Flexible bend running technology for electric single-beam crane

A crane and single girder technology, applied in cranes, walking bridge cranes, rail systems, etc., can solve problems such as large waste of funds and manpower, large amount of equipment installation and troublesome maintenance of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

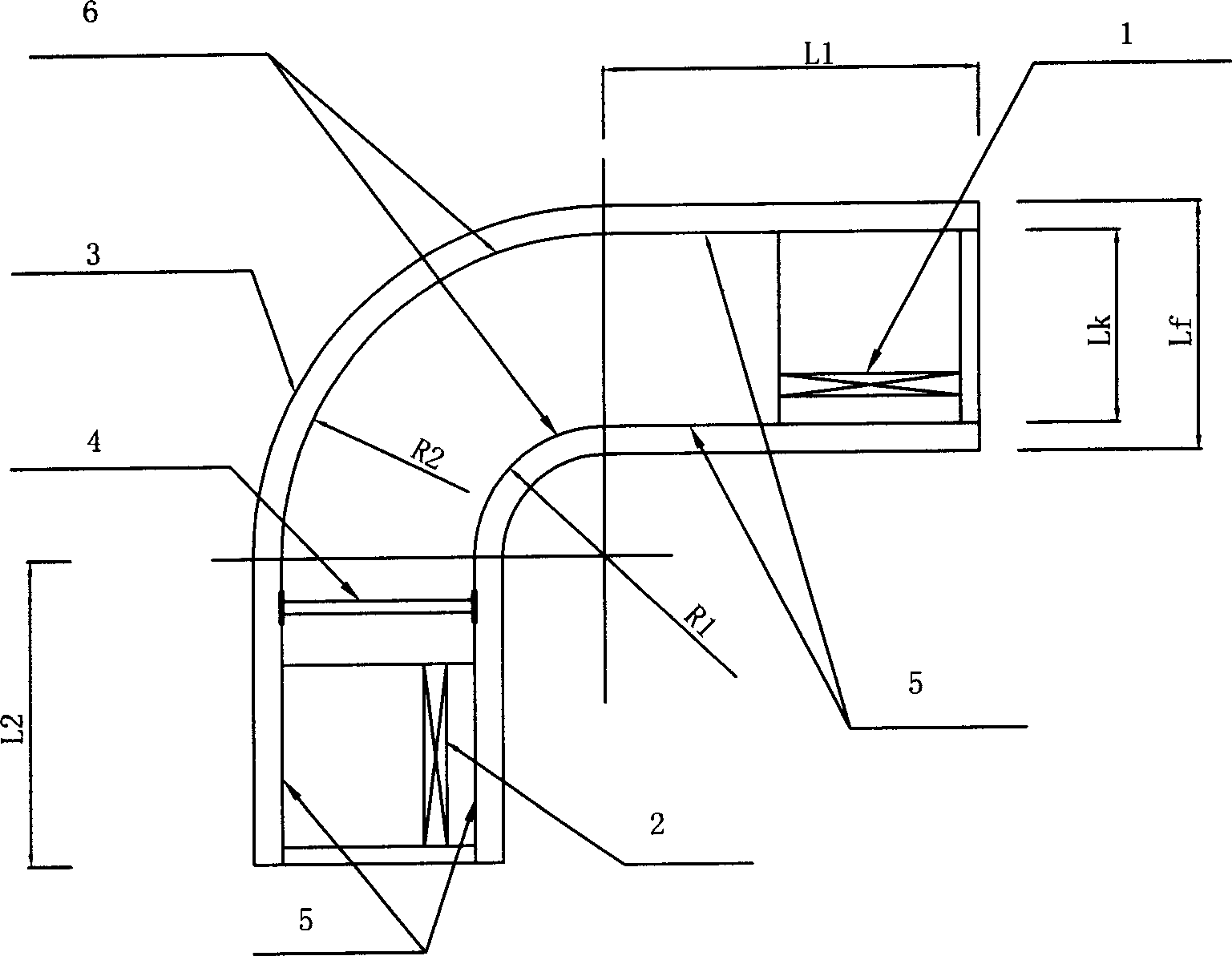

[0015] Example 1, using the electric single-girder crane curved track operation technology to solve the problem of dispatching and transporting two sluices sharing a set of maintenance gates

