Gas turbine combustor, and gas turbine with the combustor

A gas turbine and burner technology, which is applied in gas turbine installations, machines/engines, combustion chambers, etc., can solve problems such as combustion vibration that cannot be completely solved at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

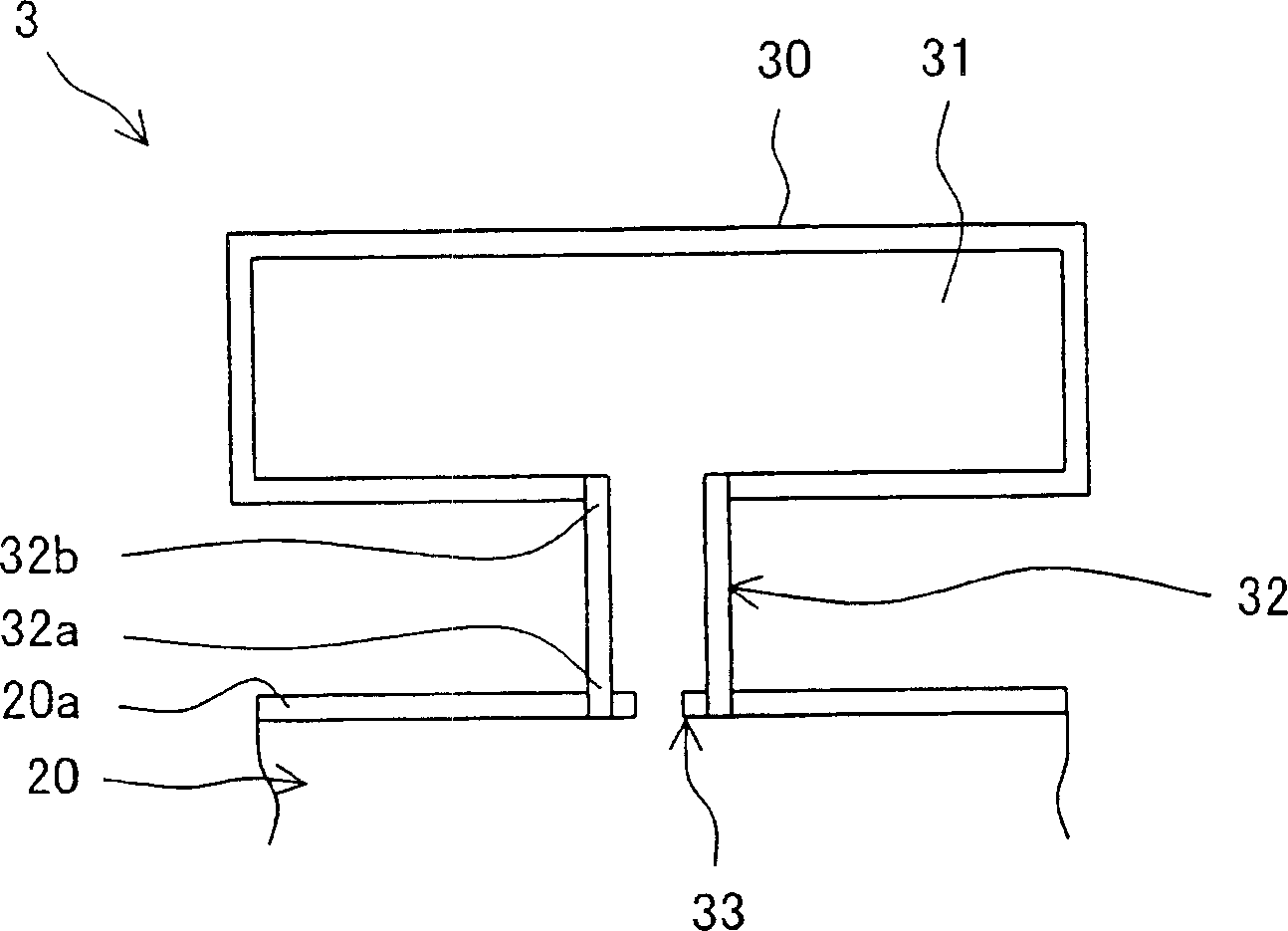

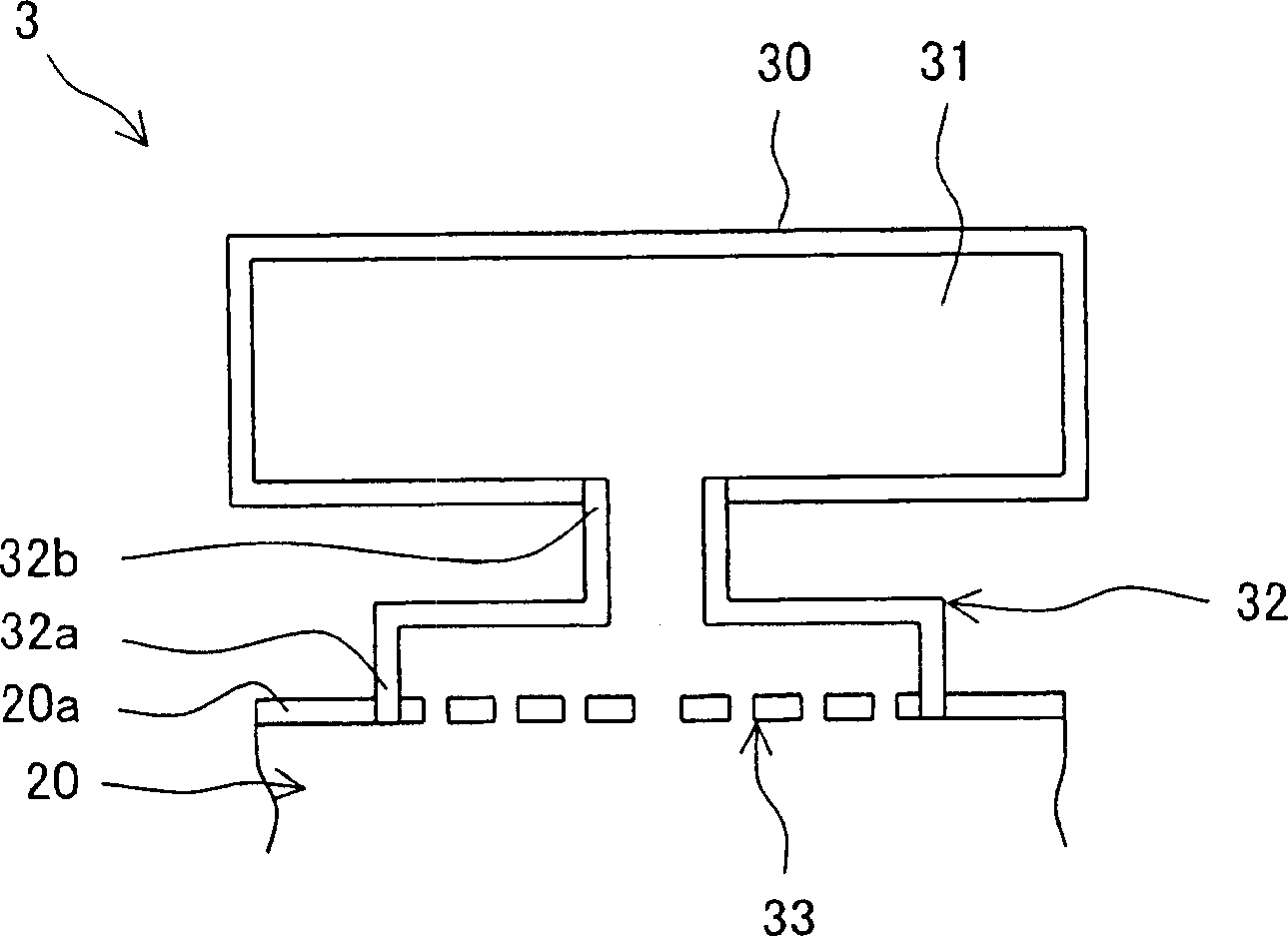

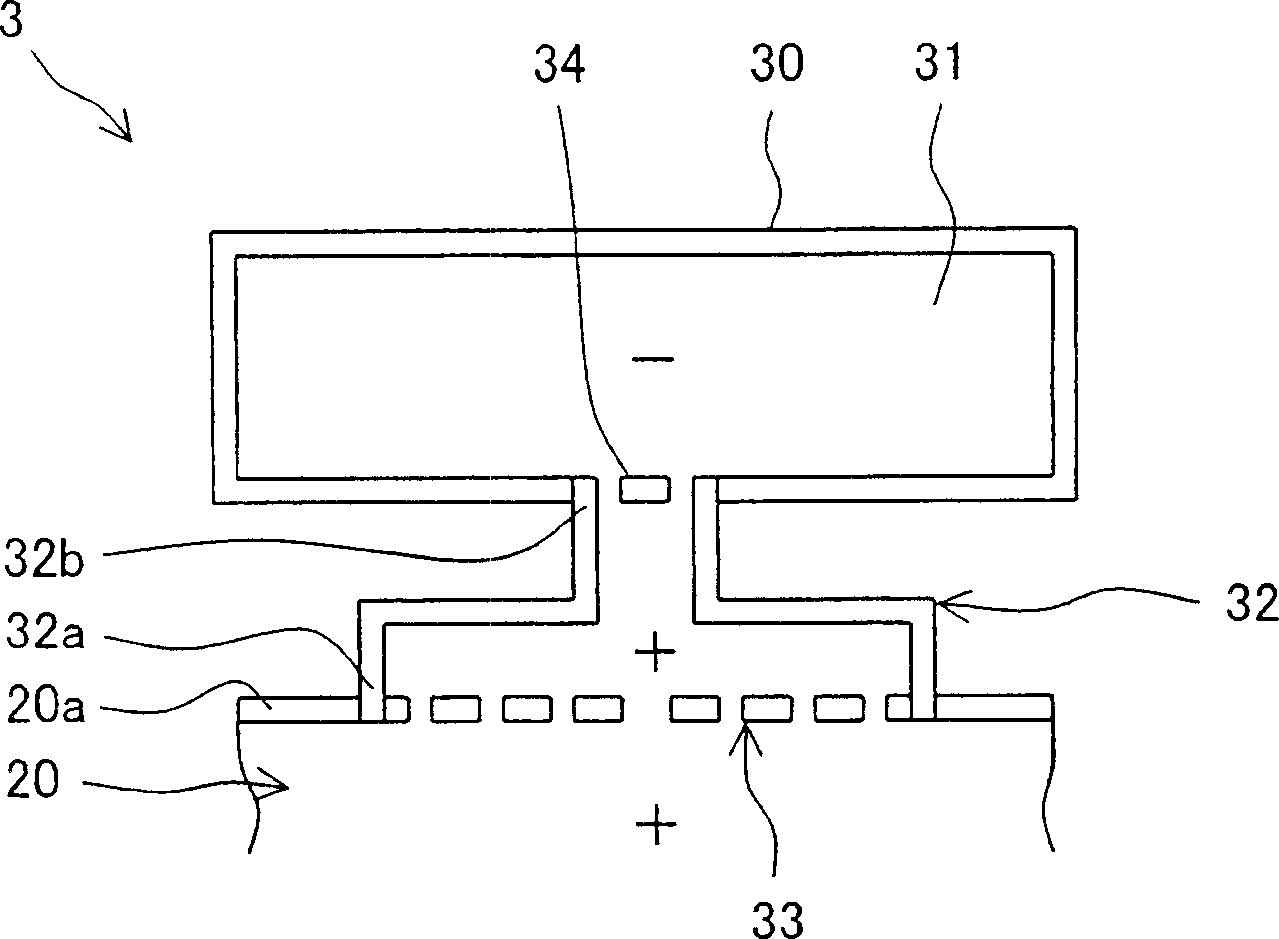

[0066] Now, embodiments of the present invention will be described below with reference to the drawings. First, the first to eighth embodiments of the present invention will be described page by page. figure 1 It is a cross-sectional view showing the configuration of the burner according to the first embodiment of the present invention. In the figure, the same mark means that it has Figure 47 For the parts with the same name and the same function, the same explanation will be omitted. The same applies to the second to eighth embodiments of the present invention which will be described below.

[0067] The burner 3 according to the first embodiment of the present invention is applied to Figure 47 Gas turbine 1 shown in. Such as figure 1 As shown in the figure, a first box 30 is installed outside the side wall 20a of the target body 20, and a first internal space 31 having a predetermined volume is formed by a cavity inside the first box 30. In addition, the first box body 30 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com