Objective nuclear scale calibrating system and its automatic calibration method

The technology of a calibration system and calibration method, which is applied in the field of nuclear scale physical calibration system, can solve the problems such as the large influence on the measurement accuracy of nuclear scales, and achieve the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

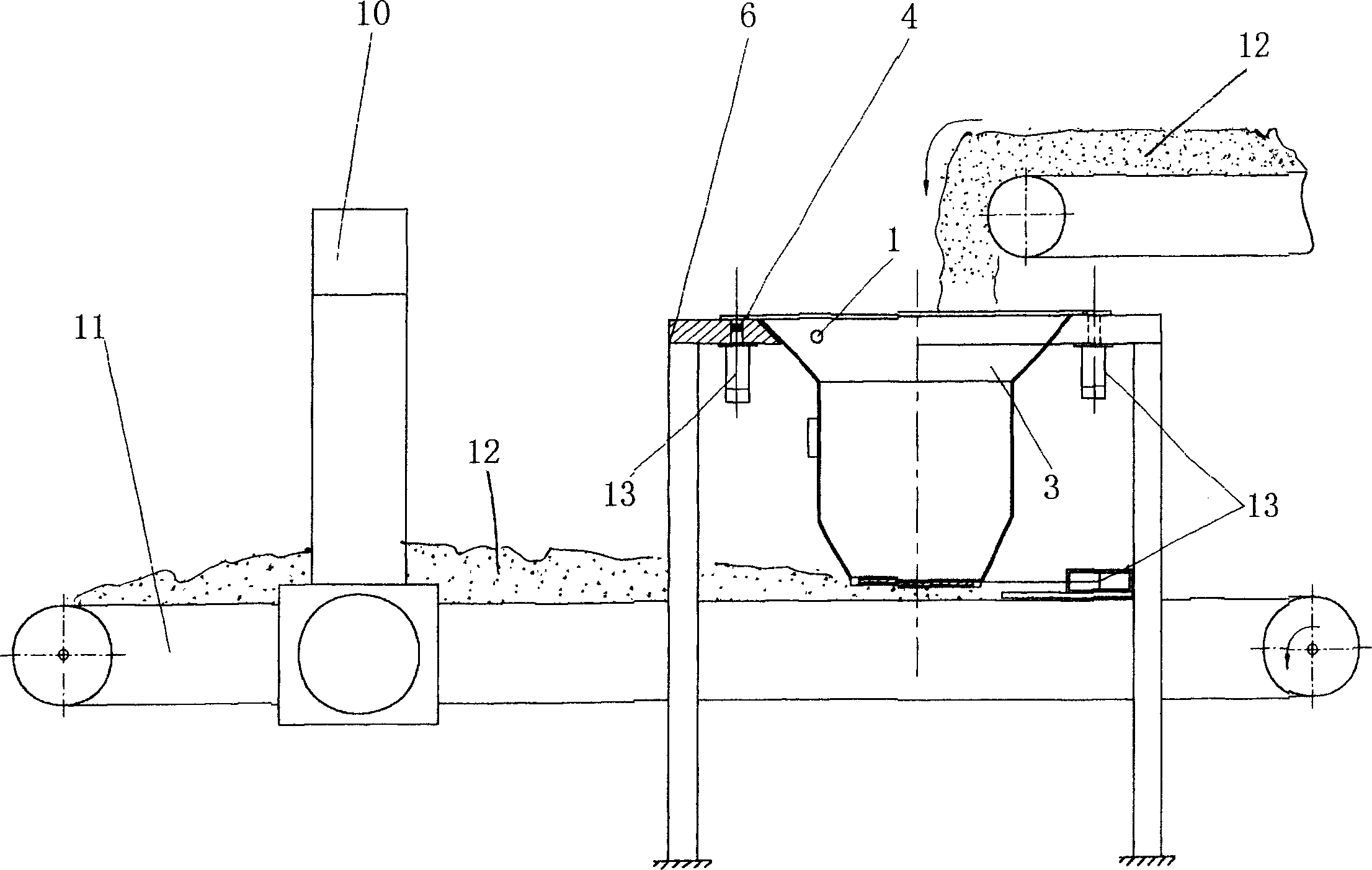

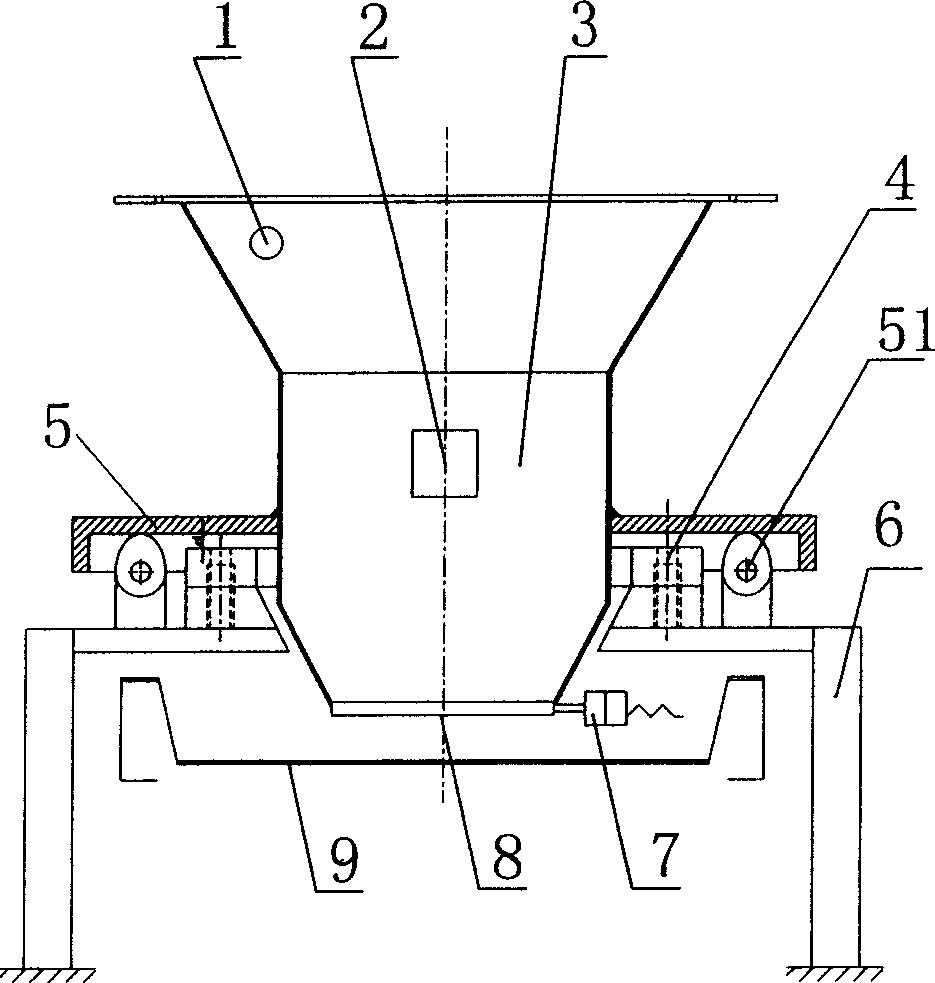

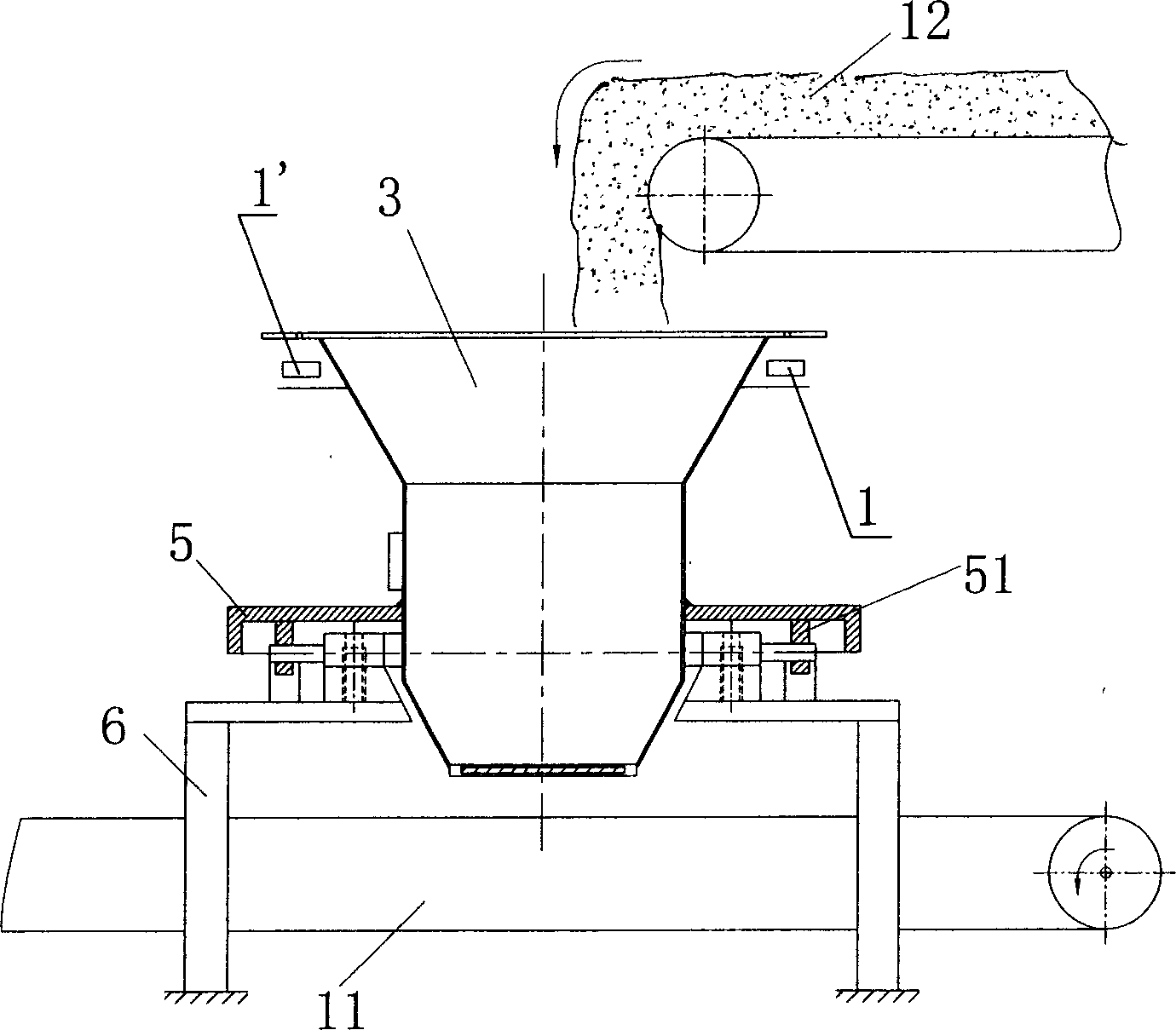

[0033] exist figure 1 , Figure 1a , Figure 1b , Figure 4a and Figure 4b Among them, an automatic physical calibration system for a nuclear scale shown in the present invention includes: a photoelectric level gauge 1, an electromagnetic vibrator 2, an automatic feeding bin 3, a weighing device 4, a bin lifting device 5, and a supporting base 6. Electric pulley pumping plate 7, feeding port 8, conveyor belt 9, nuclear scale 10, belt conveying device 11, material 12, hydraulic cylinder 13 and control device, etc. Wherein, the photoelectric material level gauge comprises a material level gauge generator 1 and a material level gauge receiver 1'. The bin lifting device 5 and the weighing device 4 are all fixed on the support base 6, and the feeding bin 3 can be placed on the bin lifting device 5 or on the weighing device 4, depending on the configuration of the bin lifting device 5. Depends on working status. The supporting base 6 is straddled on the belt conveyor 11 . Au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com