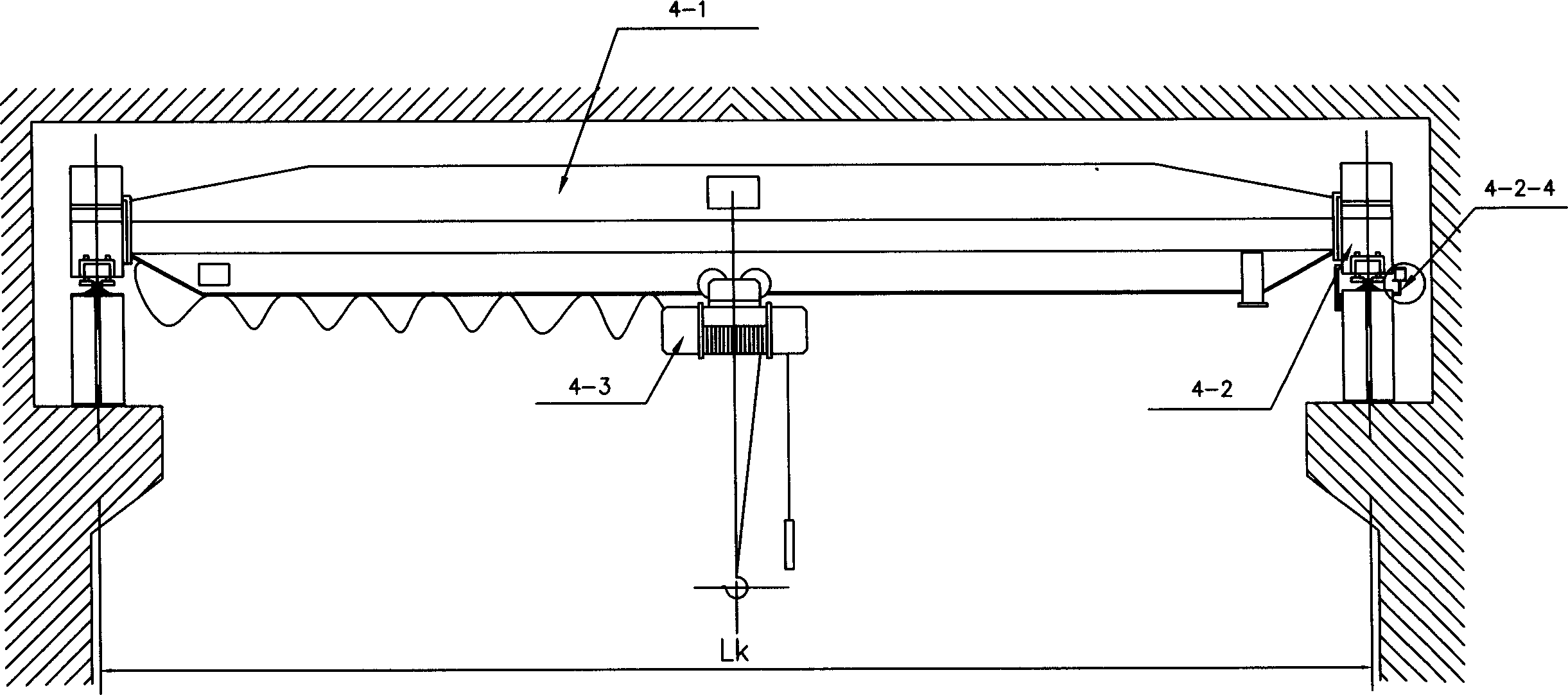

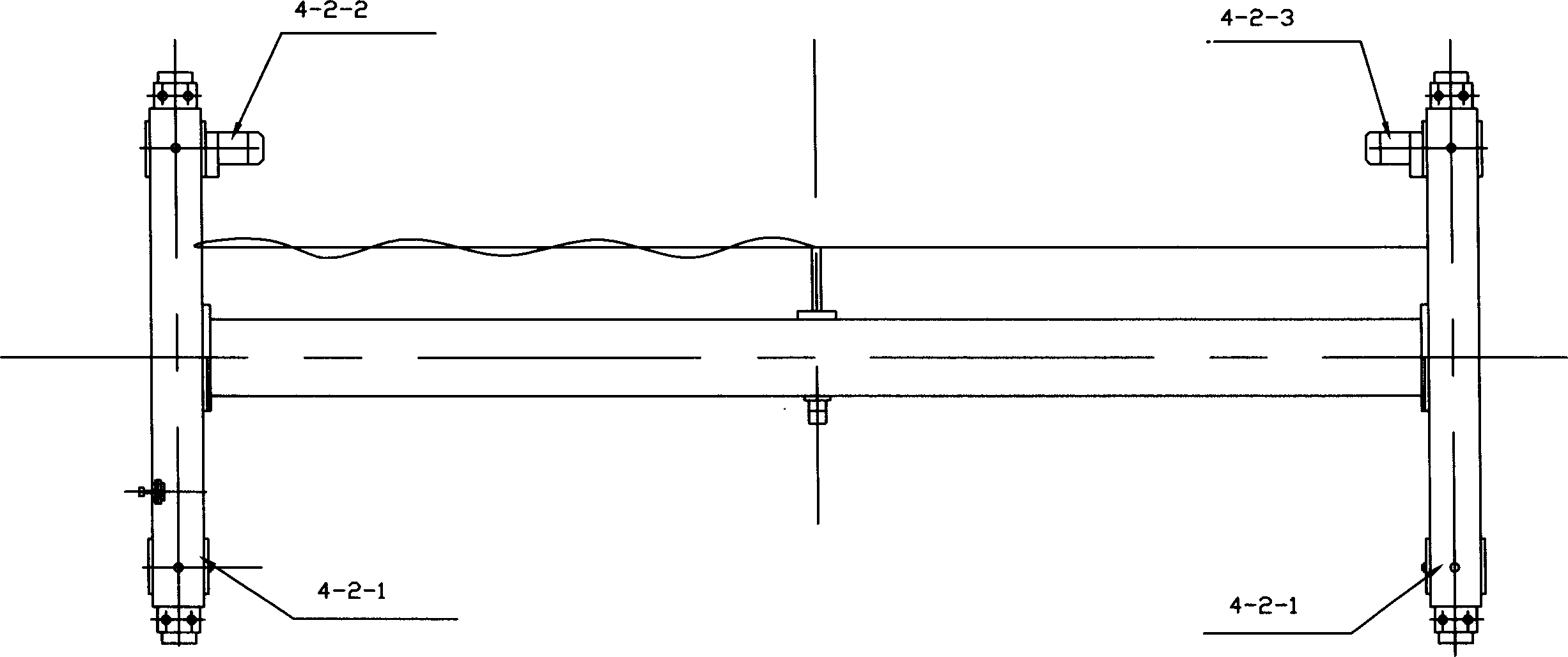

[0016]The two sluices at the "T"-shaped intersection of the river share a set of maintenance gates and lifting devices for gate maintenance to meet the lifting requirements of the maintenance gates. The lifting device model is LDA type 5-ton electric single-girder crane with a span of 8.5 meters and a lifting height of 18 meters. The design weight of a single maintenance gate is 2.6 tons. 26 meters. The inner arc radius of the arc section at the 90° intersection of the two gate tracks is R7500 mm, and the outer arc and inner arc have the same center. The end beam wheel running mechanism of the original electric single-girder crane has been changed. The running mechanism adopts double-sided drive and is composed of steering wheels, single-speed drive motors, double-speed drive motors, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com