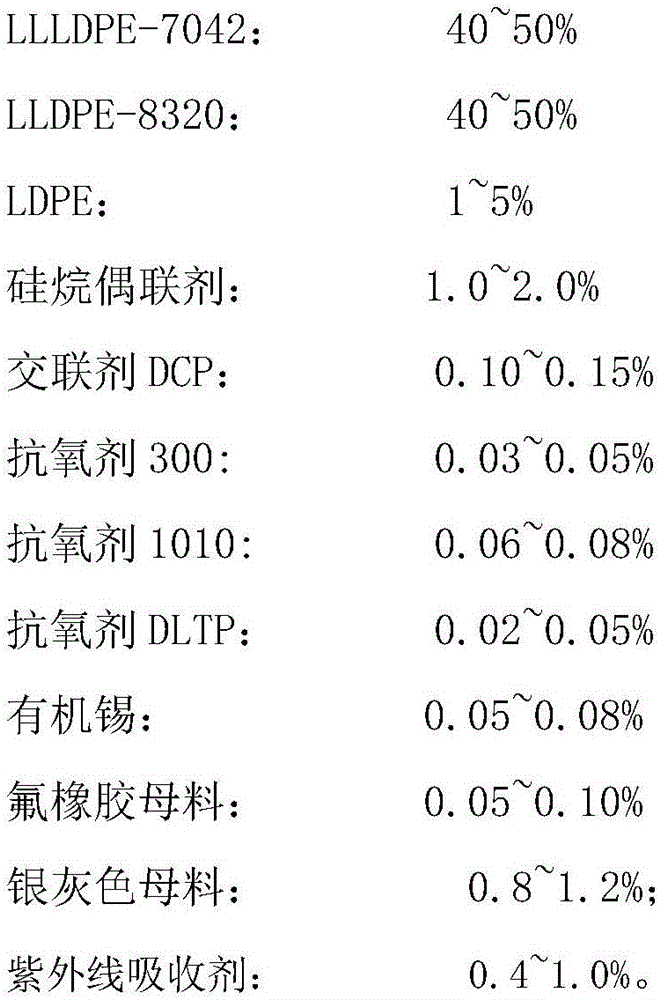

[0040] Insulation material for silver-gray overhead insulated cables, the insulation material is prepared from the following components by weight percentage:

[0041]

[0042] The two-step method for preparing insulating materials for silver-gray overhead insulated cables mainly consists of two parts, one is the preparation of catalyst masterbatch, and the other is the preparation of finished products.

[0043] 1) Preparation of catalyst masterbatch: catalyst masterbatch is LDPE, organotin, antioxidant 1010, antioxidant DLTP, fluororubber masterbatch, silver gray masterbatch and ultraviolet absorber;

[0044] Stir the above materials in the mixer, first stir at low speed for 1 minute and then at high speed for 3 minutes, then release and pour into the hopper of the extruder. After being blown dry by a fan, the pellets are cut into pellets. The pellets are dried in a drying tower at 80°C for more than 2 hours, and then packed in vacuum aluminum-plastic bags for temporary sto...

