Hybrid powertrain system

A technology of power transmission system and transmission speed ratio, applied in the direction of hybrid vehicles, transmission devices, power devices, etc., can solve the problems of complex hardware and control systems, regenerative braking needs, etc., to improve the quality of gear shifting and realize automatic power The effect of shifting gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

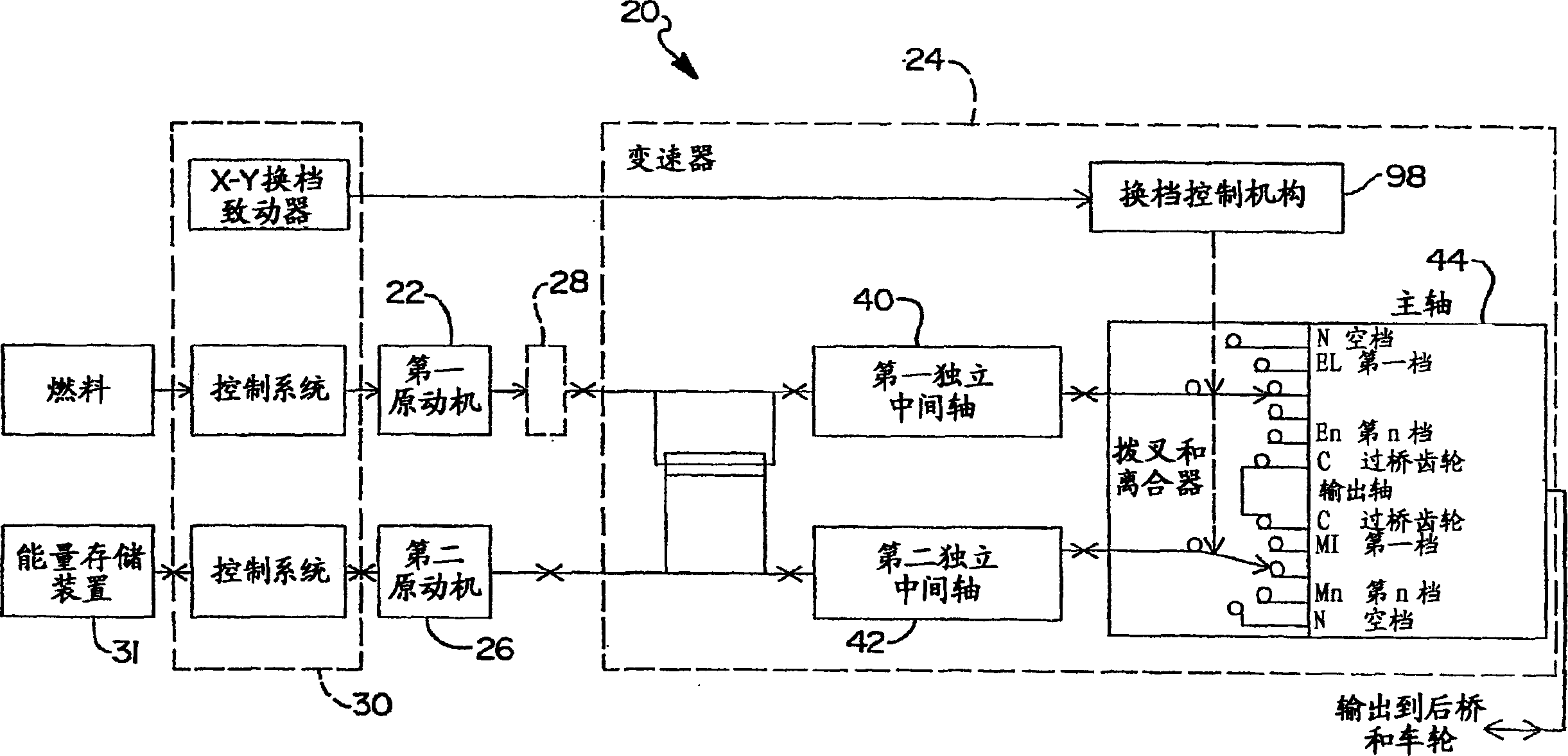

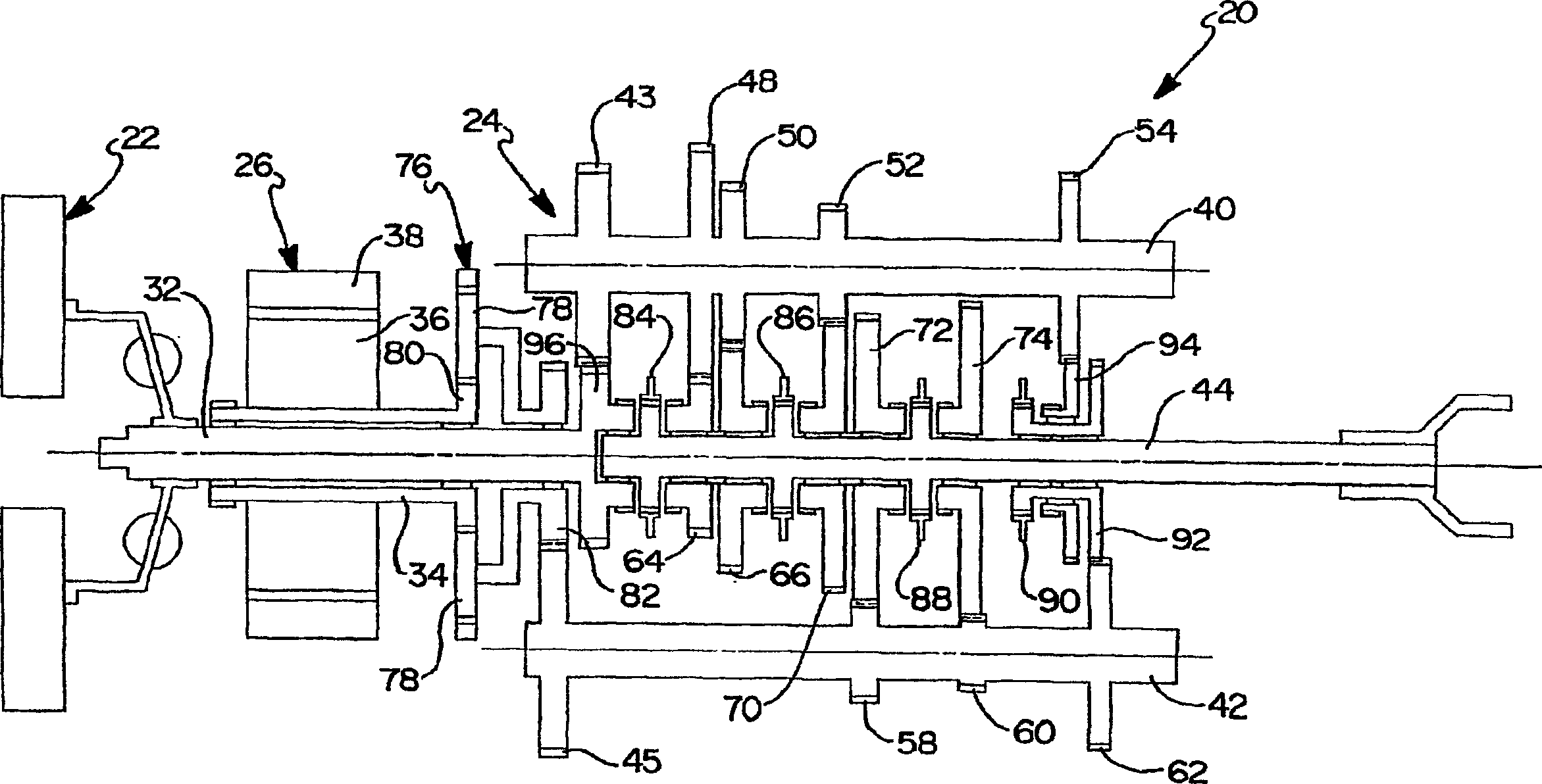

