Clothes shape sheet making method

A technology of line segment and size, which is applied in the field of plate making for making top models, can solve the problems of not getting rid of it, not solving the problems of conformity between the human body and clothing, and the difficulty of line segment size, etc., and achieves the effect that the method is easy to learn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0032] Unit: points

[0033]

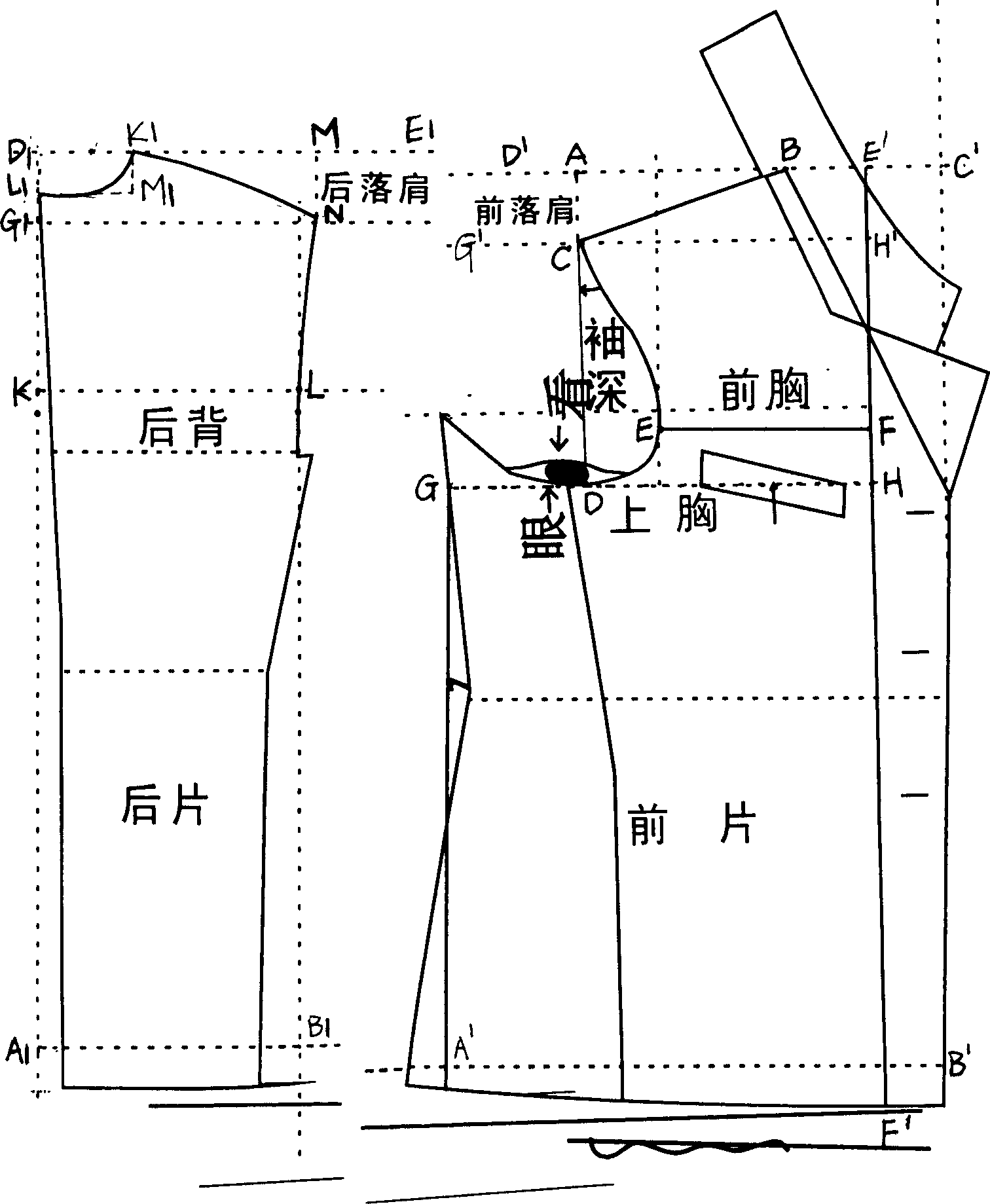

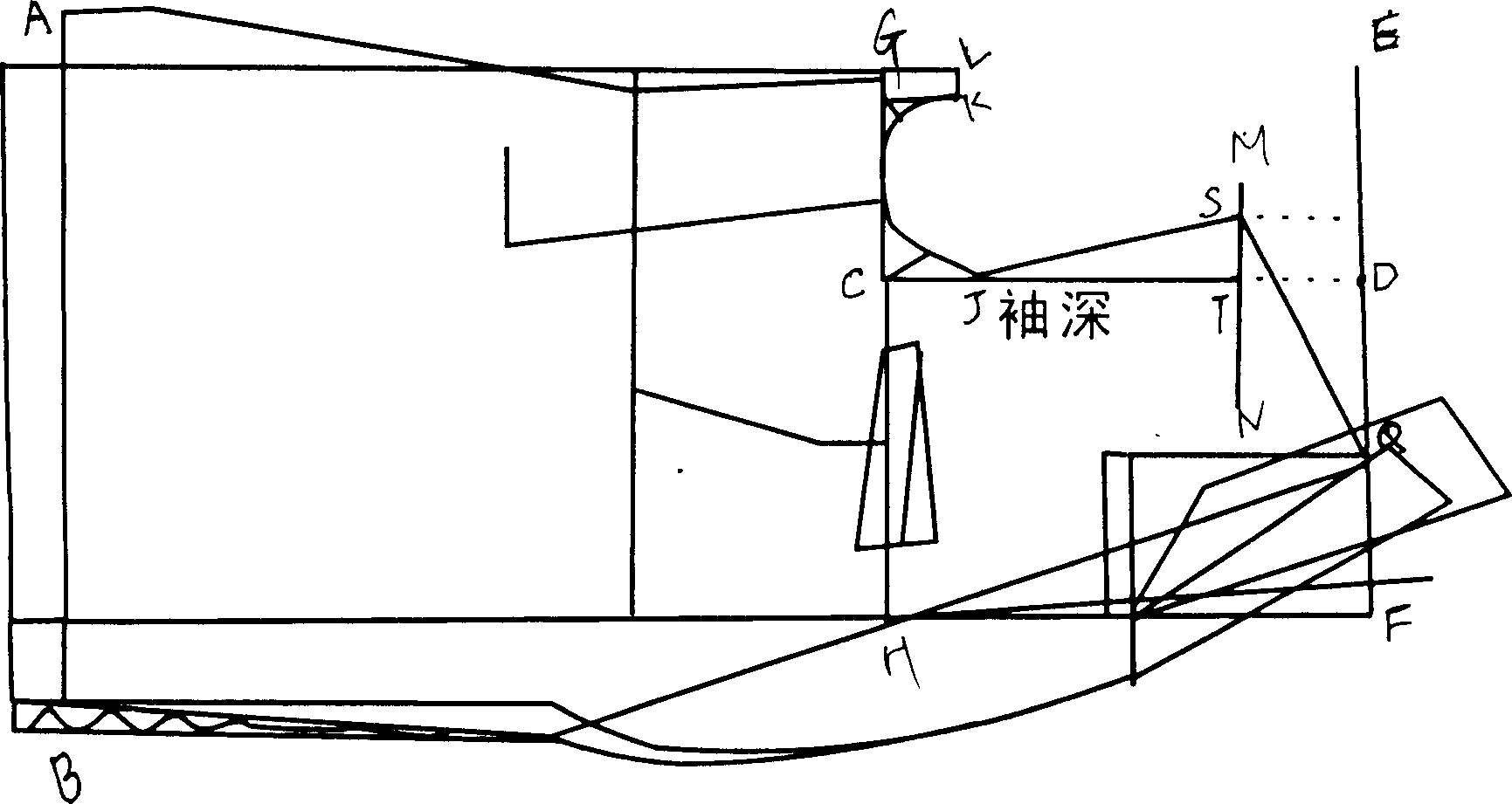

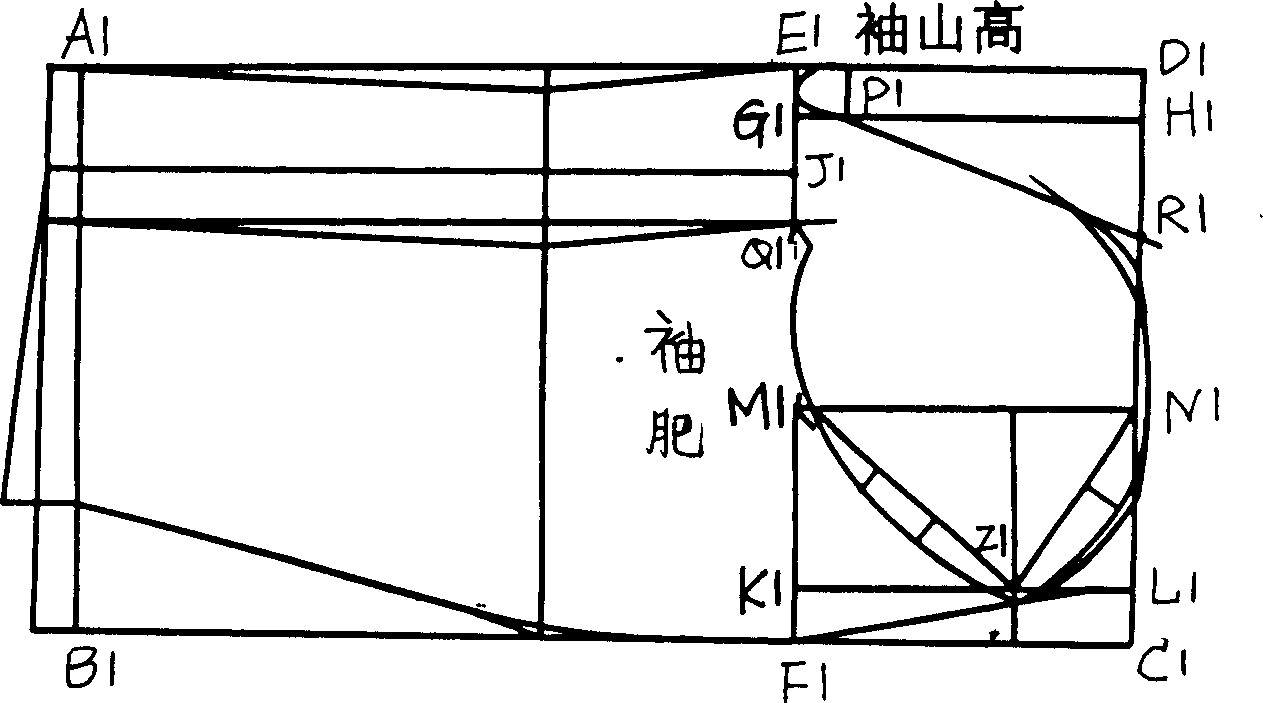

[0034] Referring to embodiment 1, the sequence of three opening clothes type is:

[0035] 51 ±2 61 ±2 16 ±0.5 13 ±0.5 101 ±3

[0036] The bust is indicated by X, when X±10 points, the sleeve depth is based on 72 -2.5 +1.5 ;

[0037] When X±10 points, the front chest is ±2 on the basis of 51;

[0038] When X±10 points, the back is ±2 on the basis of 61;

[0039] When X±10 points, the front drop shoulder is ±0.5 on the basis of 16;

[0040] When X±10 points, the back shoulder is ±0.5 on the basis of 13;

[0041] When X±10 points, the upper chest is ±3 on the basis of 101.

Embodiment 13-26

[0043] Unit: points

[0044]

Embodiment 27-36

[0046] Unit: points

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com