Mounting structure of bumper beam

A technology for installing structures and bumpers, applied in the directions of bumpers, transportation and packaging, vehicle safety arrangements, etc., can solve the problem of low weight and high strength of bumper beams, insufficient absorption of impact energy, and reduced bending strength of bumper beams, etc. problems, to achieve the effect of convenient vertical positioning, stable energy absorption, and prevention of vertical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

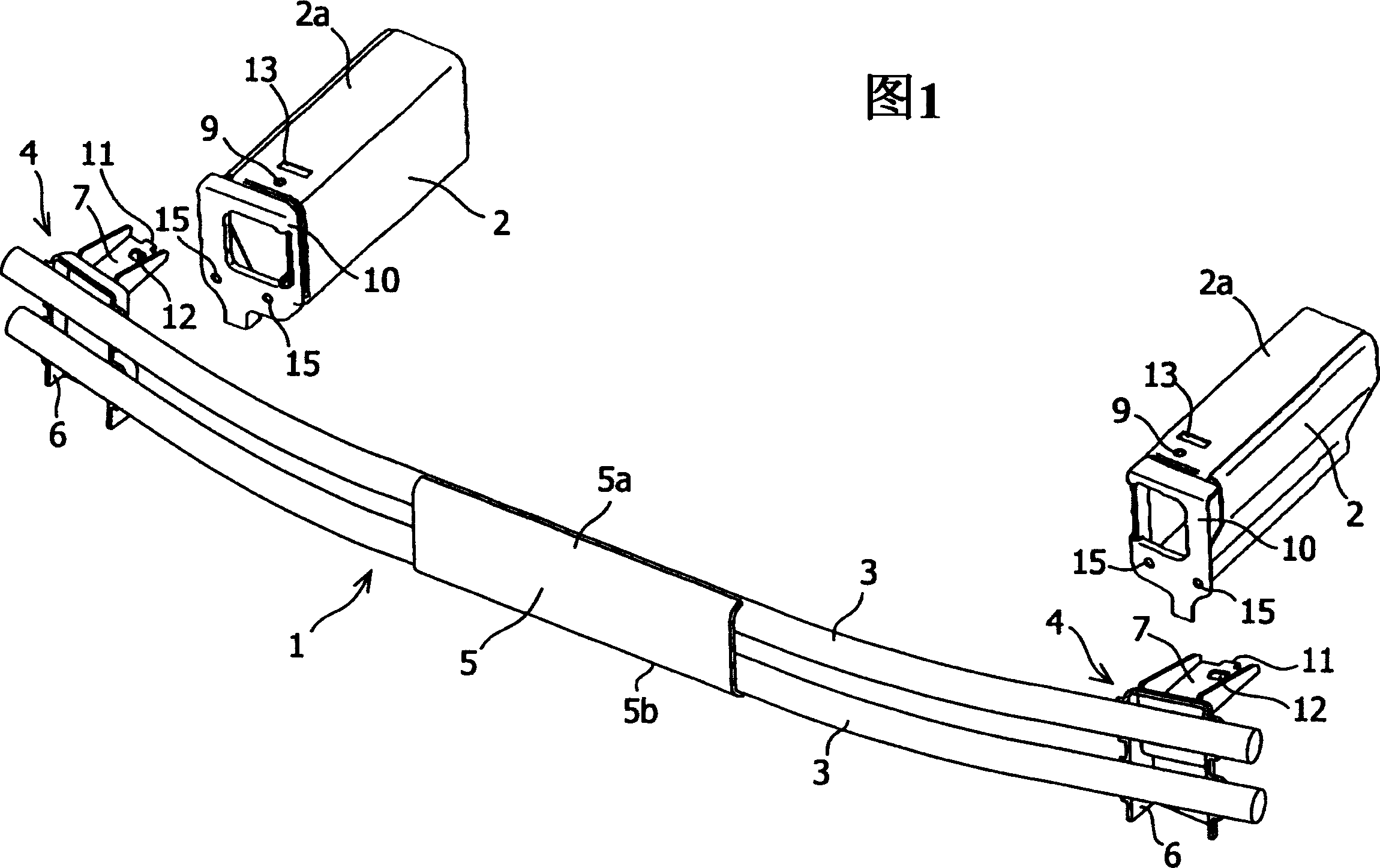

