an incinerator

A technology for incinerators and furnace bodies, applied in the field of incinerators, can solve problems such as insufficient working life, uneven incineration of incinerators, etc., and achieve the effect of increasing service life, improving efficiency, and uniform incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

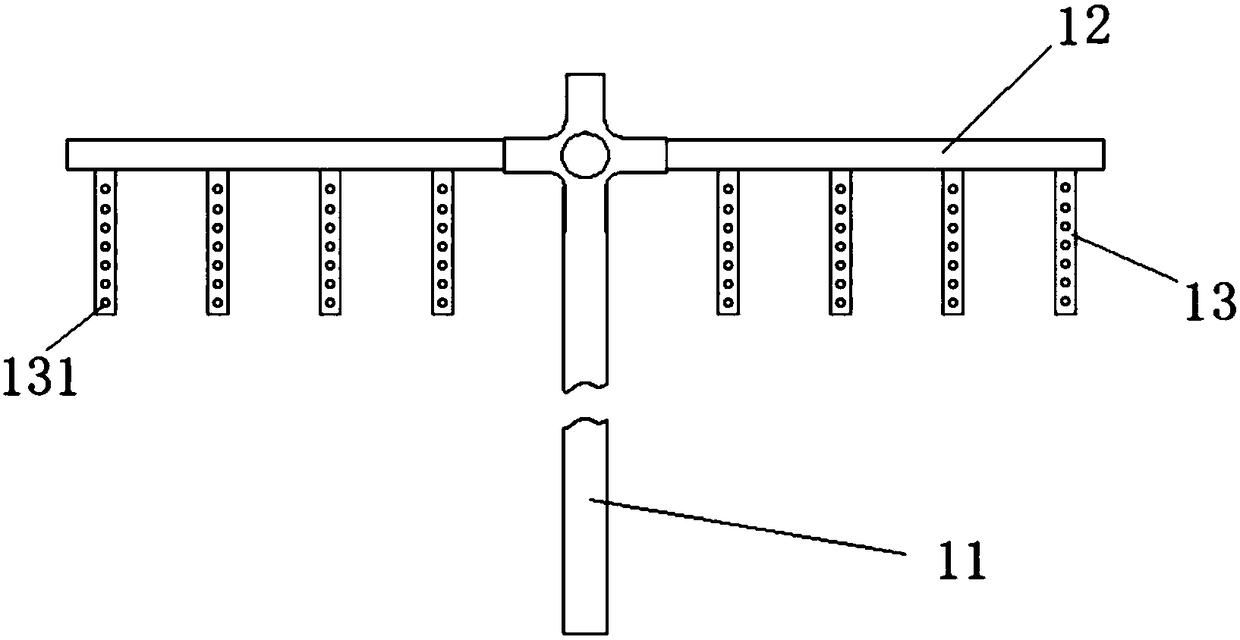

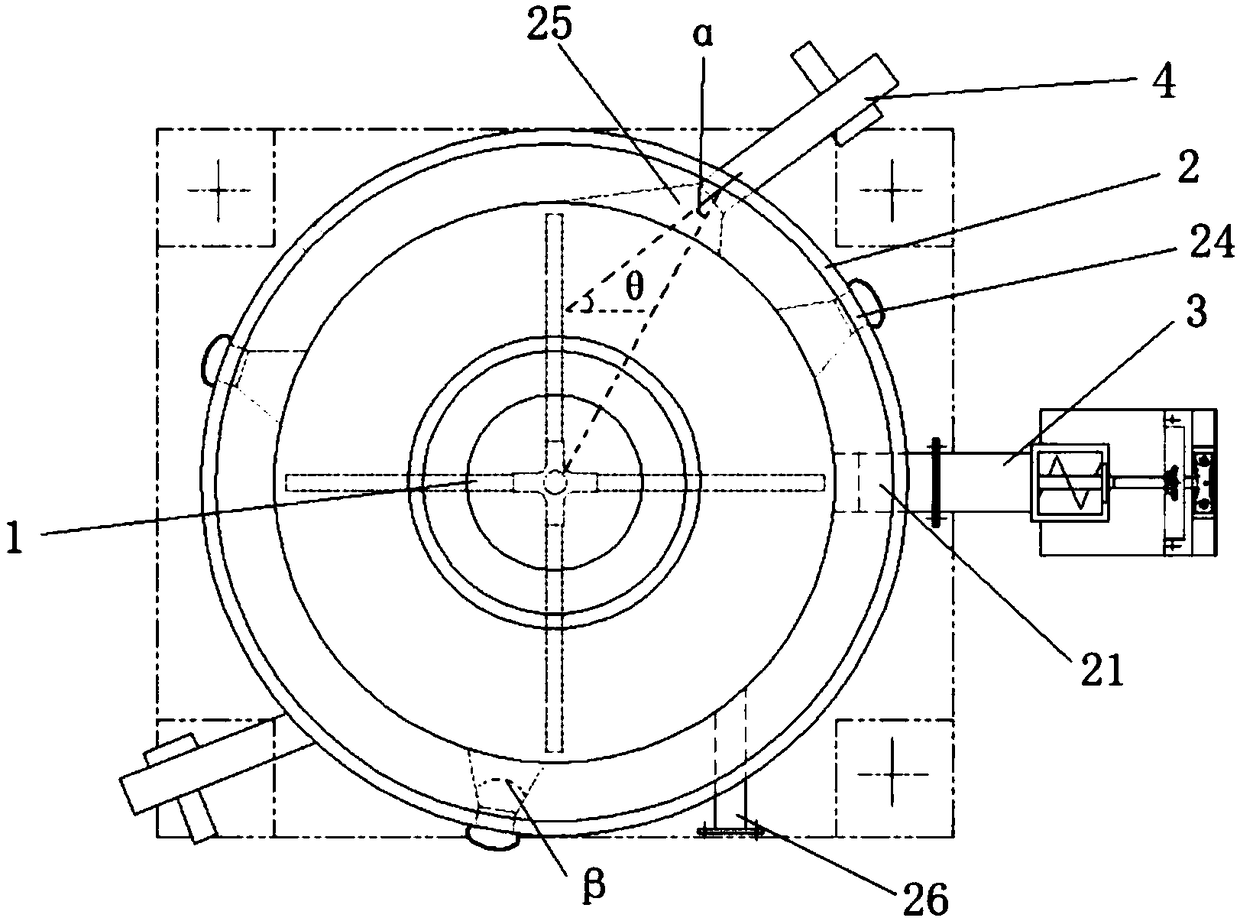

[0037] This embodiment provides an incinerator, such as figure 1 and 2 shown, including,

[0038] furnace body 2, such as figure 1 The bottom shown is cylindrical, the upper part is truncated circular, the side wall is provided with a feed inlet 21 and a high-temperature gas outlet 25, the top is provided with an air outlet 23, and the bottom is provided with a discharge outlet 22;

