Drive force control method for four-wheel drive vehicle

一种四轮驱动、控制方法的技术,应用在传动装置控制、控制装置、车辆部件等方向,能够解决没有驱动力控制公开、没有任何提及轮胎接地负荷负荷均匀、不能充分把握车身动向等问题,达到减少反转向、消除不稳定状态的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

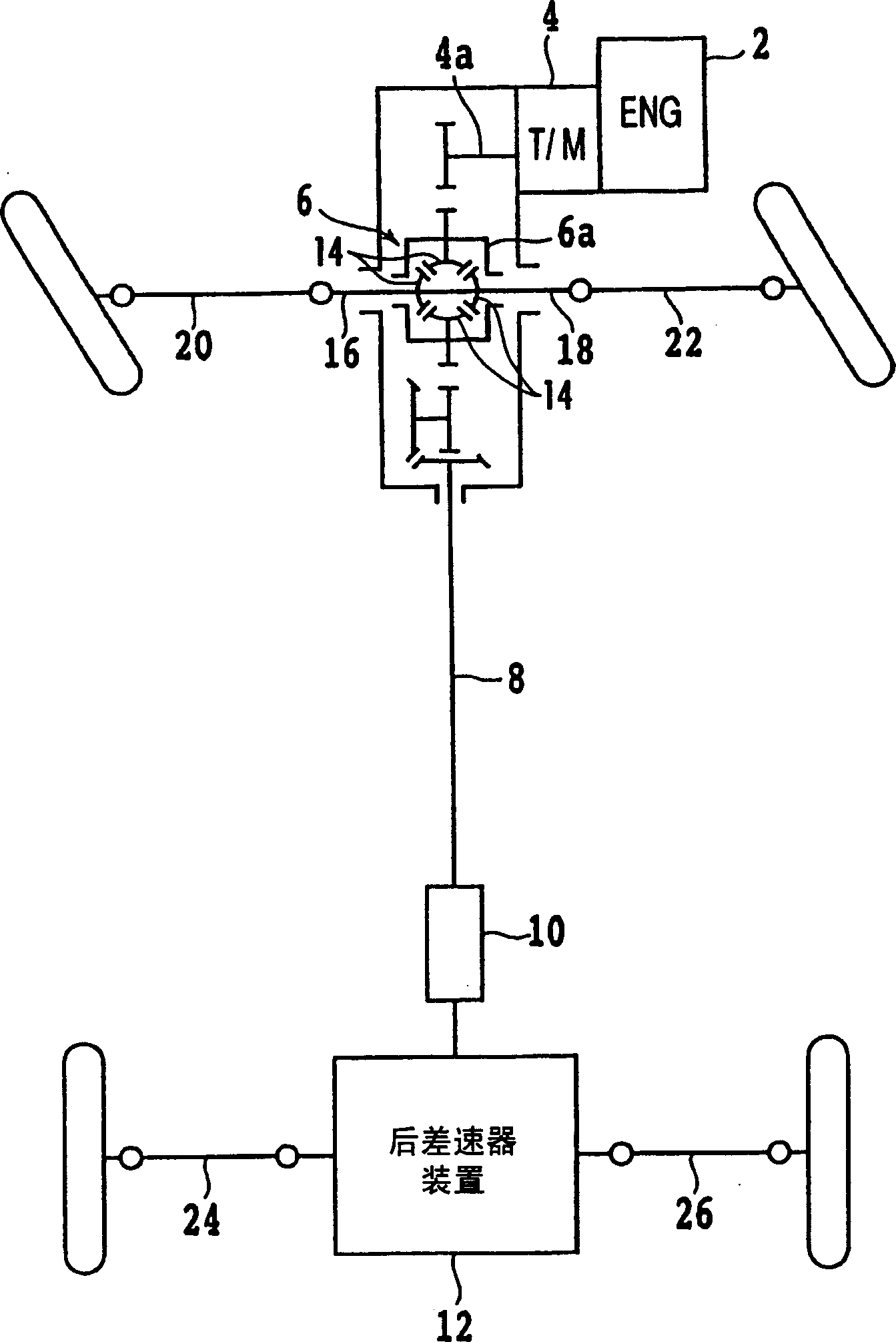

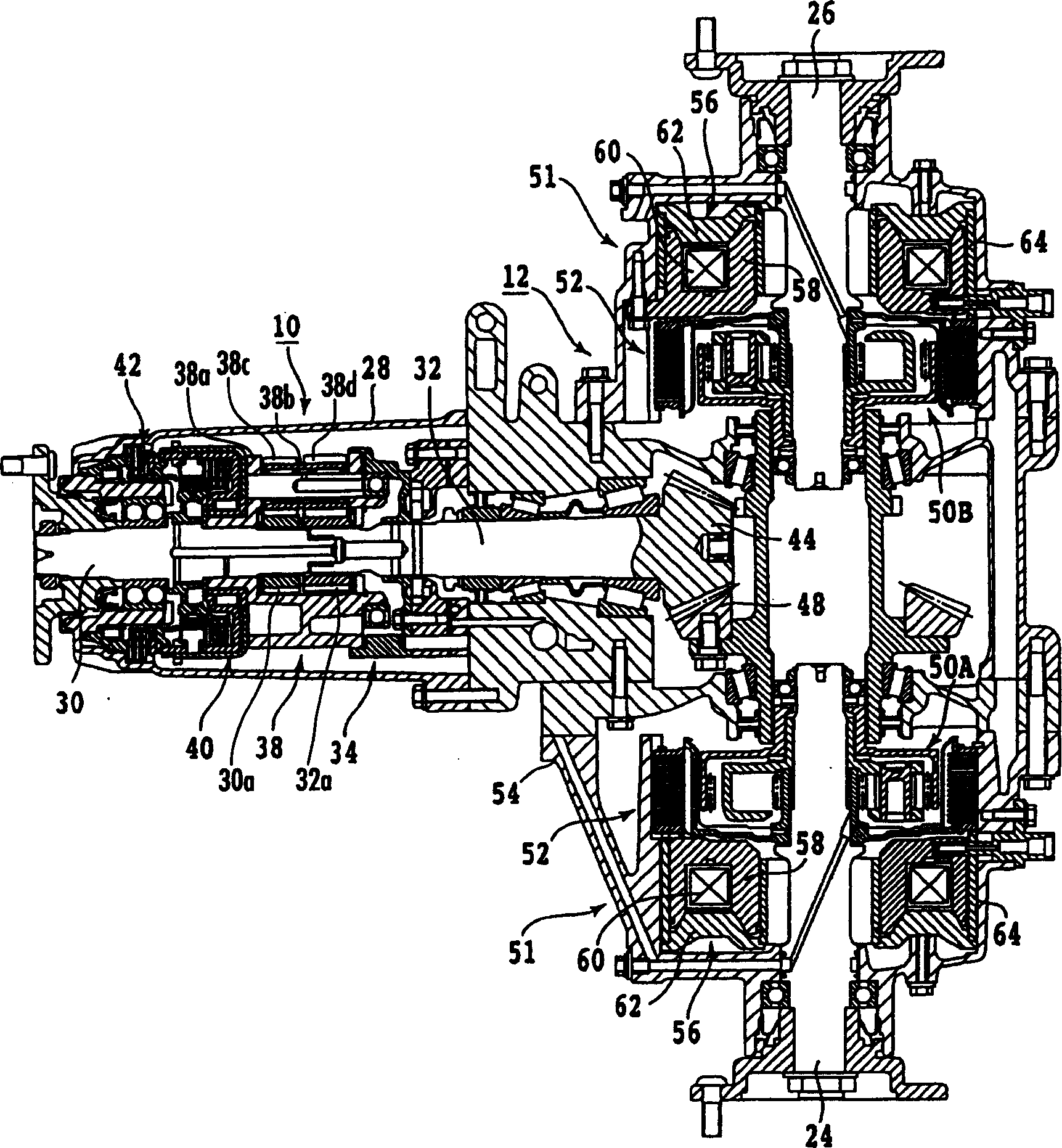

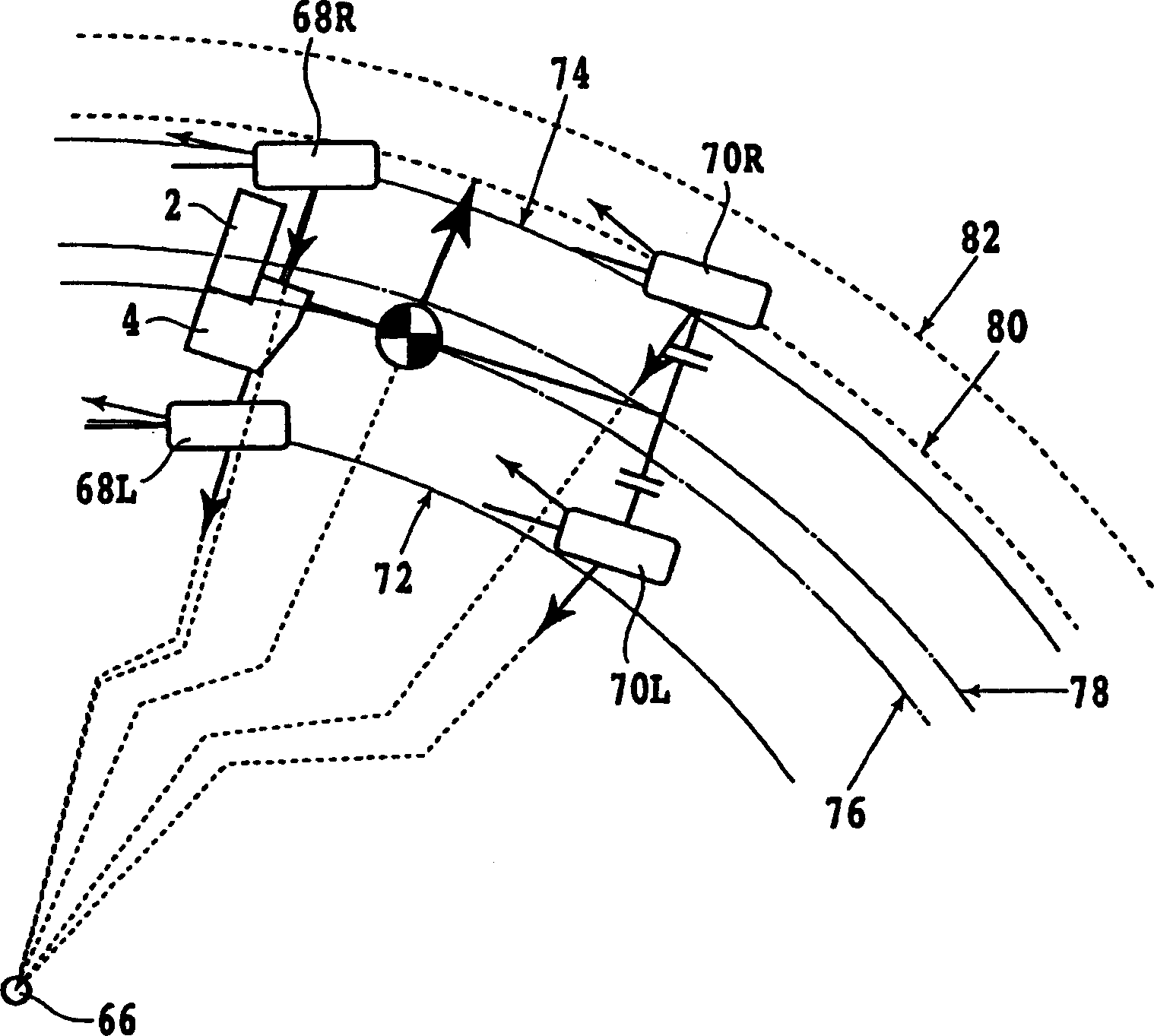

[0043] refer to figure 1 , which shows a schematic diagram of a power transmission device of a four-wheel drive vehicle having a front-engine front-wheel drive (FF) chassis of a speed increasing device (transmission device) 10 . like figure 1As shown, the power transmission system of the four-wheel drive vehicle mainly includes: a front differential device 6 receiving power from an engine 2 disposed in front of the vehicle transmitted from an output shaft 4a of a transmission 4; A speed-up device (transmission device) 10 that receives power from the front differential device 6 , and a rear differential device 12 that receives power transmitted from the speed-up device 10 .

[0044] The front differential device 6 has a conventionally known structure, and transmits the power from the output shaft 4a of the transmission 4 to the left and right front wheel drive shafts 20 via a plurality of gears 14 and output shafts 16, 18 in the differential case 6a. , 22, and drive each fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com