Optical semiconductor device and optical semiconductor integrated circuit

A semiconductor and optical waveguide technology, applied in the field of optical semiconductor components and optical semiconductor integrated circuits, can solve the problems of the limitation of the degree of freedom of the waveguide, the inability to use cleavage surfaces, and the difficulty in manufacturing, so as to improve the degree of freedom, suppress the deterioration of reliability, Effect of suppressing waveguide loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

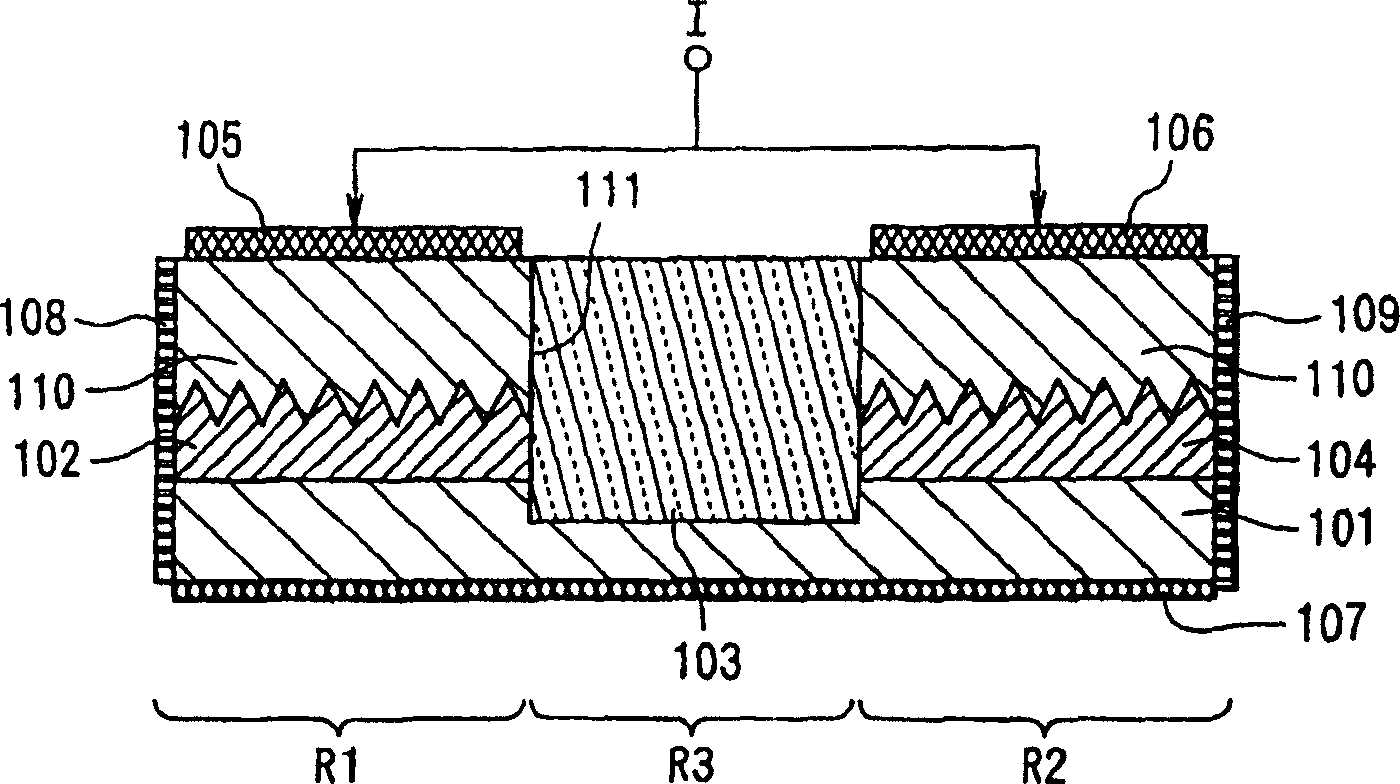

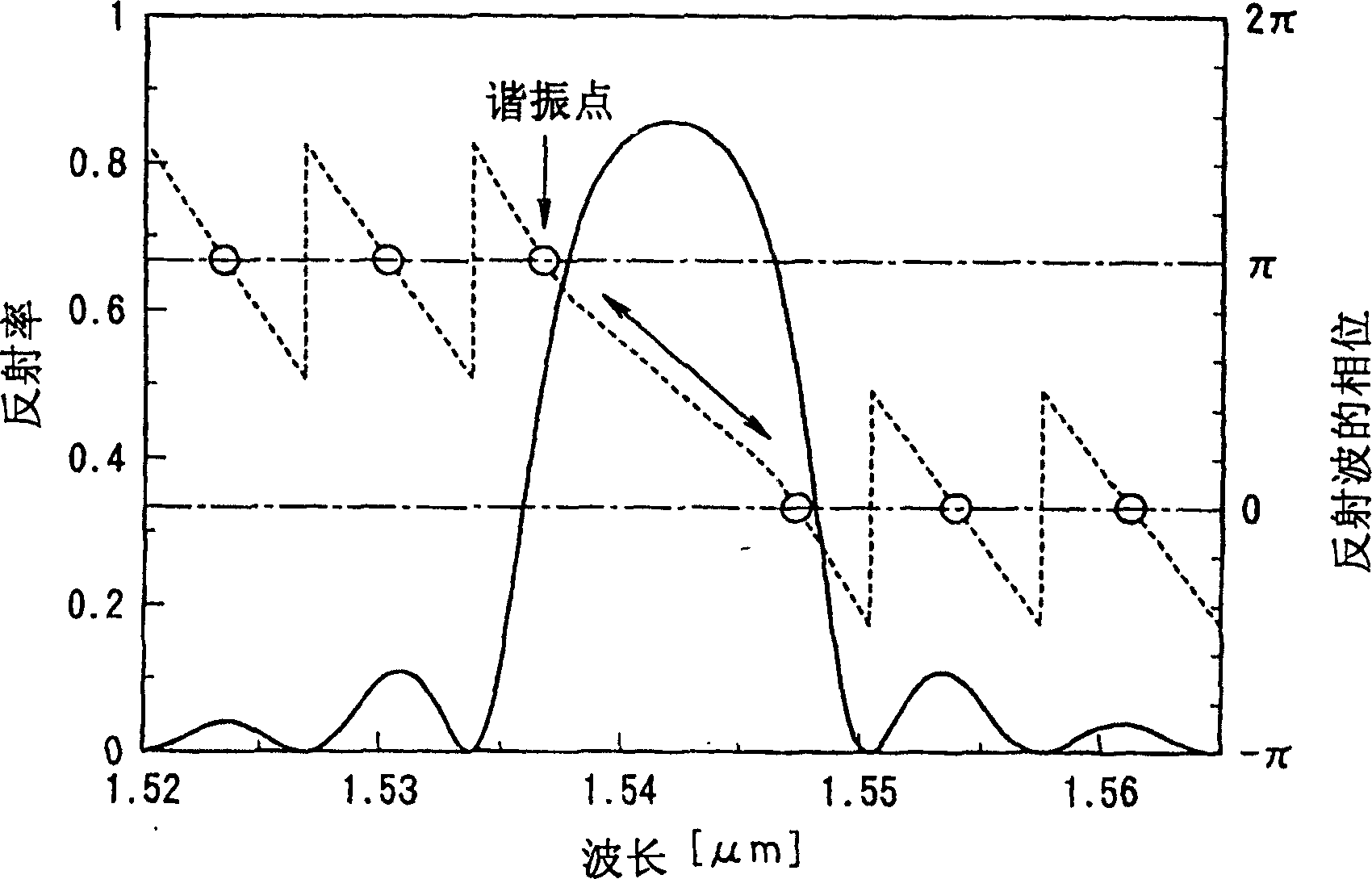

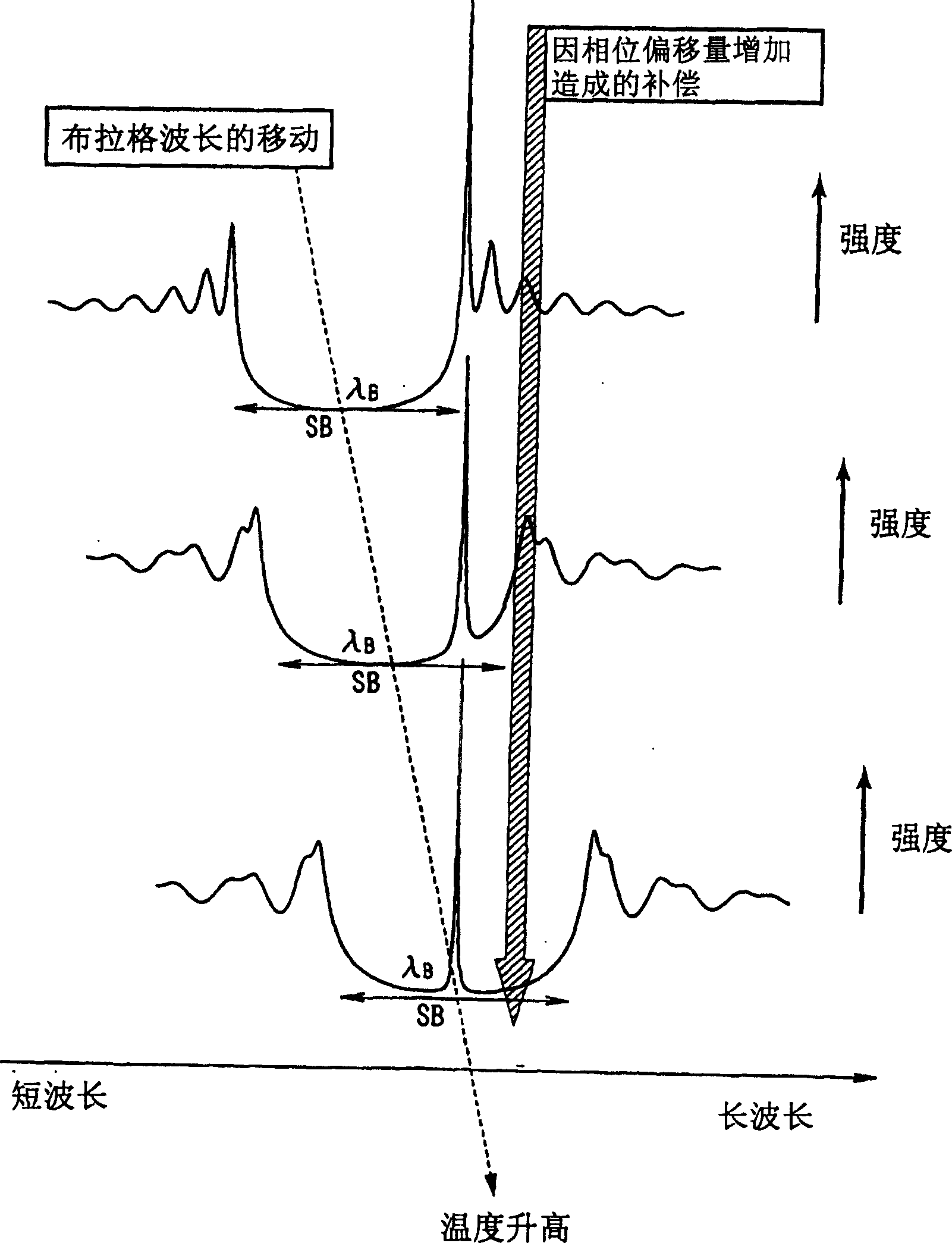

[0090] Several embodiments of the present invention will be described below with reference to the drawings. First, as a first embodiment, some examples of application examples to semiconductor lasers will be shown and described. In this embodiment mode, by combining a semiconductor laser with a material having a different temperature dependence of the refractive index, it is possible to control the temperature dependence of the vibration wavelength of the semiconductor laser.

[0091] As a second embodiment, some examples of application to integrated optical waveguides will be shown and described. In this embodiment, when integrating a semiconductor optical waveguide with an optical waveguide having a different refractive index and a temperature dependence of the refractive index, reflection at the interface between these optical waveguides can be reduced. In addition, by integrating a semiconductor optical waveguide with an optical waveguide having a different refractive ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com