[0039] The burner 4 communicates with the high-temperature gas tuyeres 25 and is used for blowing high-temperature gas into the interior of the furnace body 2;

[0040] Stirring device for stirring the materials in the furnace body 2;

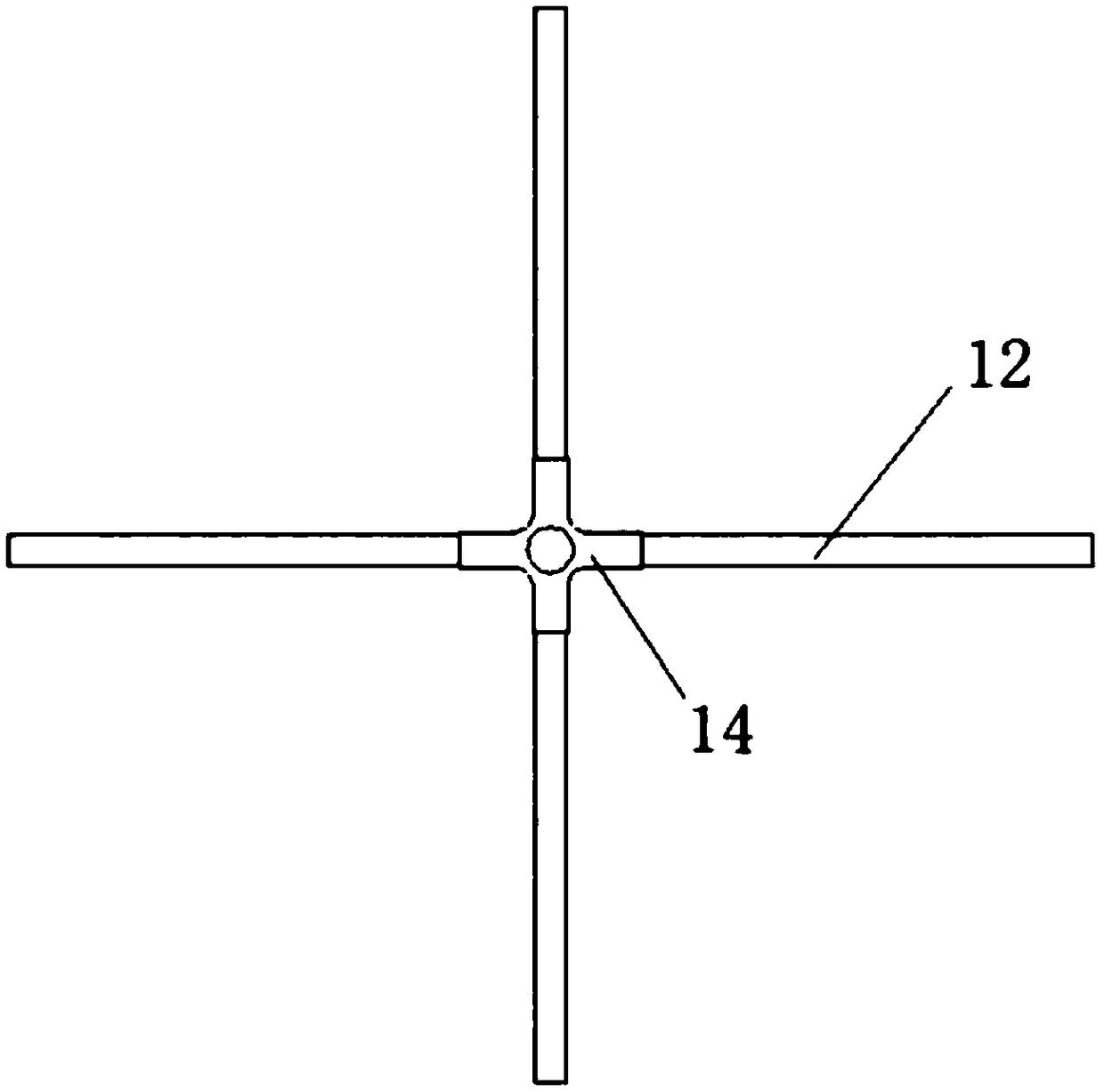

[0041] The stirring device includes a rotating shaft 11, which extends vertically from the outside of the furnace body 2 through the bottom wall of the furnace body 2 into the inside of the furnace body 2, and is hollow inside, driven by a power device to be able to rotate;

[0042] The horizontal tube 12 is arranged on the rotating shaft 11, arranged horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com