On-line weighing dispensing method based on feed speed control

A technology of feeding speed and control amount, applied in the direction of ratio control, non-electric variable control, control/regulation system, etc., can solve the problems of different feeding speeds, large restrictions on batching accuracy, and difficult control of weighing accuracy, etc., to achieve Reliable consistency, avoiding the influence of human factors, and the effect of easy weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

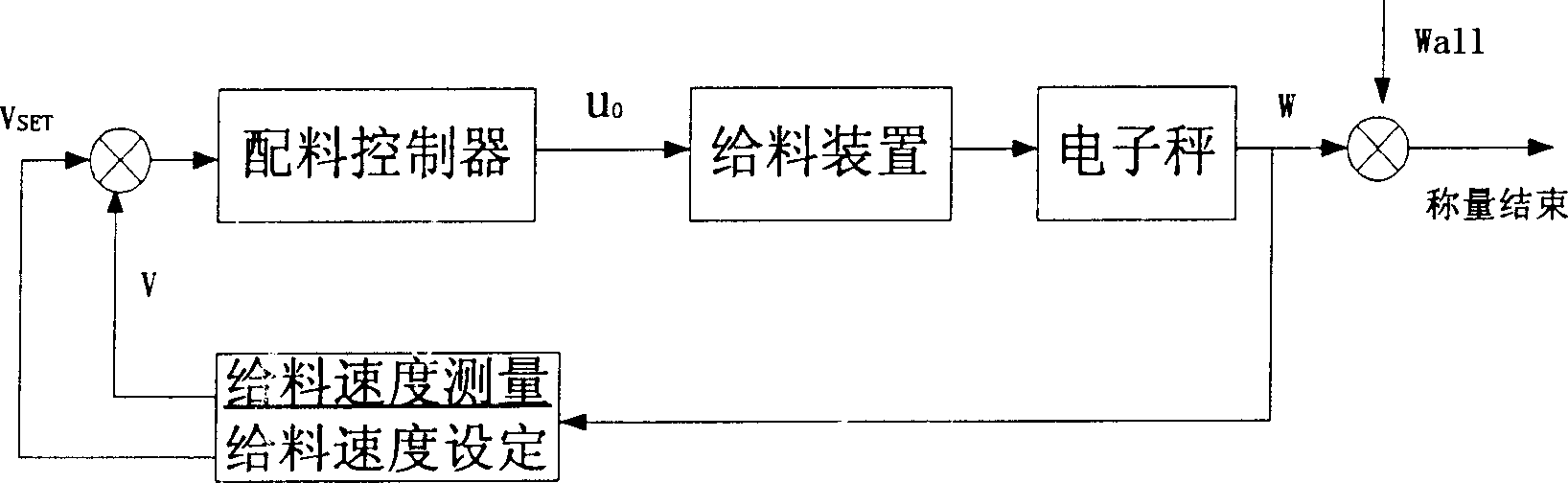

[0053] Example 1, such as figure 1 As shown, applying the online weighing and batching method based on feeding speed control, the feeding device is equipped with a batching controller to realize the setting and measurement of the control feeding speed, and the material weight actually measured by the weighing device To reversely control the running speed or vibration frequency of the feeding device.

[0054] Under the control of the online weighing and batching method, the weight accuracy of the material to be weighed is realized based on the control of the feeding speed, that is, the control of the operating speed of the feeding equipment.

