Adaptive intake system of diesel engine

An air intake system, self-adaptive technology, applied in the direction of charging system, fuel air intake, mechanical equipment, etc., can solve the problems of reducing combustion vibration, low compressed air temperature, shortening the ignition delay period, etc., to reduce combustion vibration , the effect of large supercharging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

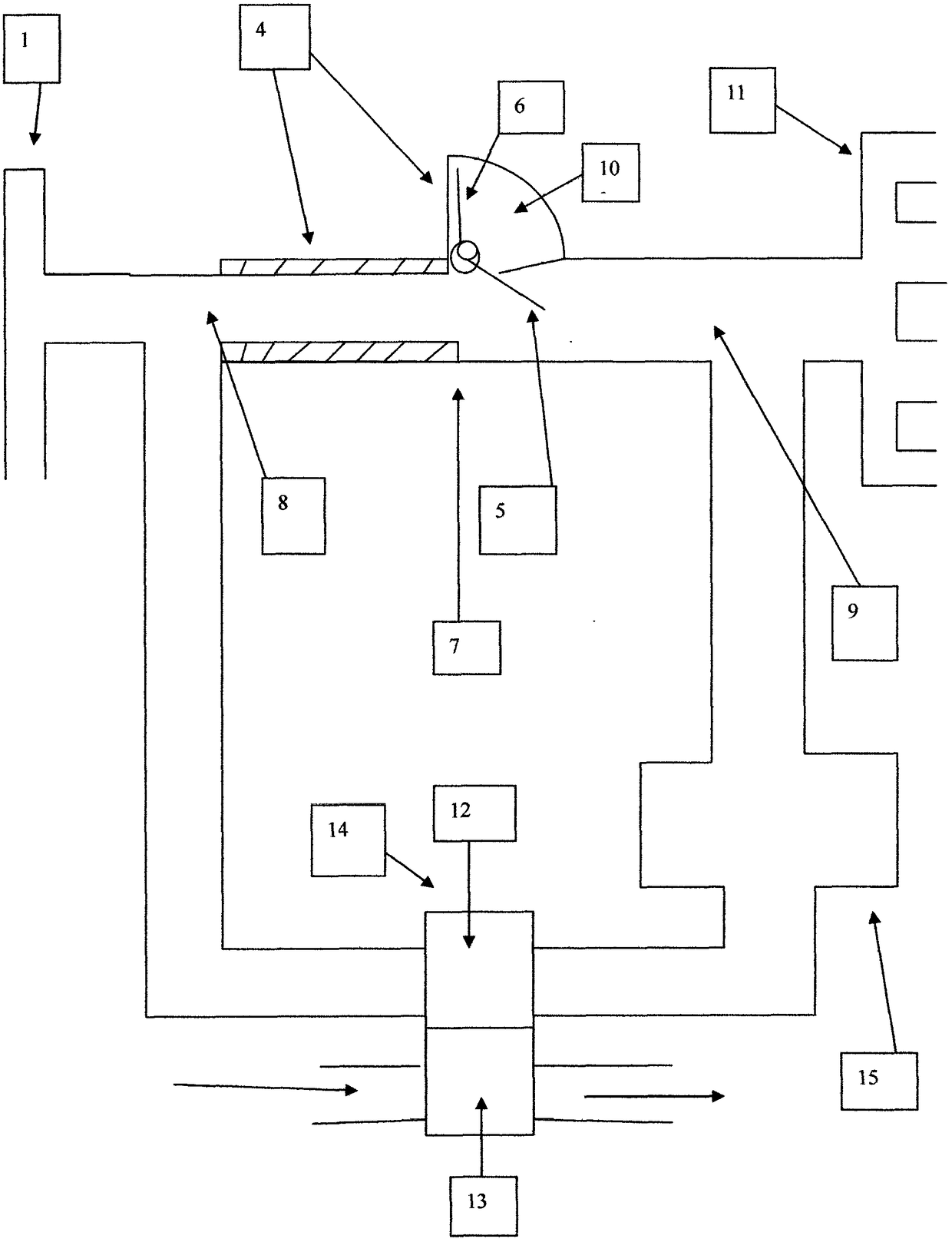

[0009] exist figure 1 Among them, the air outlet of the air filter assembly (1) is connected to the air inlet (8) of the air intake check valve (4) and the inlet of the intake turbine (12) of the exhaust gas turbocharger assembly (14). The air port is connected, the air outlet of the intake turbine (12) of the exhaust gas turbocharger assembly (14) is connected with the air inlet of the intercooler (15), and the air outlet of the intercooler (15) and the air intake are unidirectional The air outlet (9) of the valve (4) communicates with the air inlet of the intake manifold (11).

[0010] When the exhaust gas turbocharger engine is starting and at a low speed, the impact energy of the exhaust gas turbine (13) of the exhaust gas turbocharger assembly (14) due to the engine exhaust gas is not enough to make the exhaust gas turbocharger assembly (14) The intake turbine (12) produces a supercharging effect, and the air inhaled by the engine can enter the cylinder after passing thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com