Electro-pyrotechnic initiator

A technology for detonators and pyrotechnics, which is used in blasting cartridges, weapon accessories, offensive equipment, etc., and can solve problems such as loose internal joints, expensive detonators, and air tightness problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

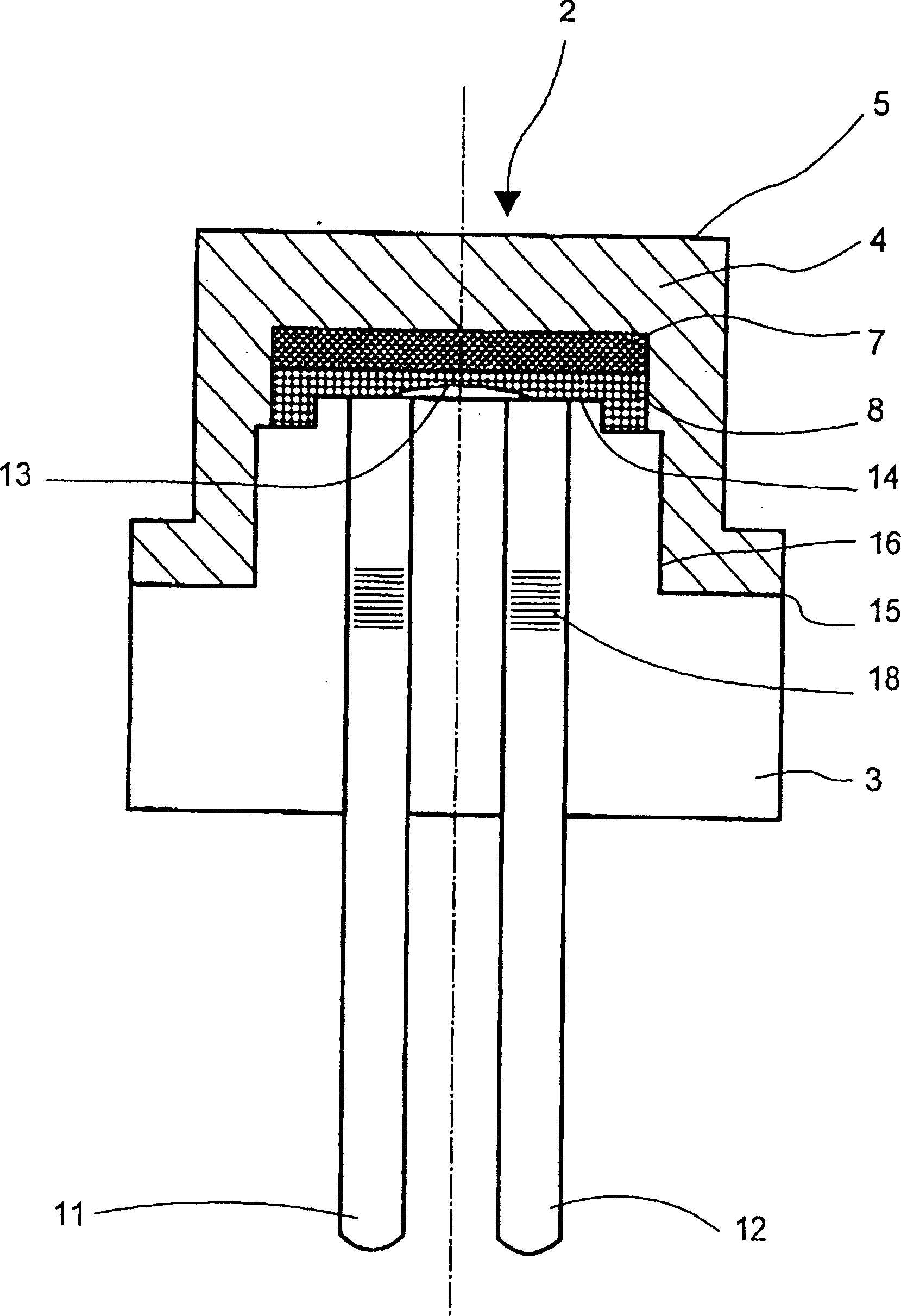

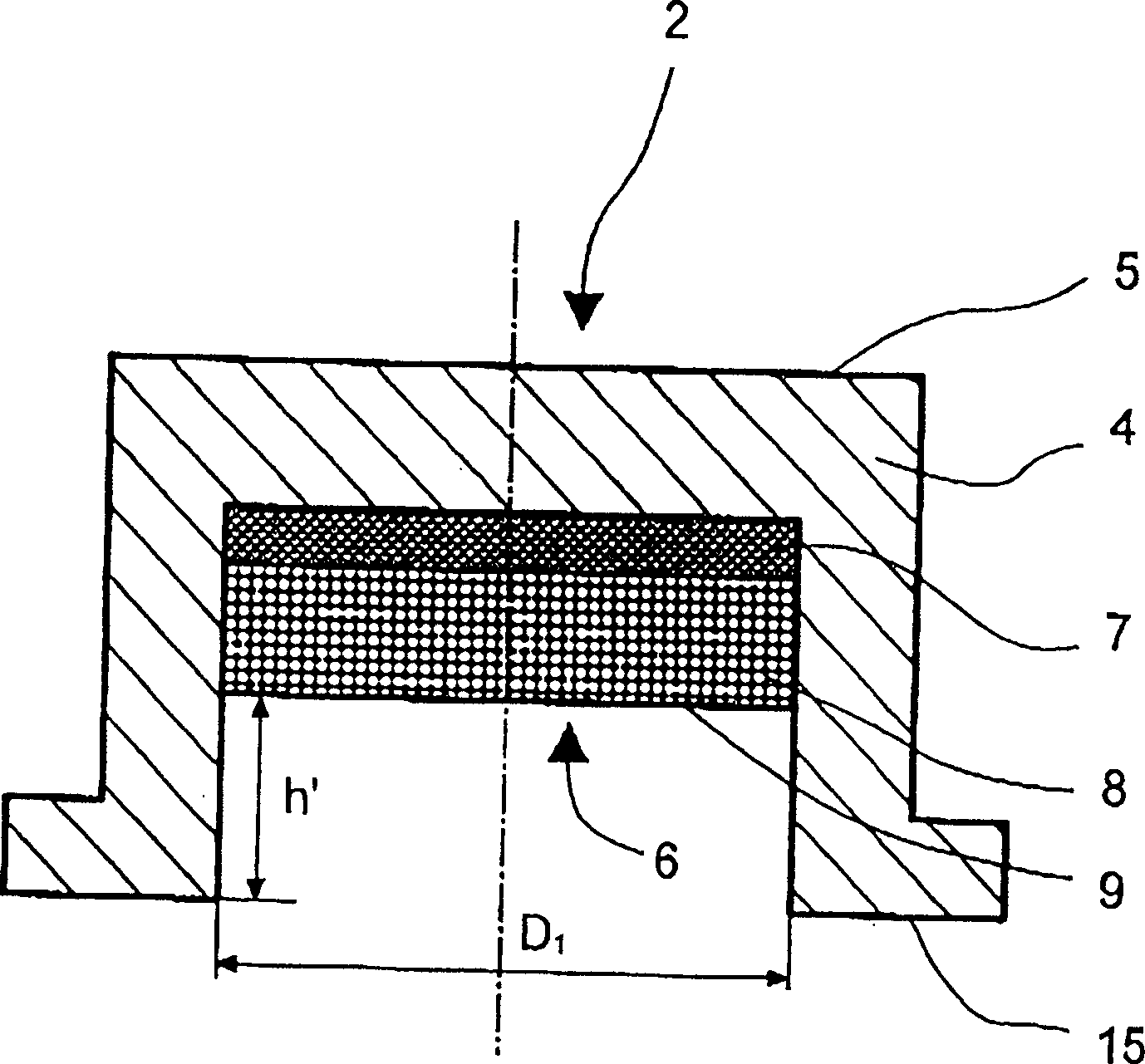

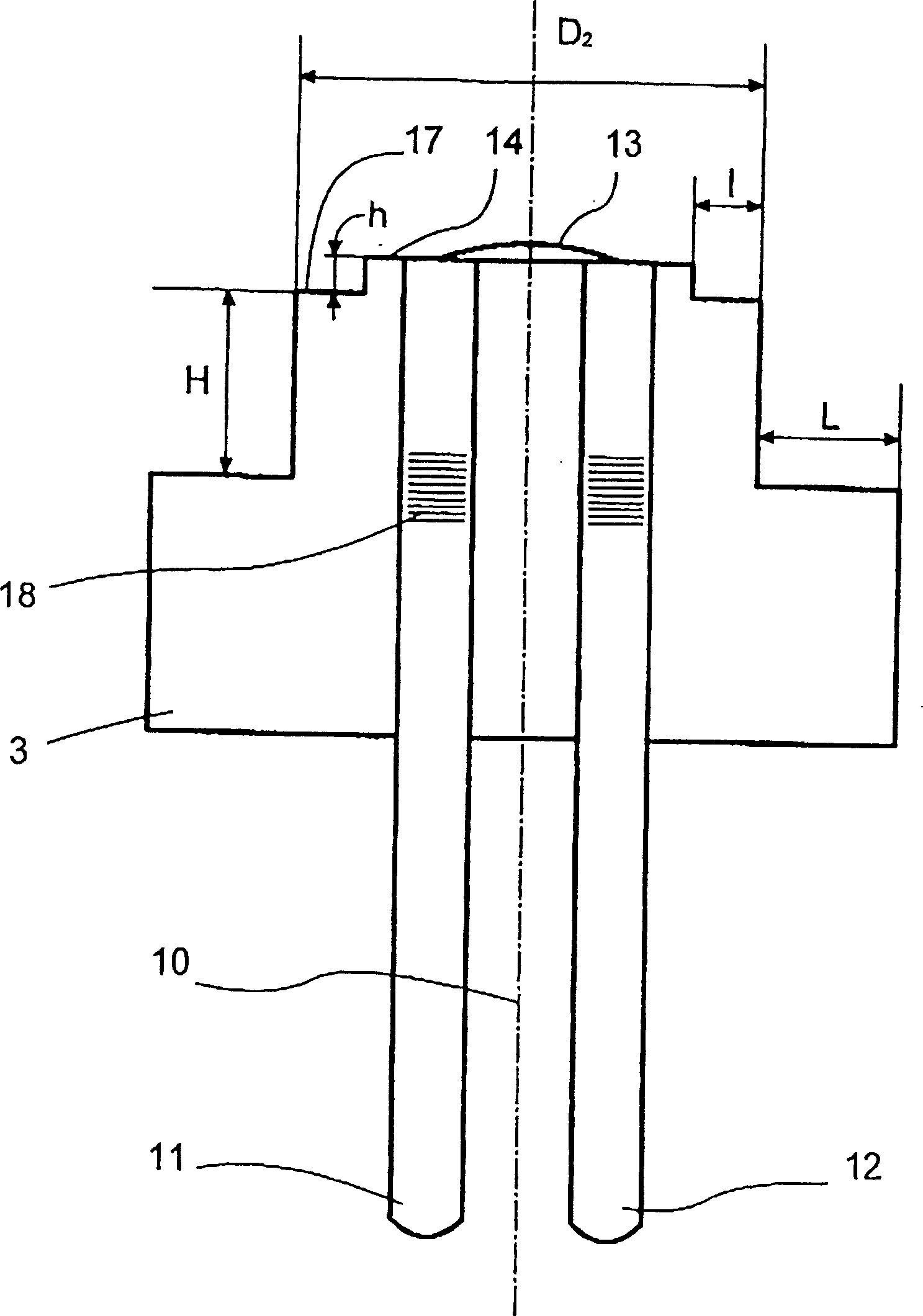

[0034] The electric pyrotechnic initiator of the present invention includes a casing 1 , and the casing 1 includes a first part 2 and a second part 3 . The first part 2 comprises a plastic wall 4 integral with a bottom 5 also made of plastic, the first part 2 being a single piece. This first part 2 is called a container. The container 2 is filled with a pyrotechnic charge 6 by a dry loading process. The pyrotechnic charge 6 comprises at least one chemical compound. In one embodiment, the container 2 contains a first compound 7 called an additional compound and a second compound 8 called a main compound. Each compound of the pyrotechnic charge 6 is loaded in bulk and pre-compacted. Advantageously, the pre-compaction pressure of the main compound 8 is less than 120 bar and the pre-compaction pressure of the additional compound 7 is greater than 150 bar. The final compressive stress occurs when the first part 2 is hermetically fitted together with the second part 3 comprising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com