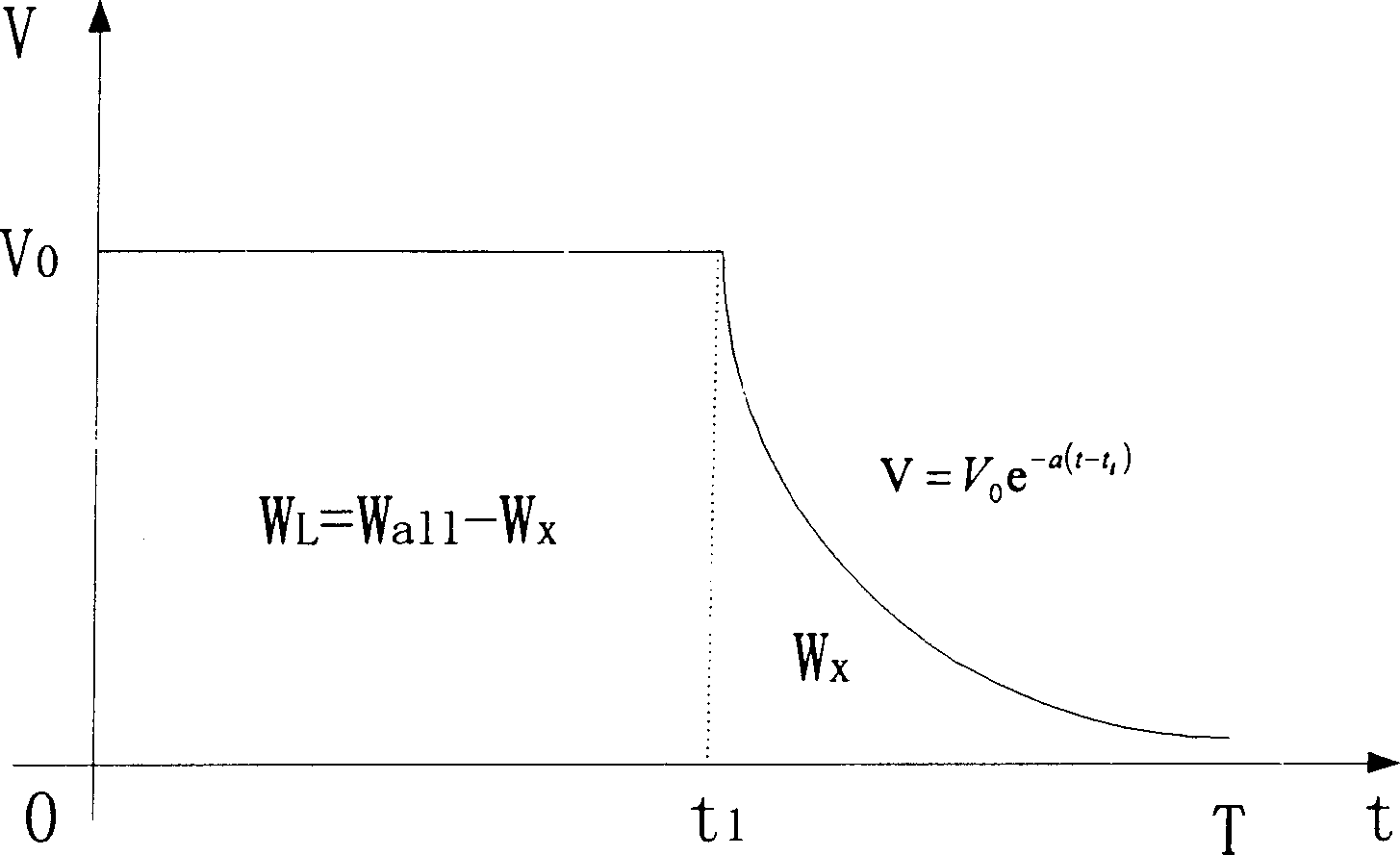

[0055] Such as Figure 1 to Figure 3 Shown, described online weighing batching method is:

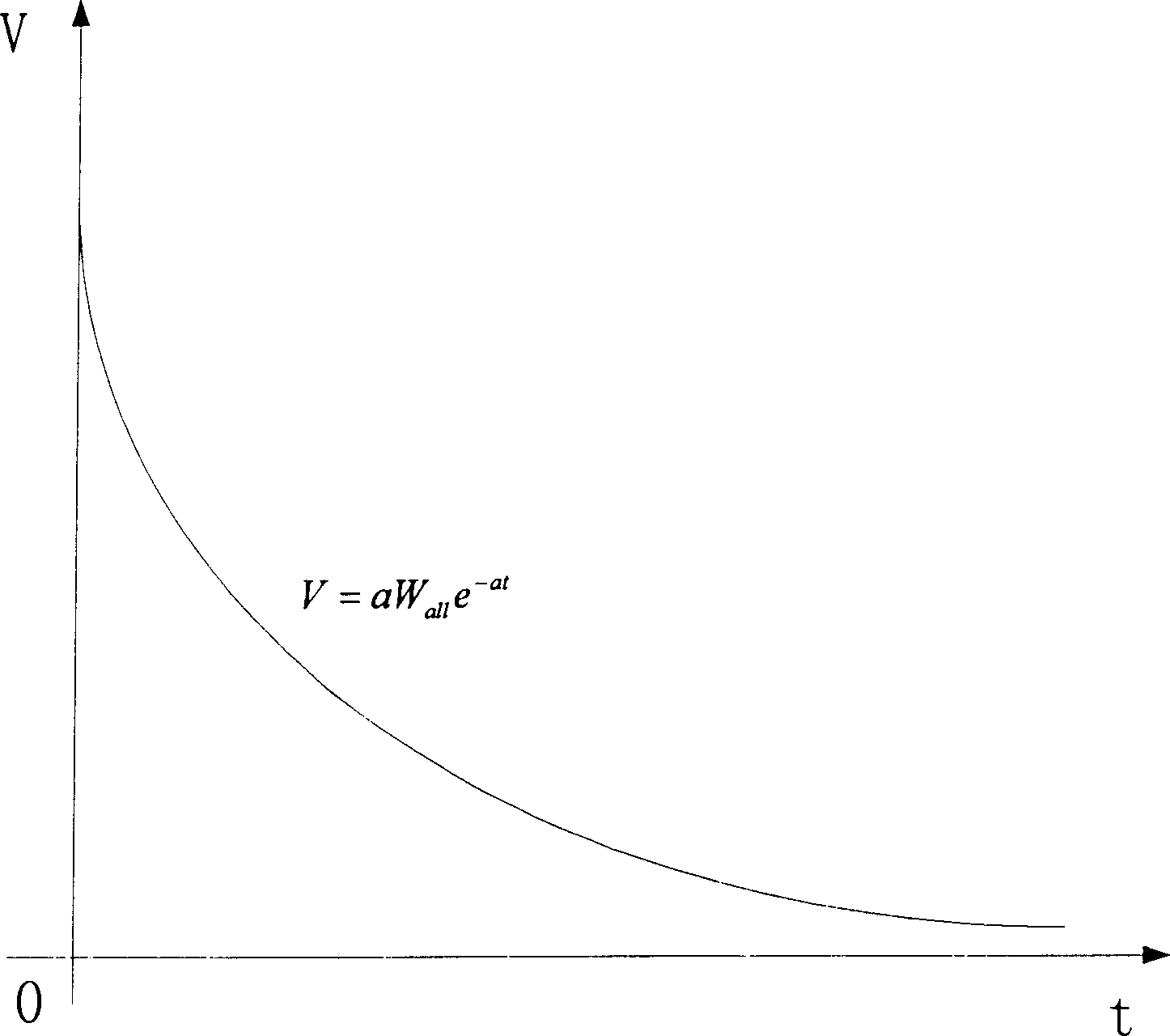

[0056] The first step is to establish the weighed material W all , The functional relationship between the feeding speed V and the weighing time T. That is, select any material to be weighed after the described feeding device and its control de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com