Intake arrangement

A technology of air intake device and air intake channel, which is applied in the direction of fuel air intake, charging system, combustion air/combustion-air treatment, etc. Deterioration of engine exhaust emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

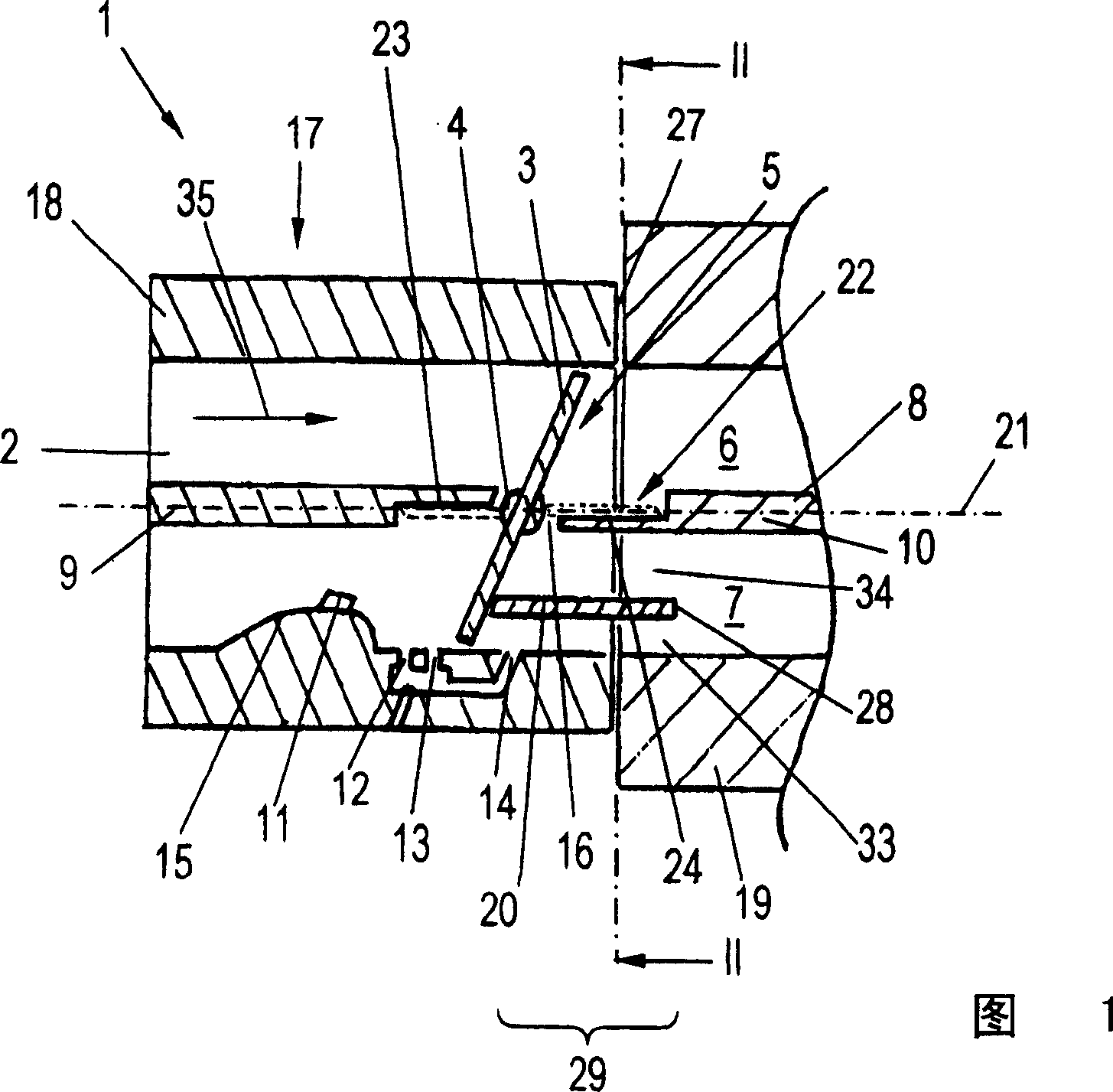

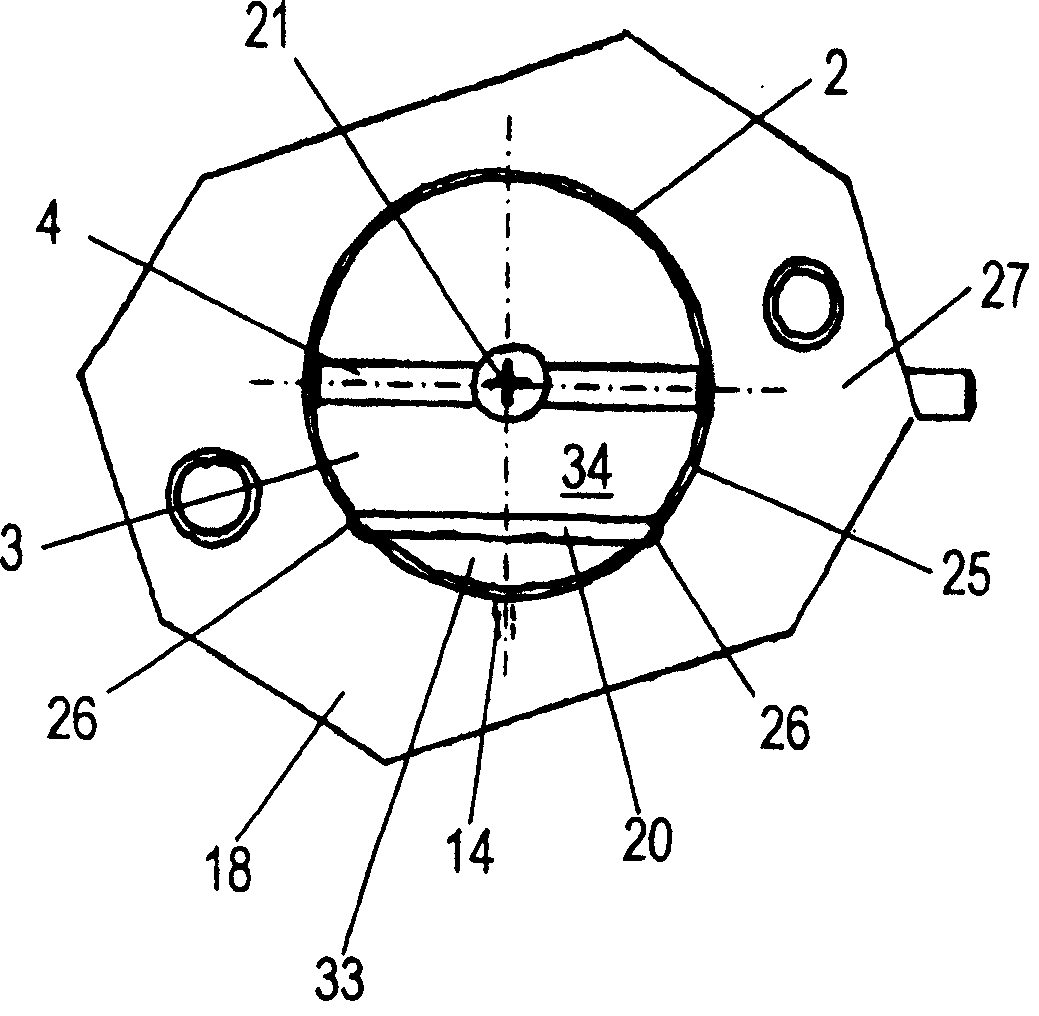

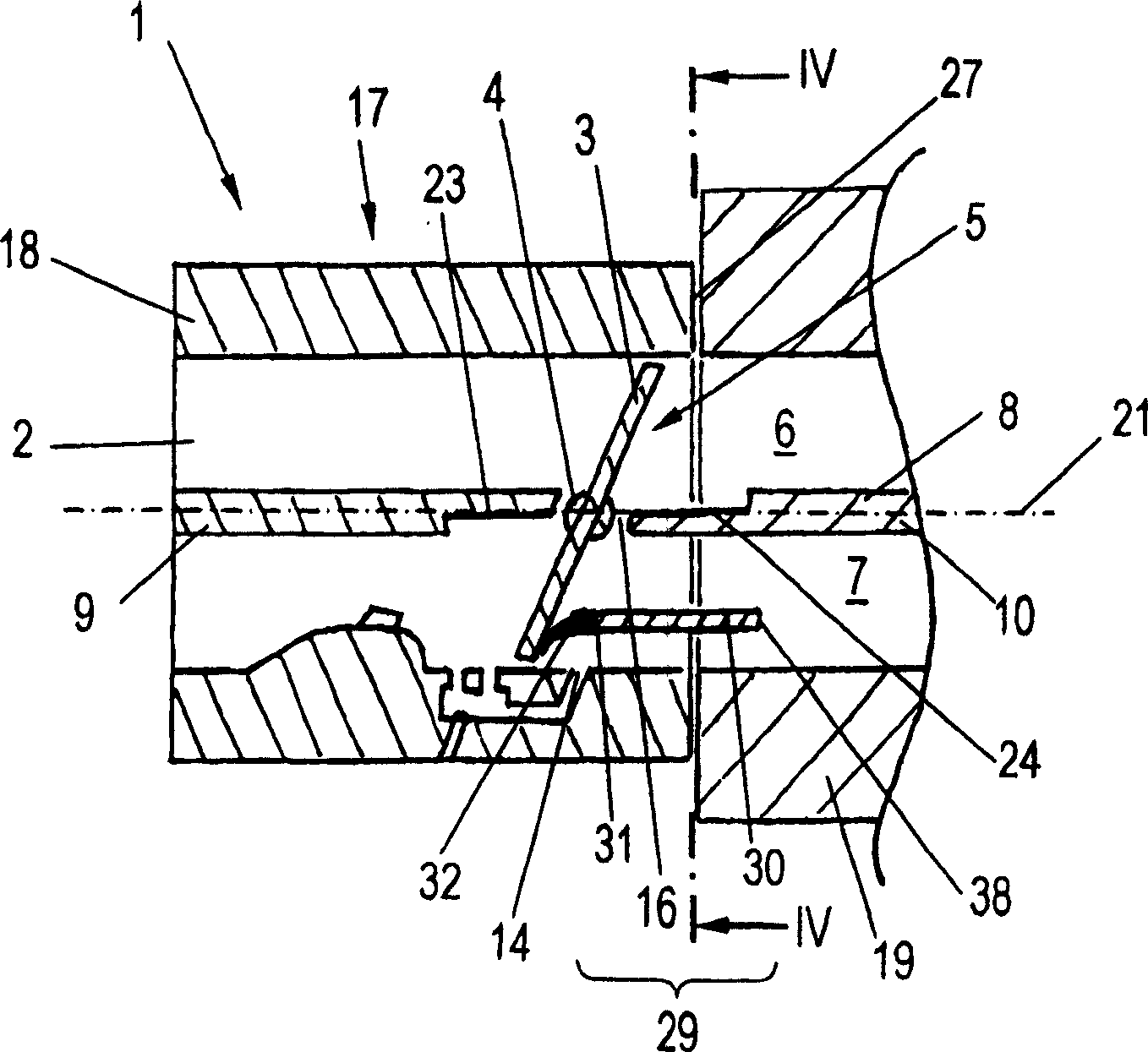

[0014] FIG. 1 shows an air intake device 1 for introducing combustion air into a two-stroke engine, in particular for a hand-held tool, such as a chainsaw, free-cut cutter or the like. The intake device 1 has an intake duct 2 , in which a throttle valve 3 is mounted pivotably by means of a throttle shaft 4 , wherein the throttle valve 3 is arranged in a carburetor 17 . An air filter, which is not shown in FIG. 1 , can be installed upstream of the carburetor 17 in the direction of flow 35 . A flange 19 is arranged downstream of the carburetor 17 , which can be, for example, a flange of a two-stroke engine. However, it can also be an intermediate flange. The partition wall 8 divides the intake channel 2 into an air channel 6 and a mixture channel 7 . In this case, the partition wall section 9 is upstream of the throttle valve 3 and the partition wall section 10 is downstream of the throttle valve 3 . Advantageously, the partition wall 8 extends over the entire length of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com