Cap for ink jet head

An inkjet head and inkjet technology, applied in printing and other directions, can solve problems such as clogged nozzles and nozzle ink drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

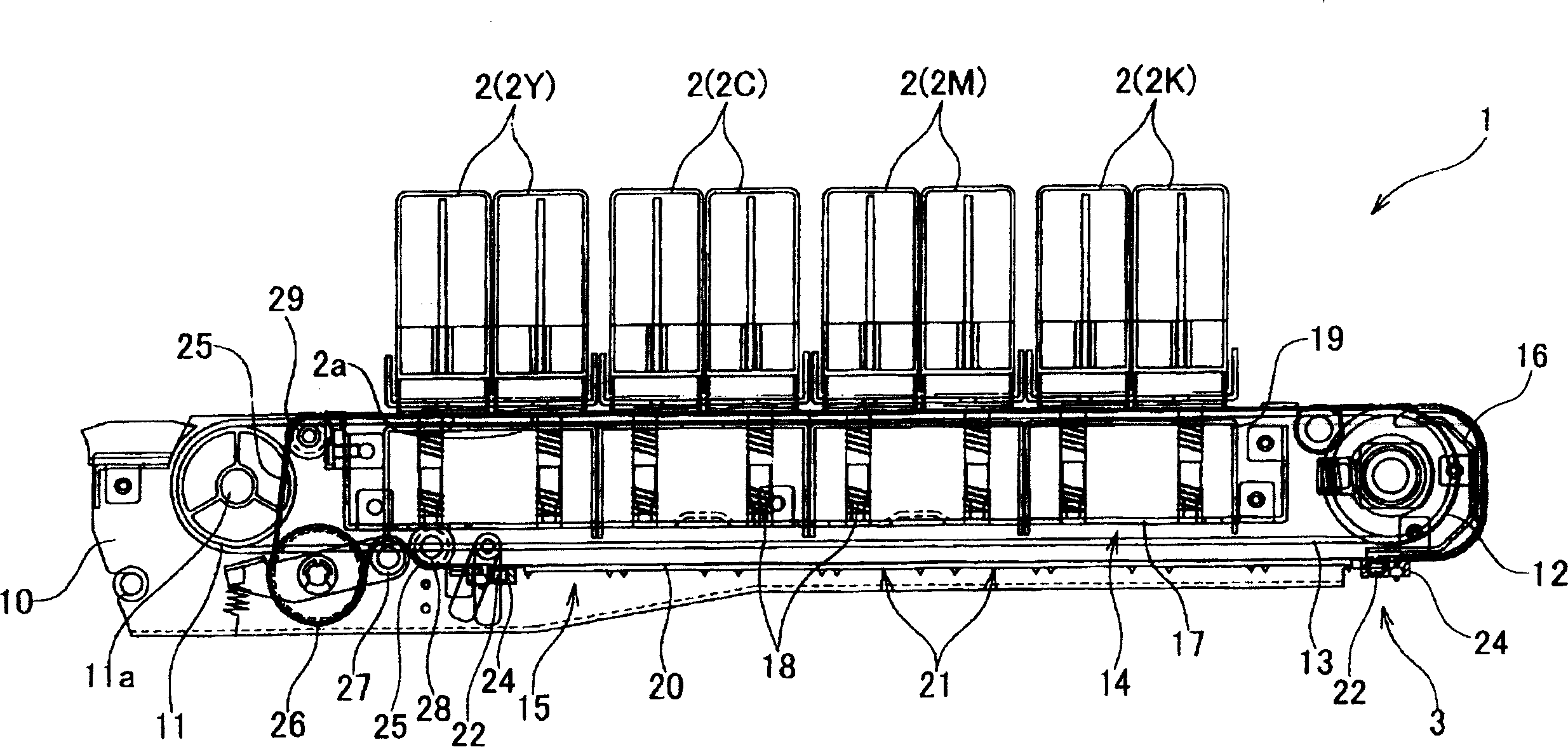

[0020] A preferred embodiment for carrying out the present invention is described below. In the preferred embodiment, the present invention is applied to a linear color inkjet printer. However, the present invention can also be applied to other types of inkjet printers.

