Fixed bracket for accessories of cleaner

A technology for fixing racks and vacuum cleaners, which is applied in the direction of vacuum cleaners, cleaning equipment, household appliances, etc., to achieve effective management and prevent loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

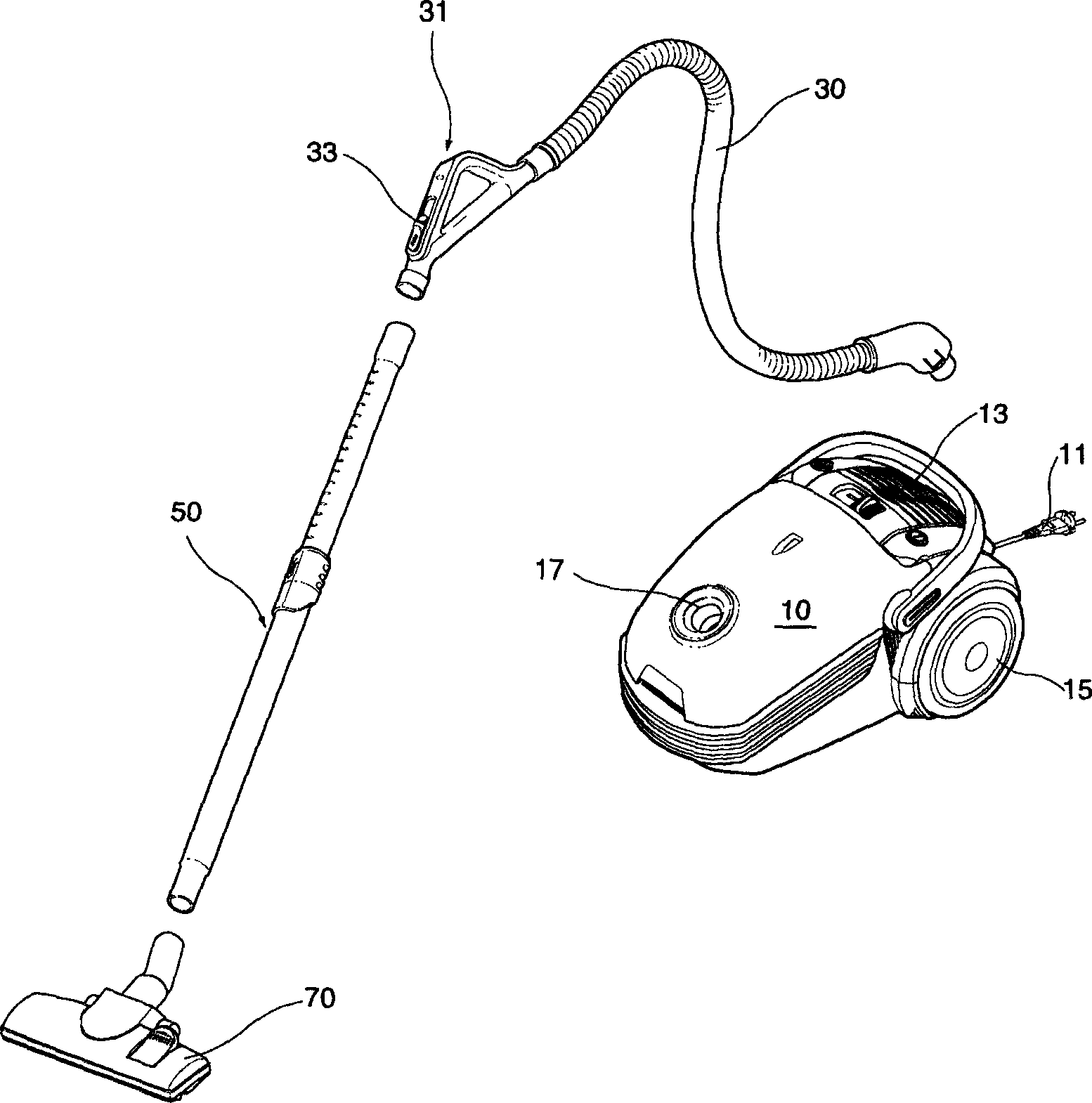

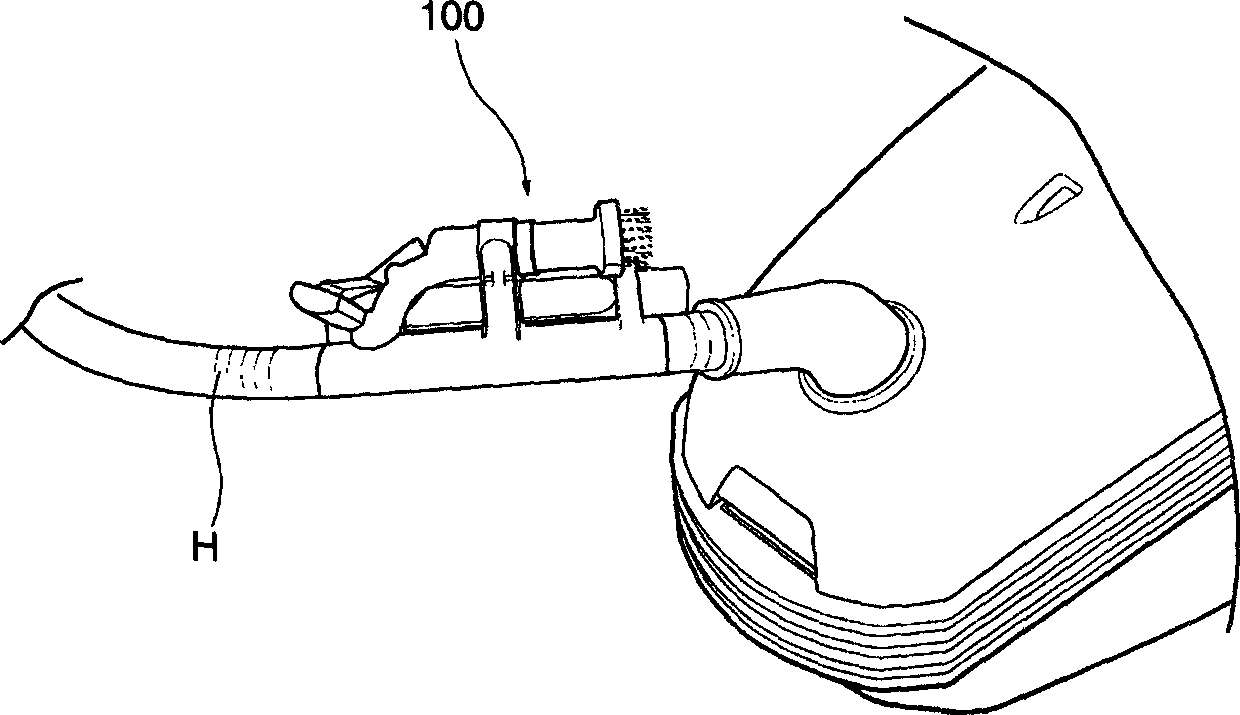

[0037] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail: figure 2 As shown, the accessory fixing frame 100 is combined on one side of the suction pipe H of the vacuum cleaner. The sub-part fixing frame 100 is a part for storing the sub-part. These accessories are a variety of accessories for cleaning places such as window frames that are difficult to clean. The accessory fixing bracket 100 is combined on the outside of the suction pipe H by utilizing the flexibility of the suction pipe H.