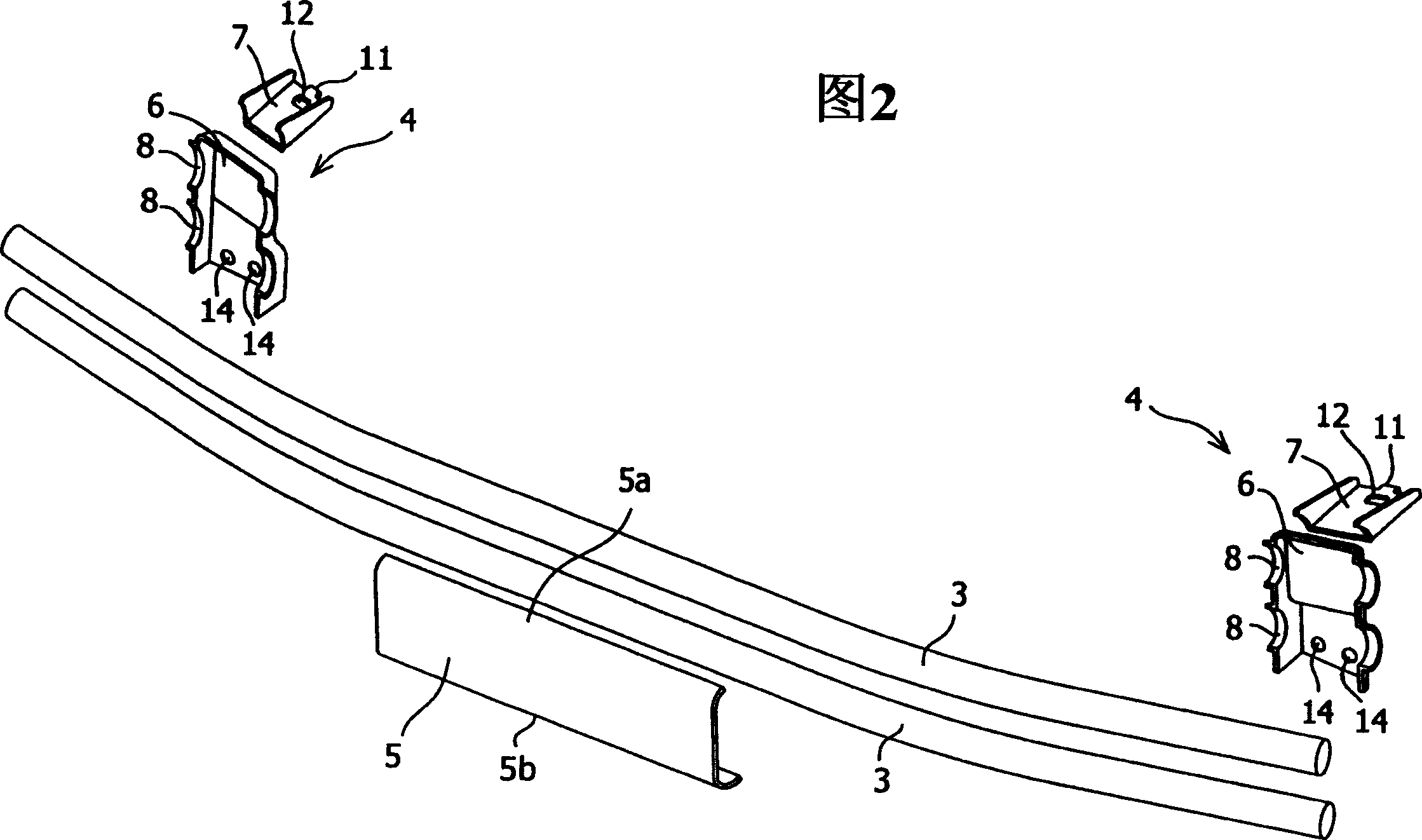

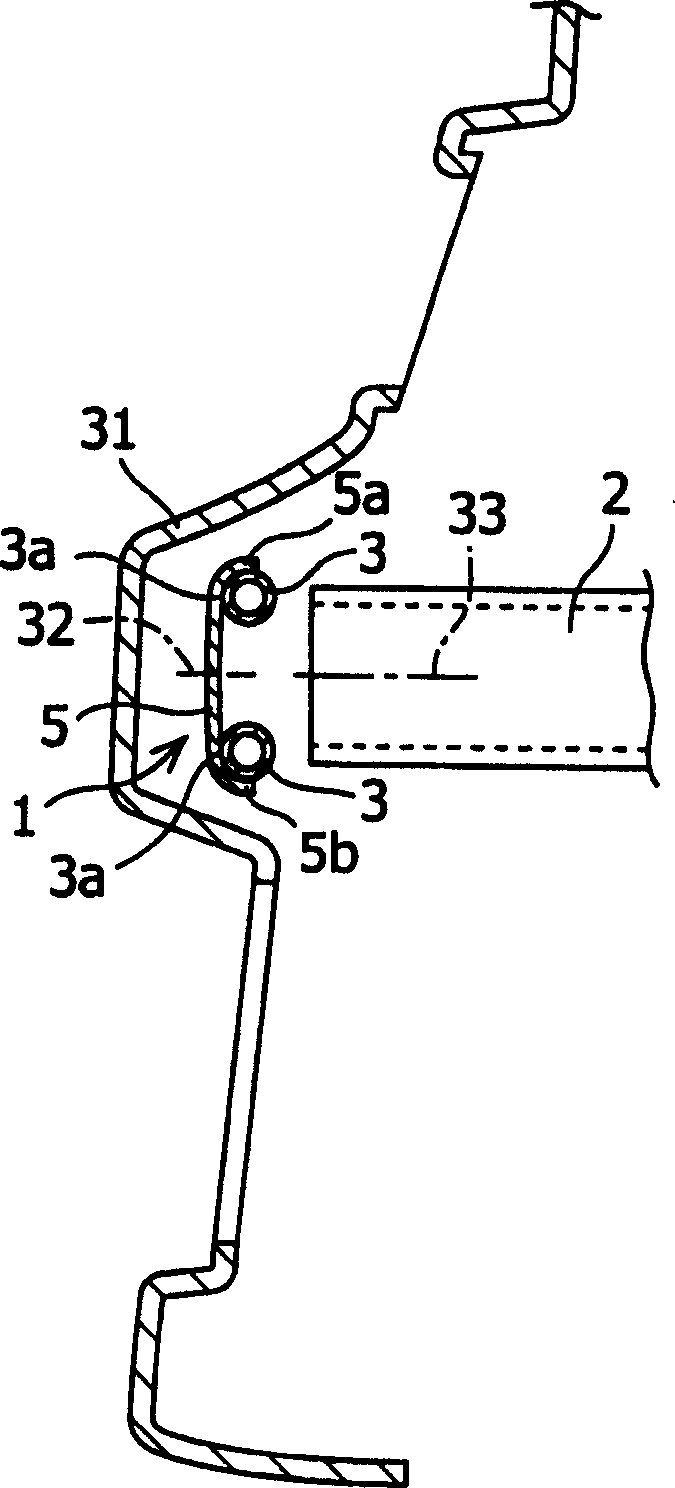

[0031] The following will combine Figure 1 to image 3 The best mode for carrying out the present invention will be described in detail. FIG. 1 is a perspective view of a bumper beam 1 before being mounted to a side member 2, and FIG. 2 is an exploded perspective view of the bumper beam 1 disassembled into individual components. image 3 is a sectional view of the bumper beam 1 mounted on the side member 2, where it is cut from the center portion in the vehicle width direction.

[0032] In this embodiment, the description is made for the case where the bumper beam 1 is composed of two tubes. Meanwhile, in the present embodiment, the description is made corresponding to a bumper beam mounting structure in which the bumper beam 1 is mounted on a lower portion in front of the vehicle.

[0033] In the bumper beam mounting structure shown in FIG. 1 , the bumper beam 1 is mounted on the side beam 2 on the side of the vehicle body. As shown in FIGS. 1 and 2, the bumper beam 1 has tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com