Stroke frequency regulating apparatus of oil pumping machine

A technology of regulators and pumping units, which is applied in the direction of mechanical equipment, mining fluids, gear transmissions, etc., can solve the problems of not being able to meet the development requirements, time-consuming and laborious disassembly, and inconvenient operation, so as to avoid impact, make manufacturing convenient, and mechanism compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

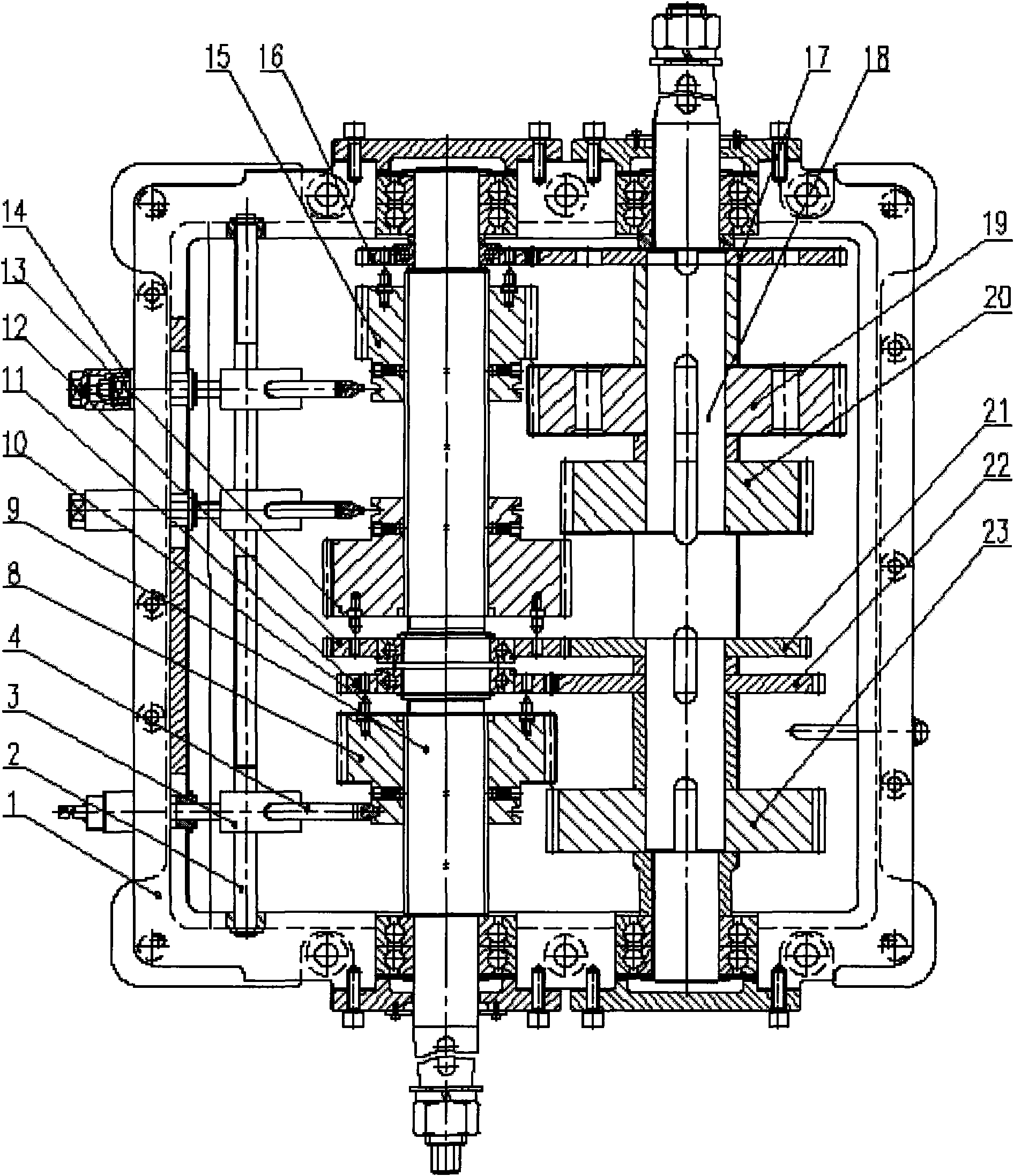

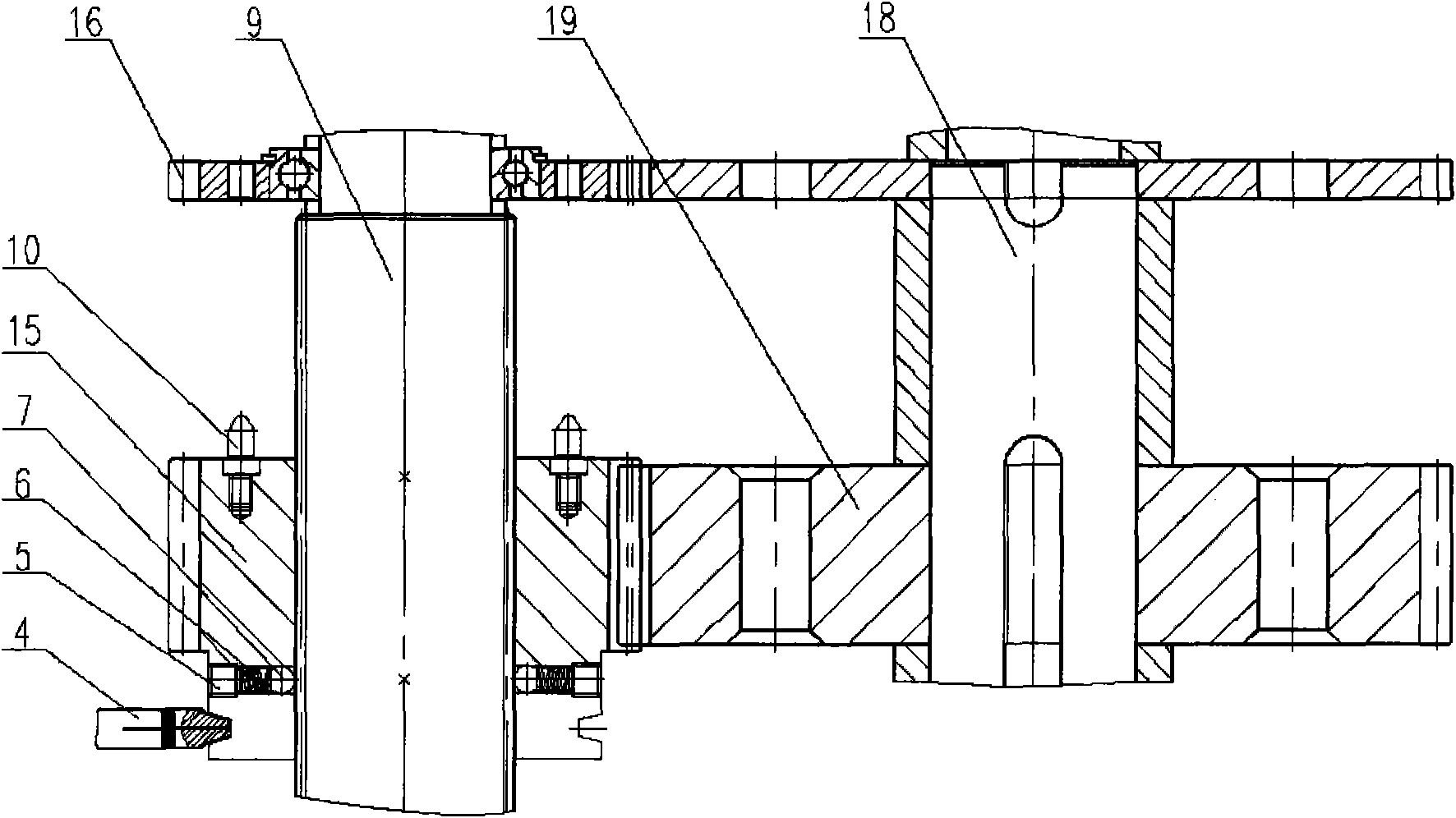

[0014] The stroke frequency regulator of the pumping unit consists of a machine base (1), a slide rod (2), a shift fork slider (3), a shift fork fork head (4), a hexagon socket set screw (5), a compression spring ( 6), steel ball (7), third gear transmission pinion (8), input shaft (9), positioning pin (10), third gear synchronous pinion (11), second gear synchronous pinion (12), second gear shift pinion (13), shift handle (14), first gear shift pinion (15), first gear synchronous pinion (16), first gear synchronous gear Gear (17), output shaft (18), first gear shift gear (19), second gear gear shift (20), second gear synchronous gear (21), third gear synchronous gear The gear (22), the third gear shift gear (23) etc., the input shaft (9) and the output shaft (18) are installed on the base (1) through bearings; the first gear synchronous pinion (16) , the first gear shift pinion (15), the second gear shift pinion (13), the second gear synchronous pinion (12), the third gear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com