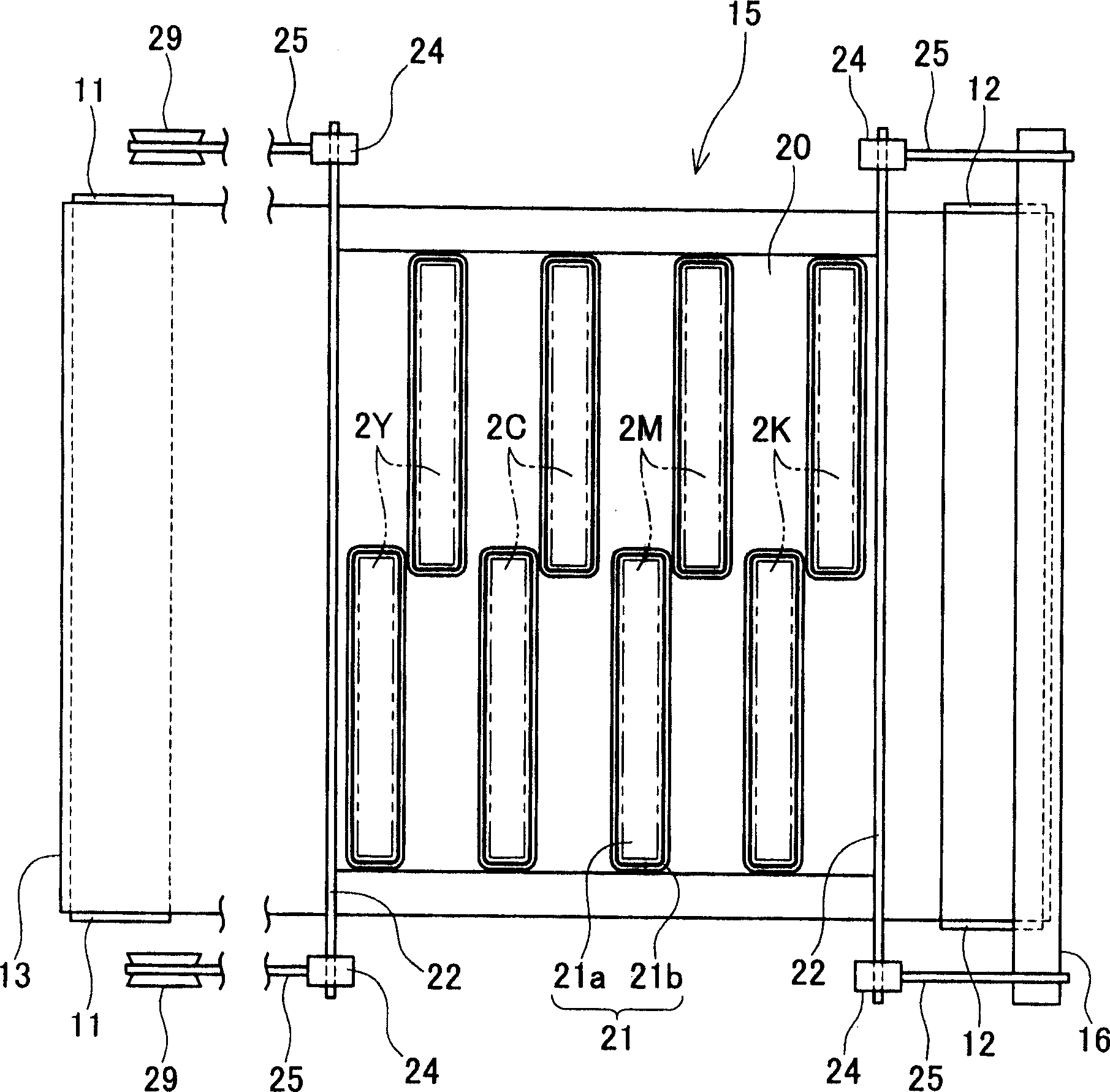

[0021] Such as figure 1 As shown, the inkjet printer 1 is provided with a total of eight linear inkjet heads 2 . The two inkjet heads 2K eject black ink, the two inkjet heads 2M eject magenta ink, the two inkjet heads 2C eject cyan ink, and the two inkjet heads 2Y eject yellow ink. The inkjet printer 1 is also provided in figure 1 Transport unit 3 that transports paper in the left direction. Eight inkjet heads 2 in figure 1 line up in the left-to-right direction (along the direction in which the paper is fed).