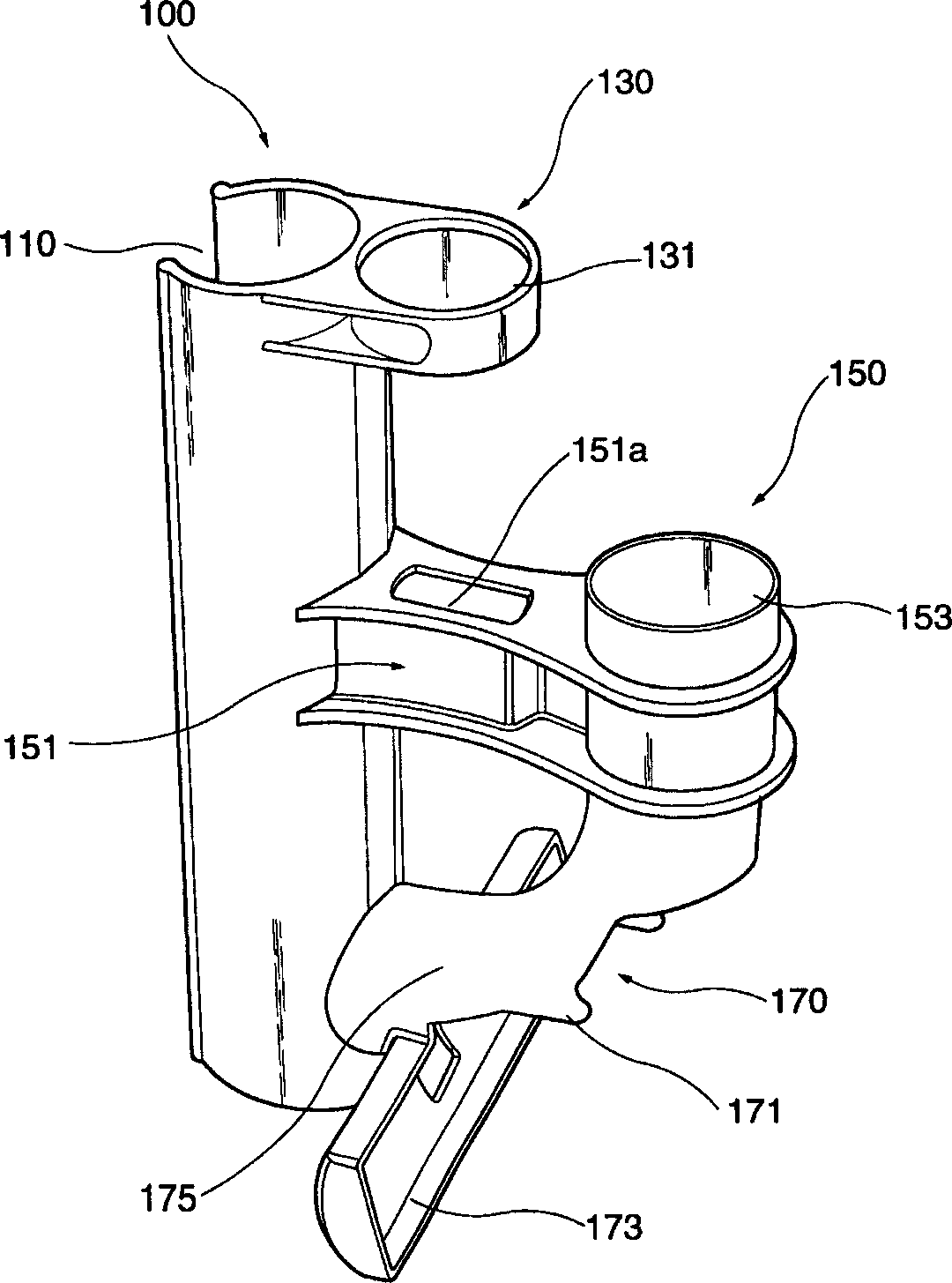

[0038] Below, refer to image 3 , the accessory fixing frame 100 under an embodiment of the present invention will be described in detail. As shown in the figure, the accessory fixing frame 100 includes an extension pipe frame 110 , a first coupling portion 130 , a second coupling portion 150 , and a third coupling portion 170 . The cylindrical extension pipe holder 110 is combined with the suction pipe H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com