Paper feeding box, printer and method for using paper feeding box

A technology for printing devices and paper feeding, which is applied in printing devices, printing, transportation, and packaging, and can solve the problems of increasing the number of overall components, increasing manufacturing complexity, and the inability to reduce the manufacturing cost of paper trays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are described below with reference to the drawings.

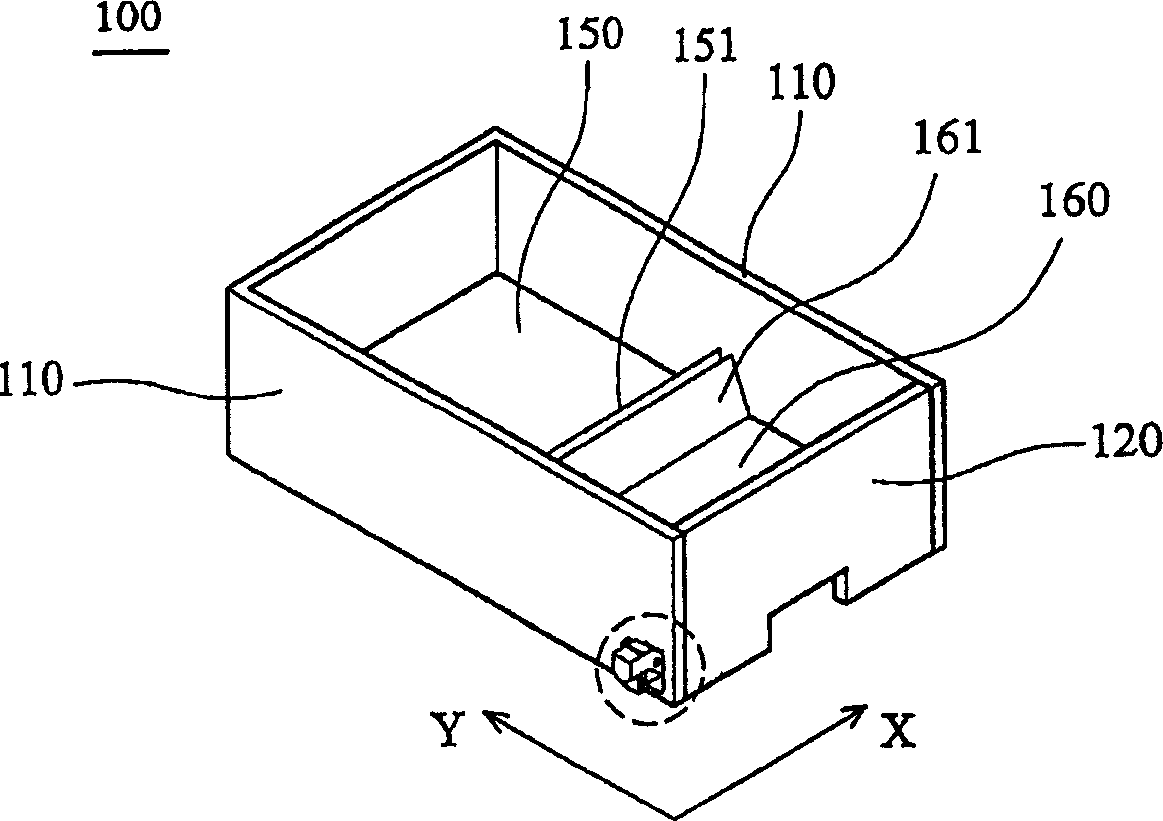

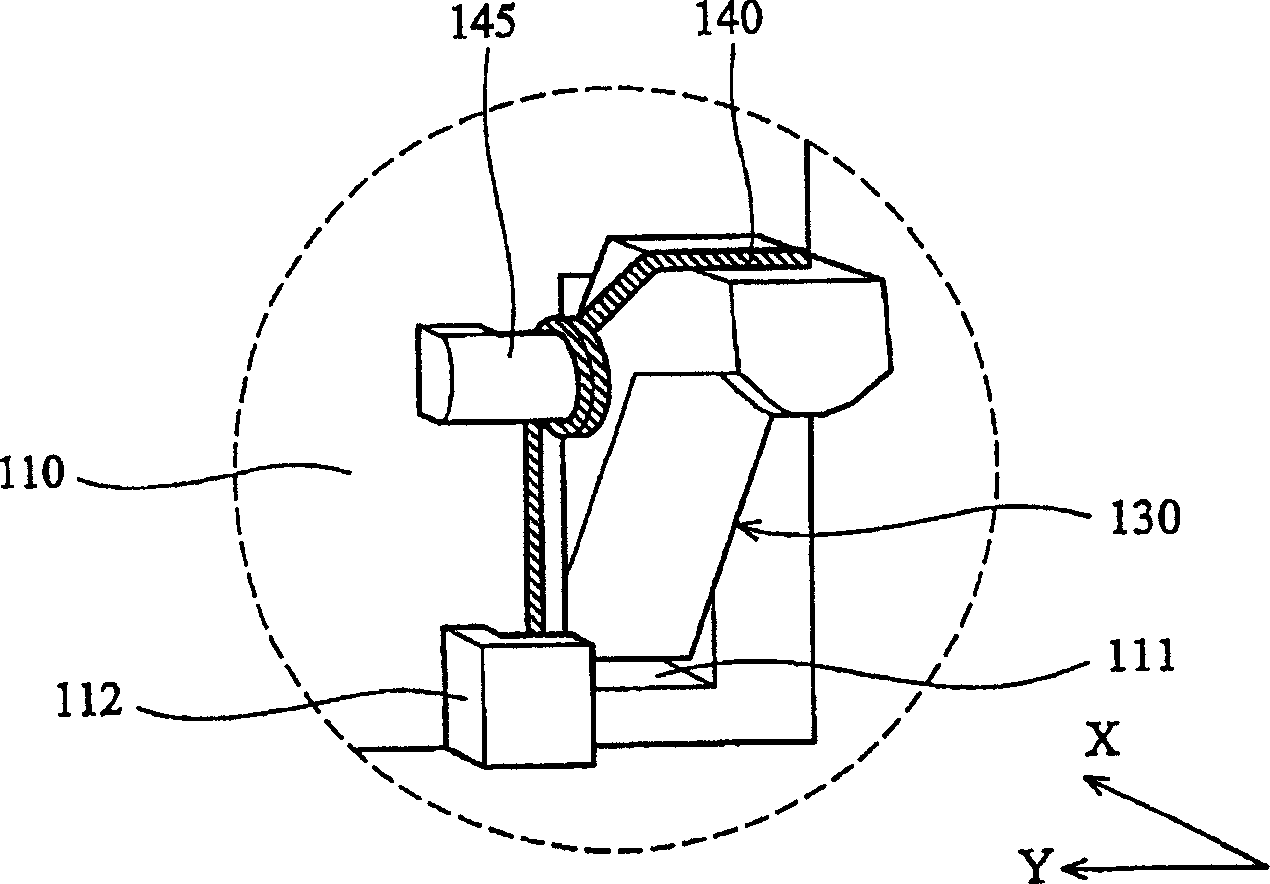

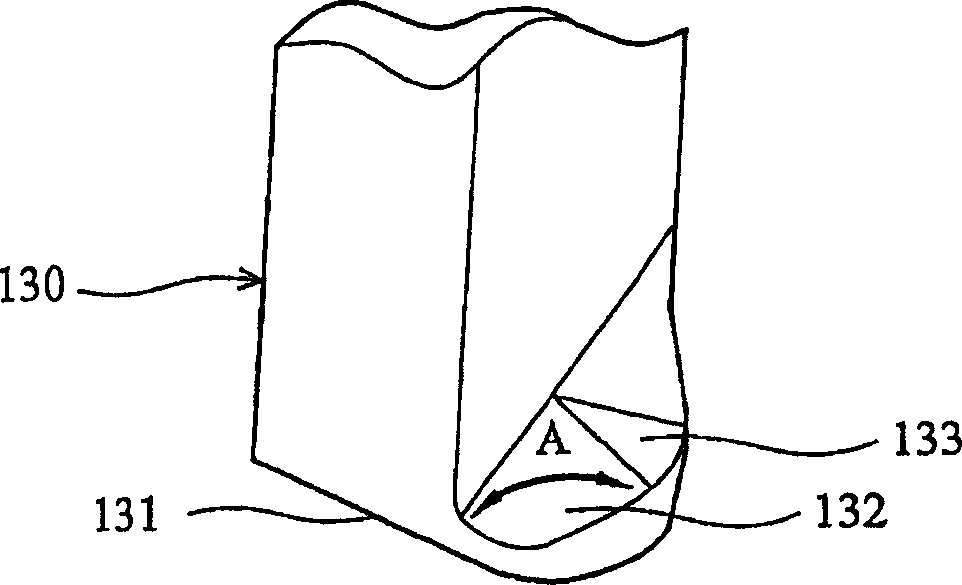

[0021] see figure 1 and figure 2 , the paper tray 100 of the present invention can be combined with a printing device (not shown), and it is mainly composed of two side walls 110, a door panel 120, a rotating assembly 130, an elastic assembly 140, a fixing pin 145, a main The paper tray part 150 and an auxiliary paper tray part 160 are formed.

[0022] Such as figure 1 As shown, the auxiliary paper tray part 160 is located between the main paper tray part 150 and the door panel 120 , and paper can be placed in the auxiliary paper tray part 160 and the main paper tray part 150 . In addition, the printing device also has a paper inlet (not shown), and the auxiliary paper tray part 160 and the main paper tray part 150 also have a paper output baffle 161 and a paper output baffle 151 respectively, the paper output baffle 161 and 151 are adjacent to each other. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com