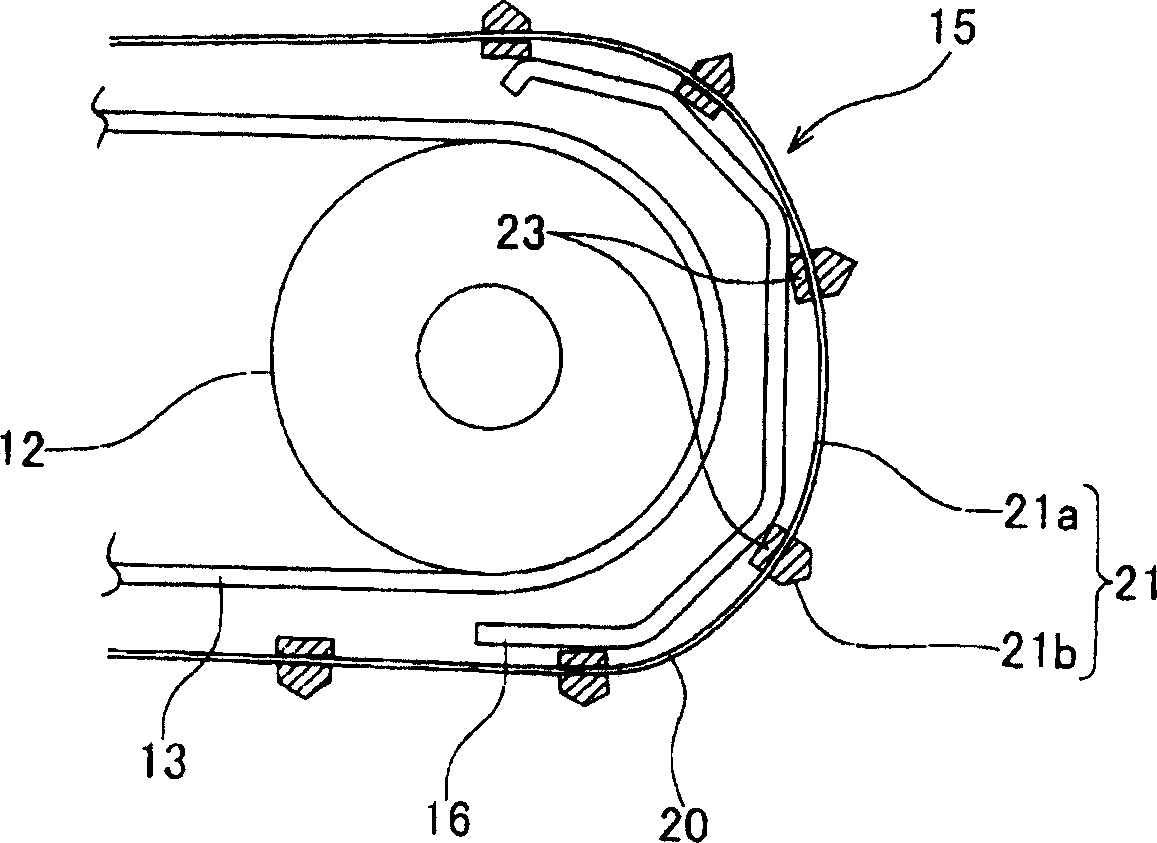

[0022] An ink ejection surface 2 a is formed on the lower surface of each ink jet head 2 . Such as Figure 5 As shown, in the ink ejection surface 2a of each ink jet head 2, a plurality of hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com