Firecracker and production method

A production method and technology for firecrackers, which can be used in firecrackers, fireworks, offensive equipment, etc., can solve the problems of easy explosion accidents and low safety, and achieve the advantages of reducing the possibility of explosion accidents, improving safety, and enhancing fracture resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

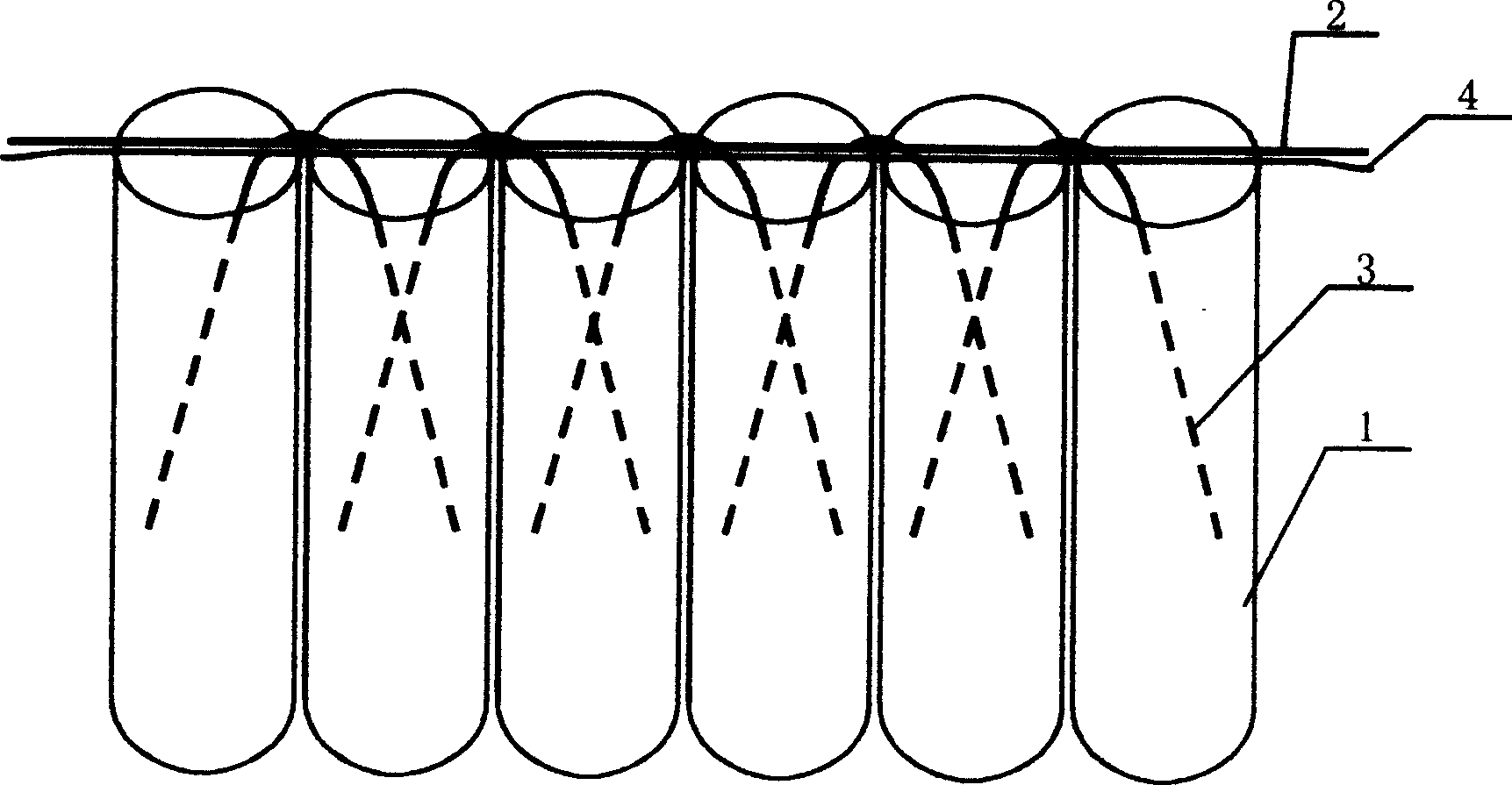

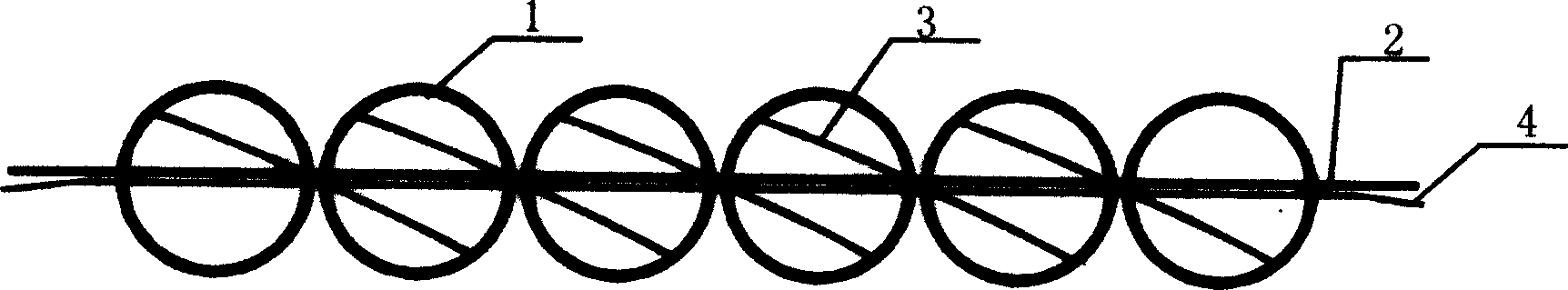

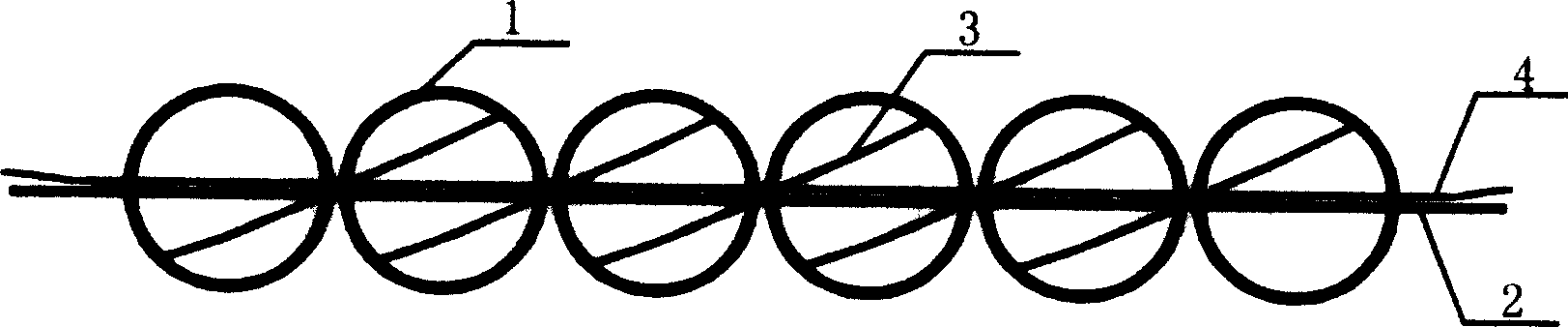

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] combine figure 1 , figure 2 with image 3 , the two ends of the firecracker tube fuse 3 of firecrackers in the present invention are respectively located in two adjacent firecracker tubes 1, the middle section of the firecracker tube fuse 3 is pressed on the female fuse 2, and the two ends of the firecracker tube fuse 3 are respectively located in the female fuse 2 Two sections of firecracker tube fuses 3 in each firecracker tube 1 except the first and last two firecracker tubes 1 are positioned at the both sides of mother fuse 2 respectively.

[0021] Because the firecracker tube 1, the firecracker tube fuse 3 and the female fuse 2 can be connected only by inserting the two ends of the firecracker tube fuse 3 into two adjacent firecracker tubes 1 respectively, so this procedure is simple and fast; Each firecracker tube 1 outside the first and last two firecracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com