Recovery of adiponitrile from a mixture of adiponitrile, aminocapronitrile and hexamethylenediamine

A technology of bis-hexamethylenetriamine and cyanocyclopentylene imine, which is applied in the field of ADN and can solve problems such as the inability to separate BHMT from CPI

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

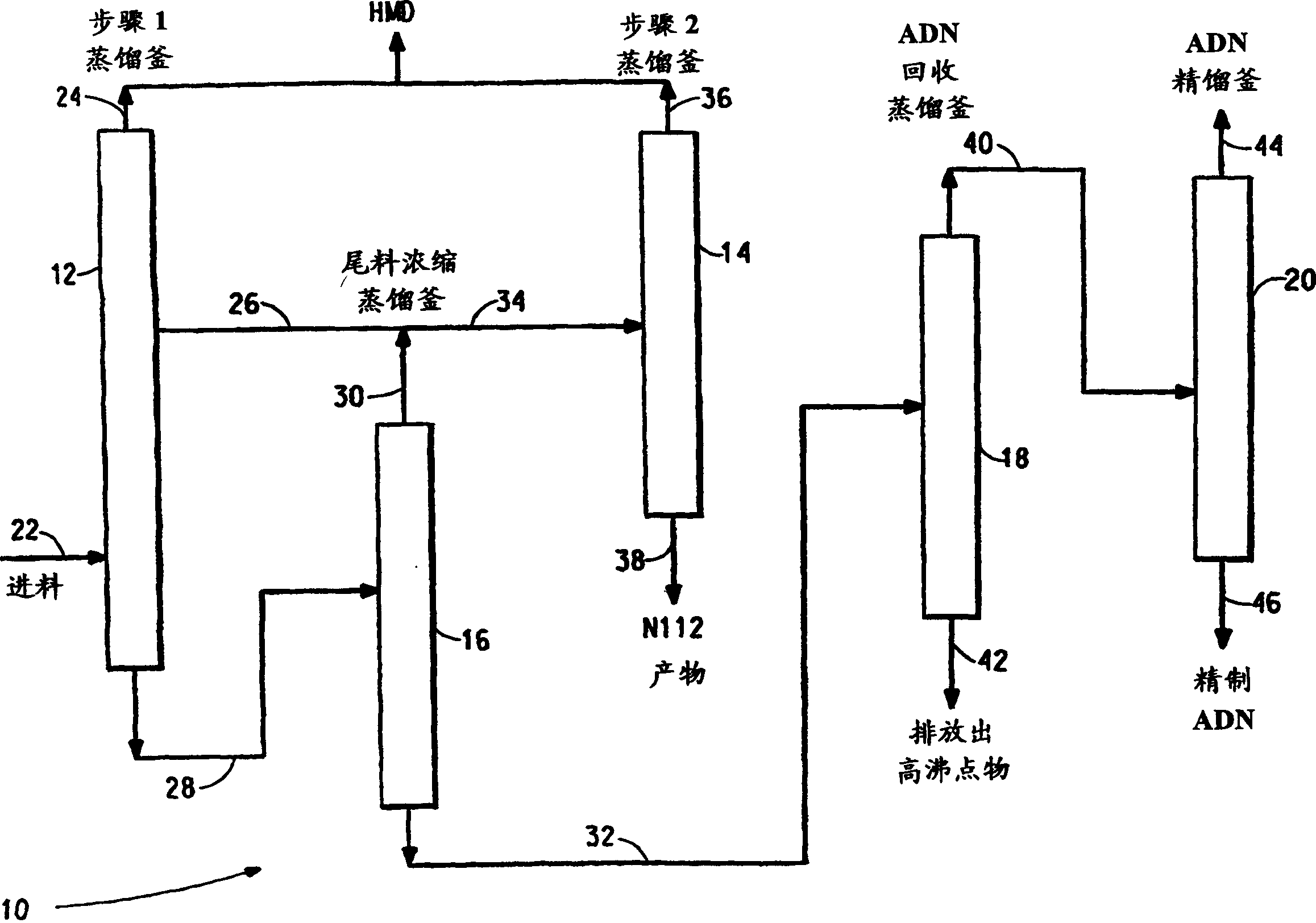

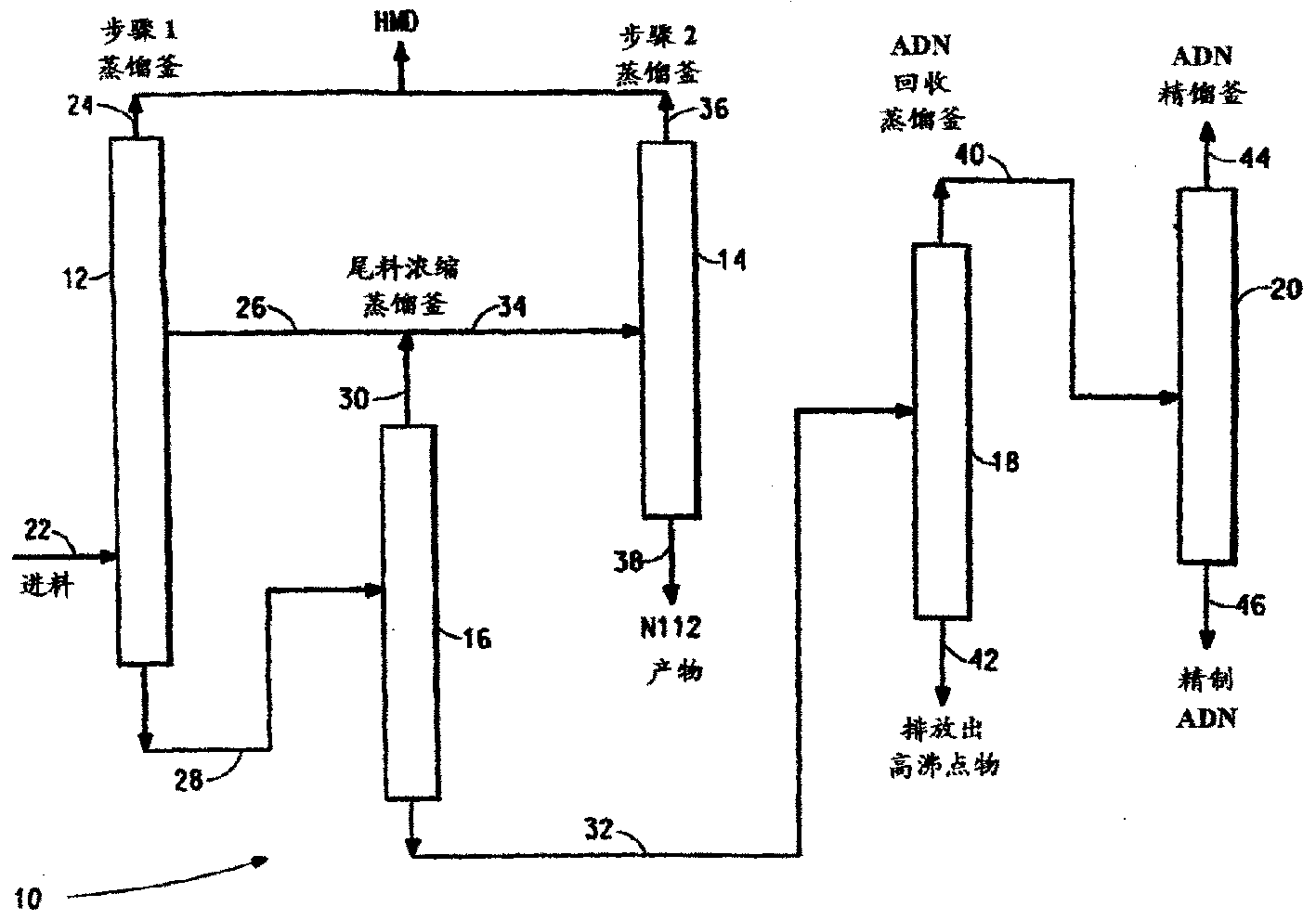

[0019] The process of the present invention was performed in a stepwise fashion (as opposed to a continuous, bulk operation) to evaluate the ability of the process to produce refined streams of HMD, ACN and ADN. Reference numbers are shown in parentheses. All percentages are by weight. The notation "ND" in the table indicates not detectable. Throughout the specification and drawings, the expressions "still pot" and "distillation column" are interchangeable.

[0020] Feed (22) was prepared by blending crude HMD with refined ACN and refined ADN. The nominal composition of the feed was: 40% HMD, 40% ACN and 20% ADN. Impurities consisting of conventional impurities such as hexamethyleneimine (HMI), diaminocyclohexane (DCH), BHMT, etc. are present in crude HMD. Air was bubbled through the feed mixture such that the THA in the feed was about 300 ppm.

[0021] All rectification columns (still pots) consisted of 2 inch diameter vacuum jacketed sections containing Sulzer BX wire m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap