Sealed touch switch and process for making same

A technology of touch switch and manufacturing process, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems that touch switches are incompetent, and achieve the effect of increasing stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings:

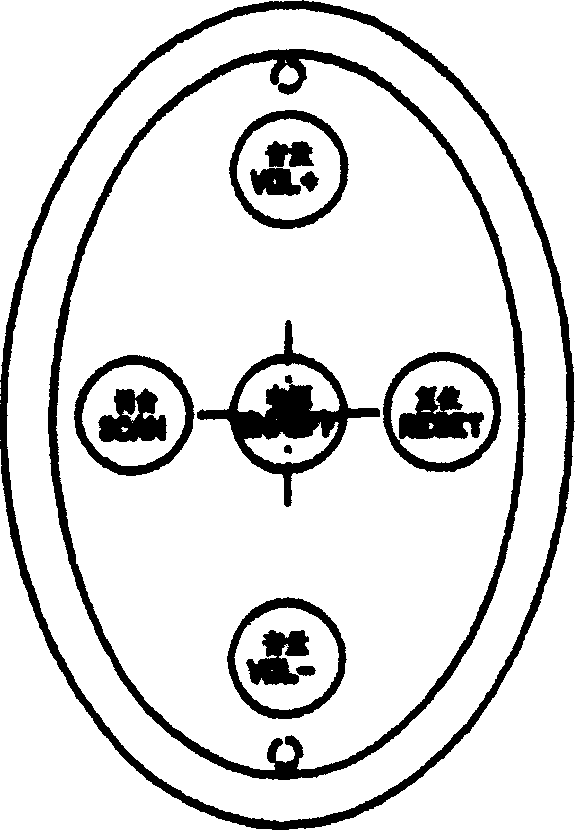

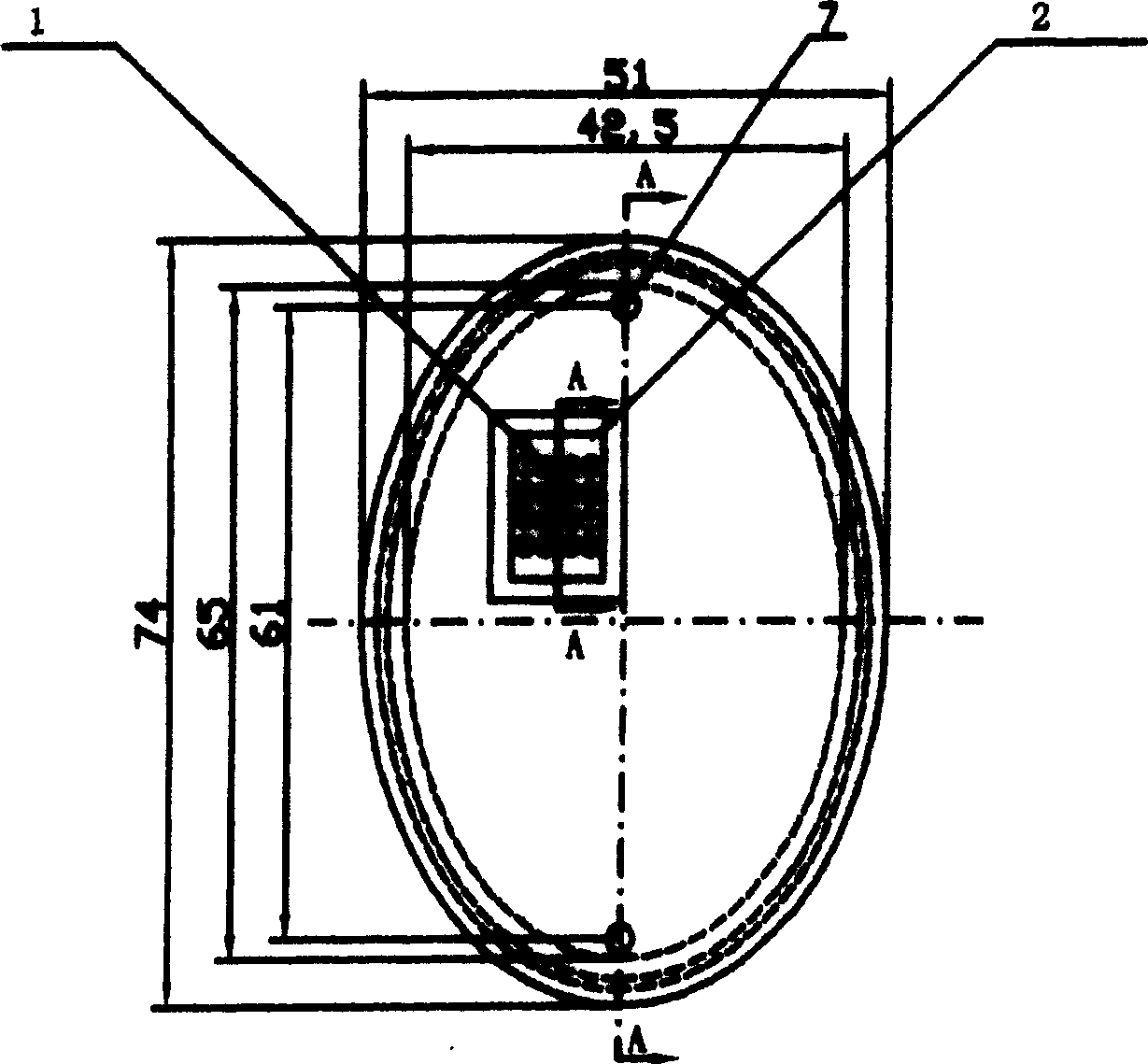

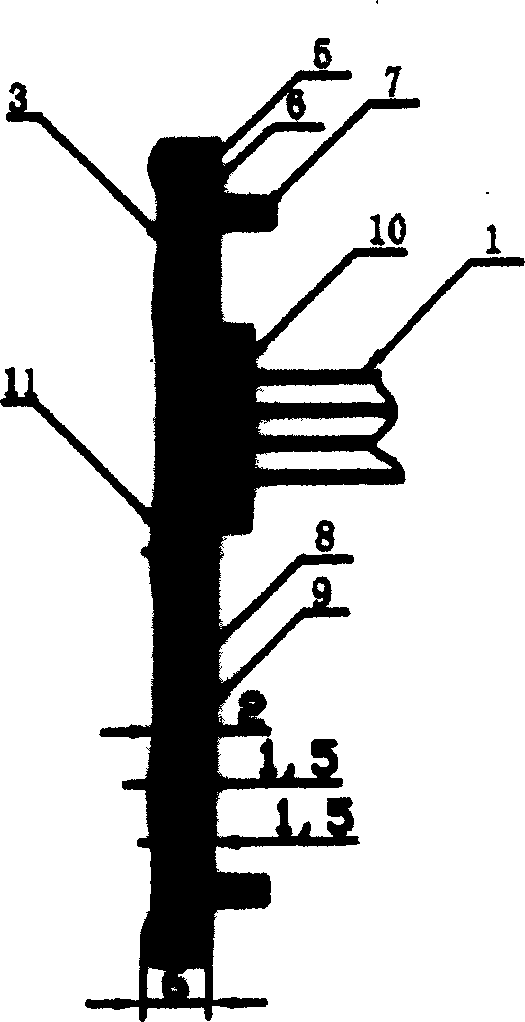

[0014] The specific embodiment of the present invention is a radio sealed touch switch used on a motorcycle. Five touch switch combinations 3 are sealed in an oval plastic box 8, and its surface layout is as follows figure 1 As shown, the power ON / OFF switch is centered, and the volume VOL+, the volume VOL-, the tuning SCAN, and the reset RESET are in sequence. figure 2 This is the bottom view of the plastic box 8 that was injection molded for the first time. The outline size is an ellipse with a major axis of 74 mm and a minor axis of 51 mm, with a lead hole 2, a screw hole 26 and a lead 1 reserved. image 3 It is a cross-sectional view of the sealed touch switch AA. The touch switch assembly 3 is sealed in the plastic box 8, the fixing screw 7 is exposed outside, the gasket 5 and the nut 6 are sealed in the plastic box 8, the lead 1 is led out by the lead hole 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com