Embodiment 2

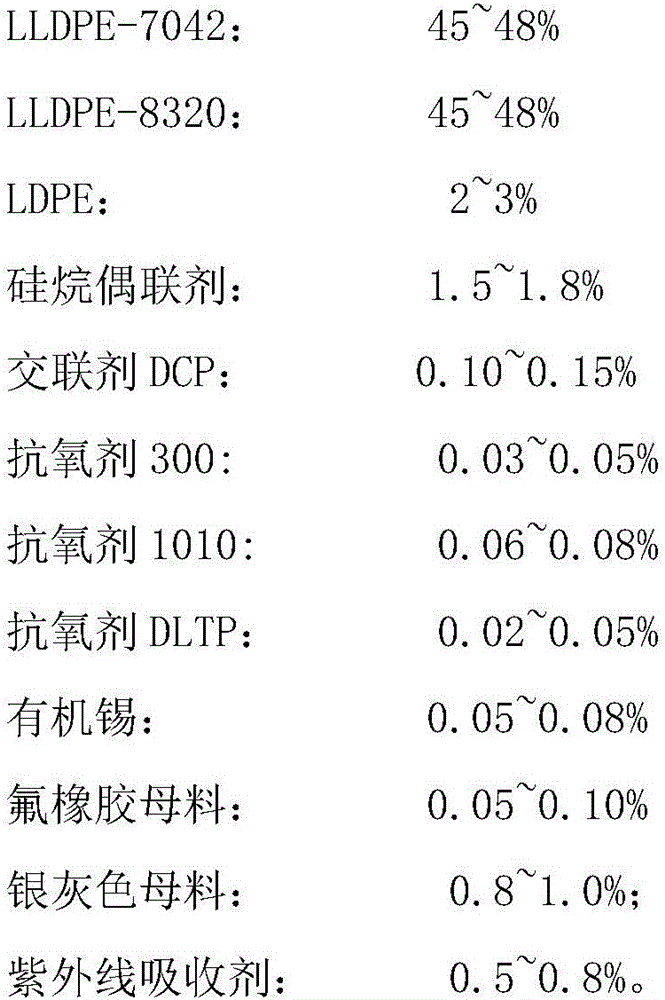

[0055] Insulation material for silver-gray overhead insulated cables, the insulation material is prepared from the following components by weight percentage:

[0056]

[0057] The insulating material mentioned above was prepared by the two-step method of Example 1.

Embodiment 3

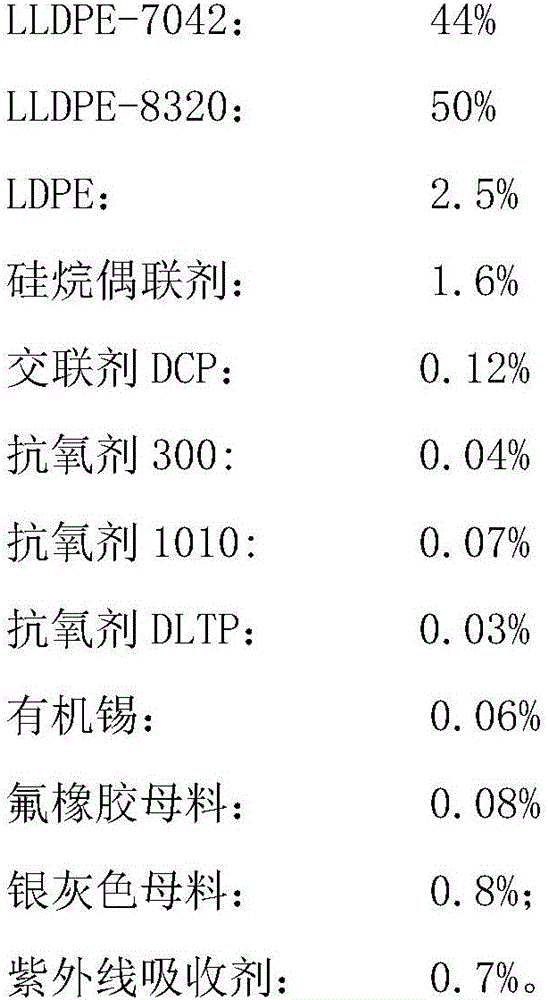

[0059] Insulation material for silver-gray overhead insulated cables, the insulation material is prepared from the following components by weight percentage:

[0060]

[0061]

[0062] The invention discloses a method for preparing an insulating material for silver-gray aerial insulated cables in one step. It mainly consists of two parts, one is the preparation of catalyst masterbatch, and the other is the preparation of finished products.

[0063] 1) Preparation of catalyst masterbatch: catalyst masterbatch is LDPE, organotin, antioxidant 1010, antioxidant DLTP, fluororubber masterbatch, silver gray masterbatch and ultraviolet absorber;

[0064] Stir the above materials in the mixer, first stir at low speed for 1 minute and then at high speed for 3 minutes, then release and pour into the hopper of the extruder. After being blown dry by a fan, the pellets are cut into pellets. The pellets are dried in a drying tower at 80°C for more than 2 hours, and then packed in vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com