Modular underbody for a motor vehicle

A technology for motor vehicles and mold components, which is applied in the direction of motor vehicles, vehicle parts, load-bearing body structures, etc., and can solve the problems of unusable side beams and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

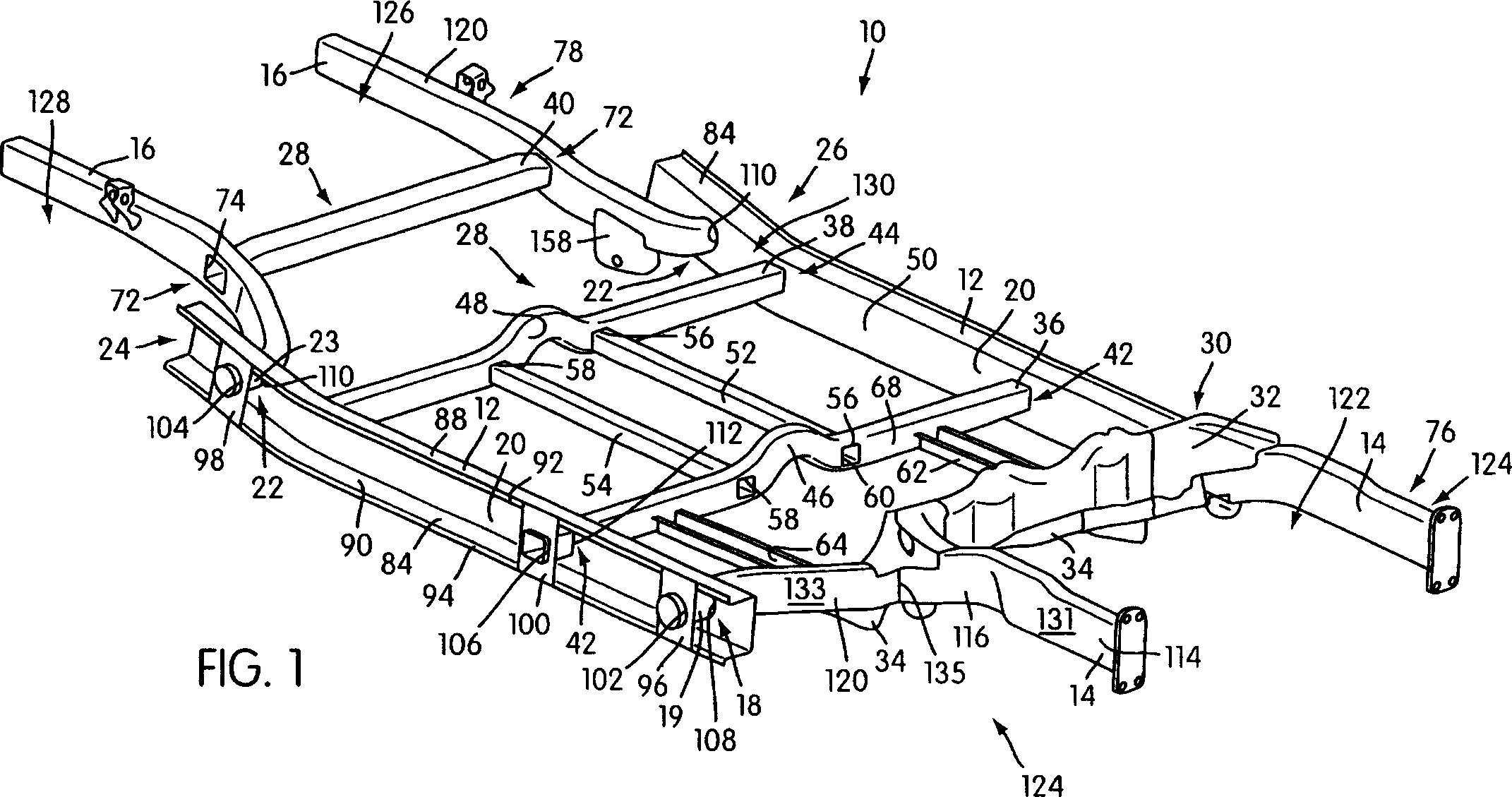

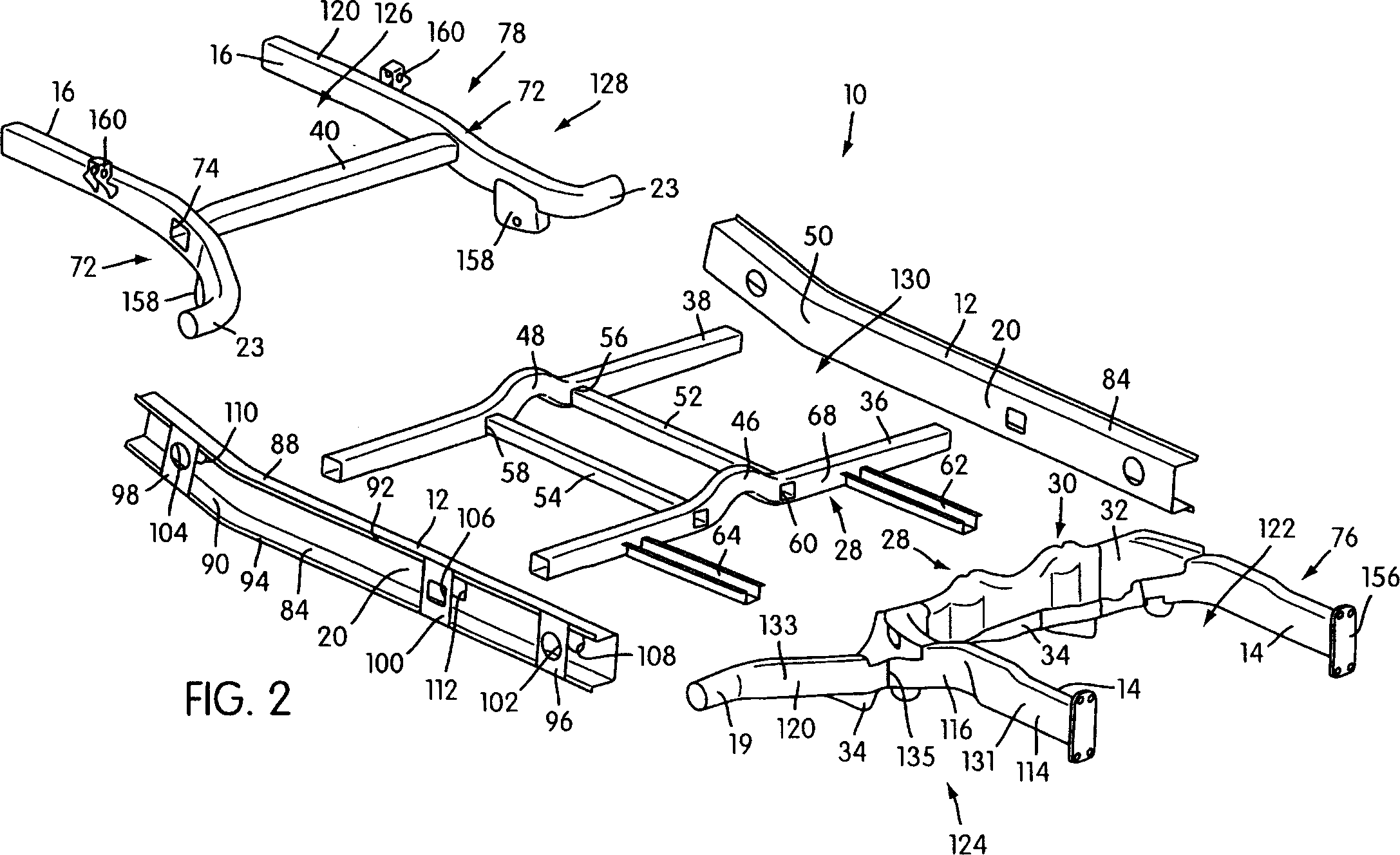

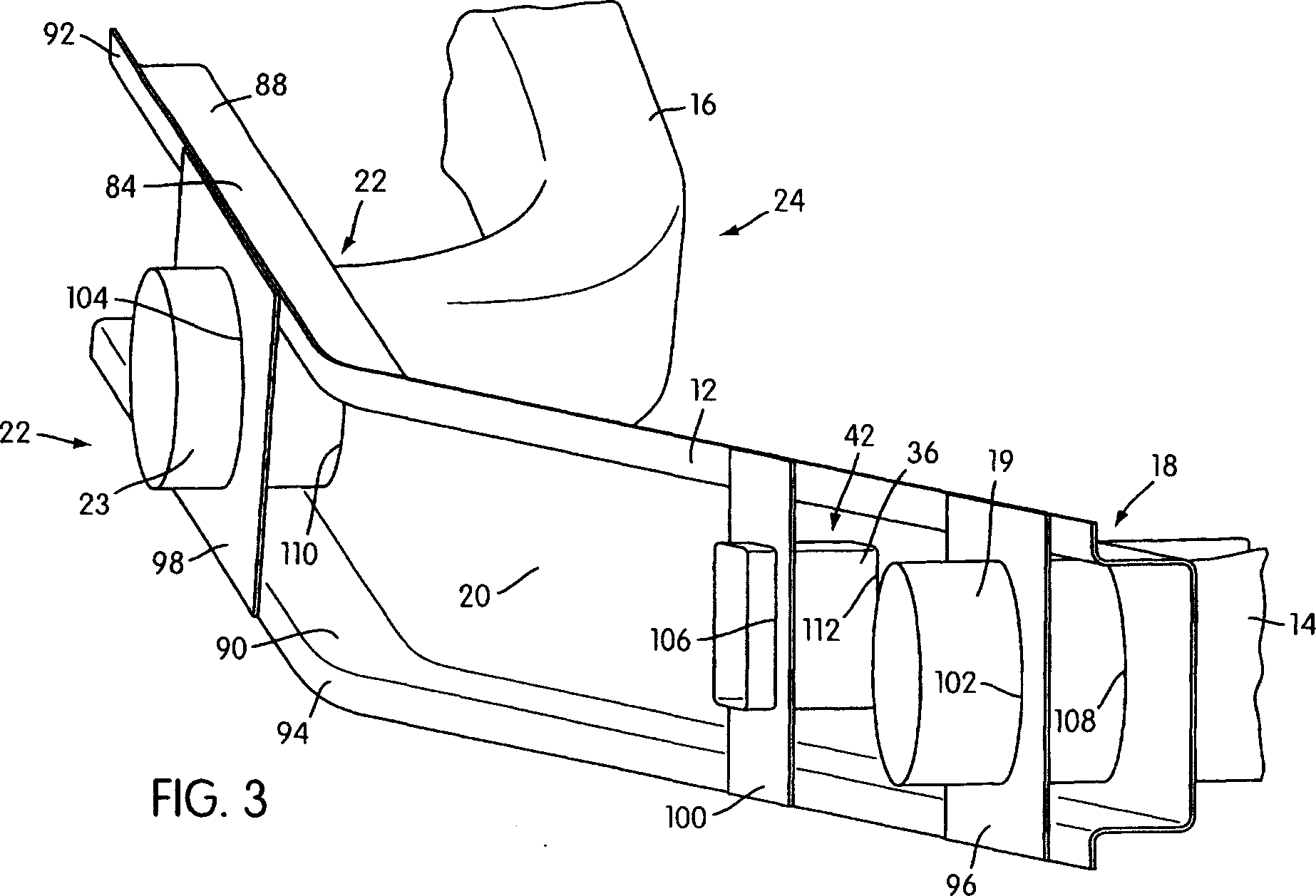

[0022] FIG. 1 is an illustration of an embodiment of a modular underbody frame 10 for a motor vehicle in accordance with the principles of the present invention. FIG. 2 shows a partially exploded view of the vehicle frame 10 . The frame 10 includes a pair of laterally spaced, longitudinally extending central side member structures 12 , a pair of front side member structures forming a front assembly 76 , and a pair of rear side member structures forming a rear mold assembly 78 .

[0023] The use of the mold assemblies 76, 78 with the center side member structure 12 has great versatility in forming the vehicle frame 10 or in forming other vehicle frames. For example, in the production of other vehicle frames, the mold assemblies 76 and 78 may be used together or separately with other center side member structures. Thus, significant savings can be achieved by applying the mold assemblies 76 and 78 to other motor vehicle frames. Alternatively, the mold assemblies 76 and 78 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com