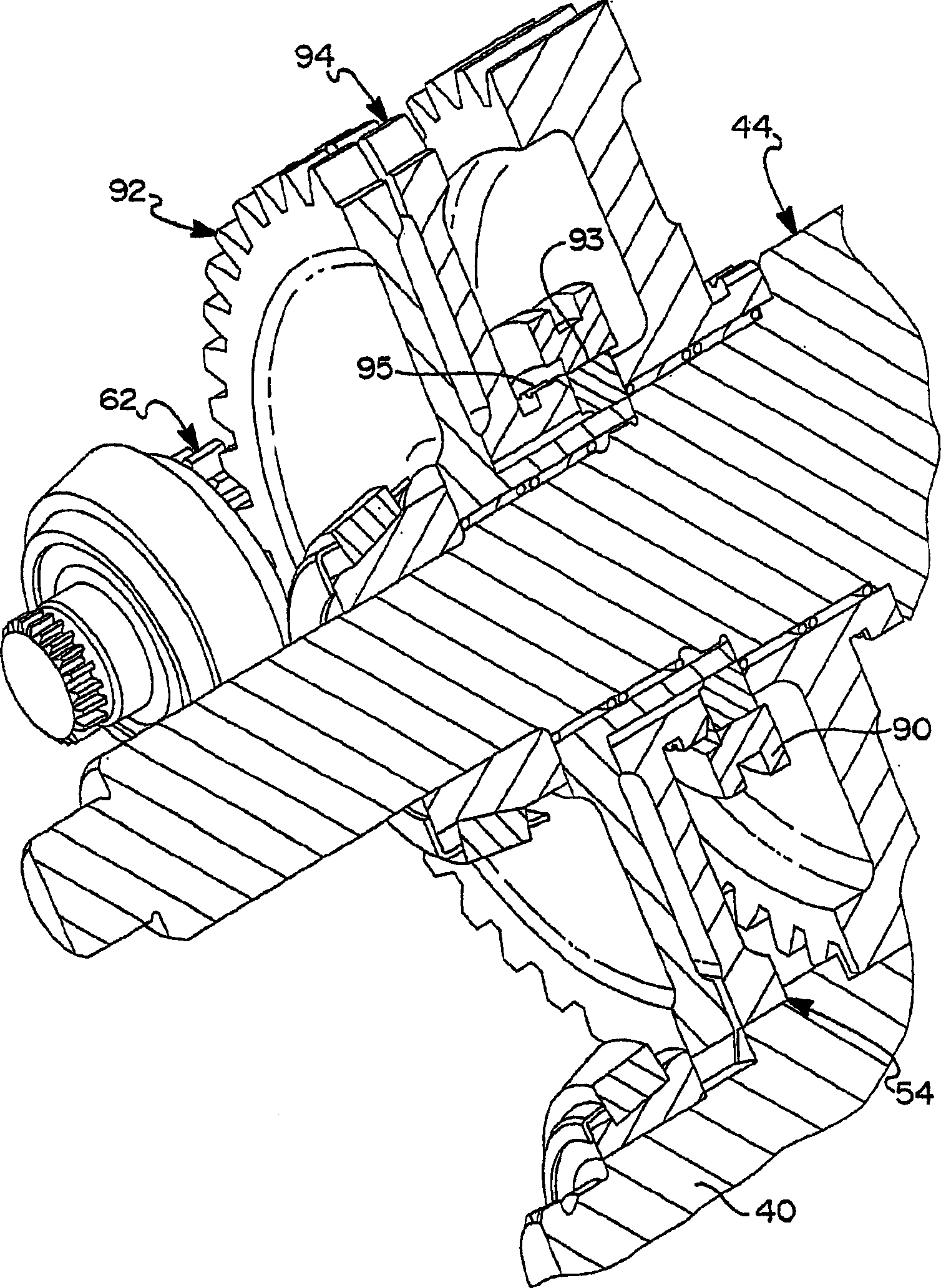

[0022] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. refer to figure 1 , the hybrid powertrain 20 includes a first prime mover 22, such as a spark ignition internal combustion engine and a compression ignition internal combustion engine; a shift / shift gear transmission 24 and a second prime mover 26, such as an electric motor / generator or a hydraulic motor / pump. The hybrid powertrain 20 is selectively provided with a master clutch 28 (shown in phantom), such as a master friction clutch, which is selectively operable to disengage the first prime mover 22 from the transmission 24 .

[0023] An electronic control unit (ECU) 30 is installed in the power transmission system 20 for controlling the first prime mover 22 , the second prime mover 26 and the transmission 24 . ECU 30 preferably includes a conventional programmable digital computer (not shown) configured to accept various input signals includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com