Lifting device of dyeing mechanism for flat screen printing machine

A screen printing machine and lifting device technology, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve problems such as large difference in rebound force, difficulty in obtaining rebound force, difficulty in responding flexibly and quickly, and achieve Effects of smooth lifting operation and smooth motion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

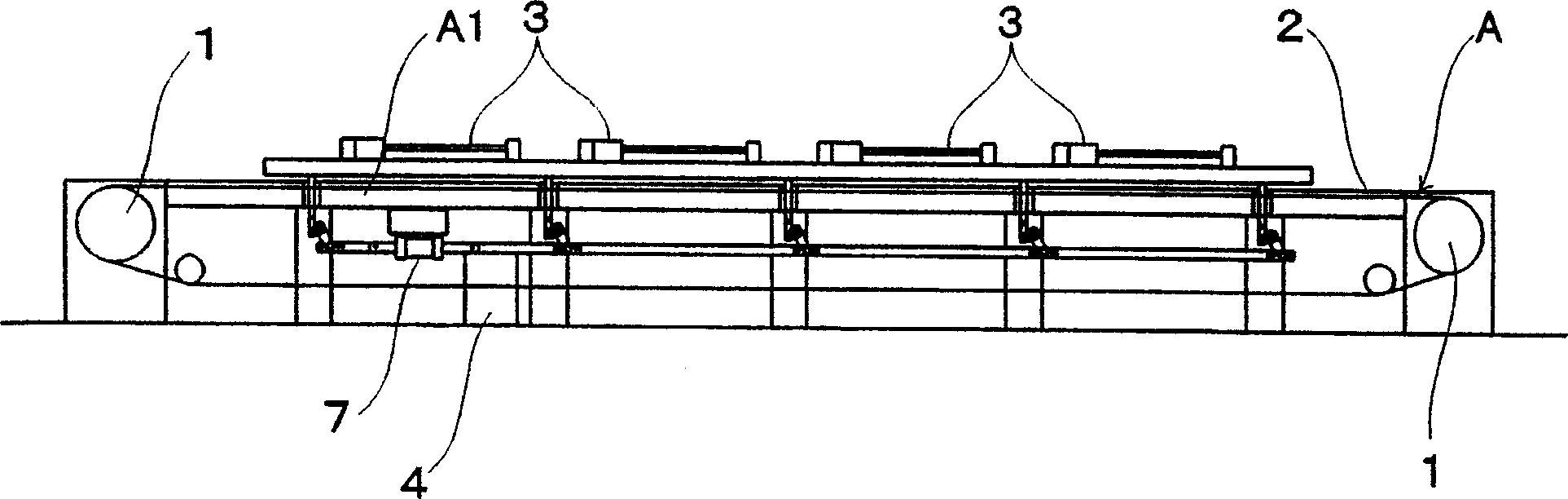

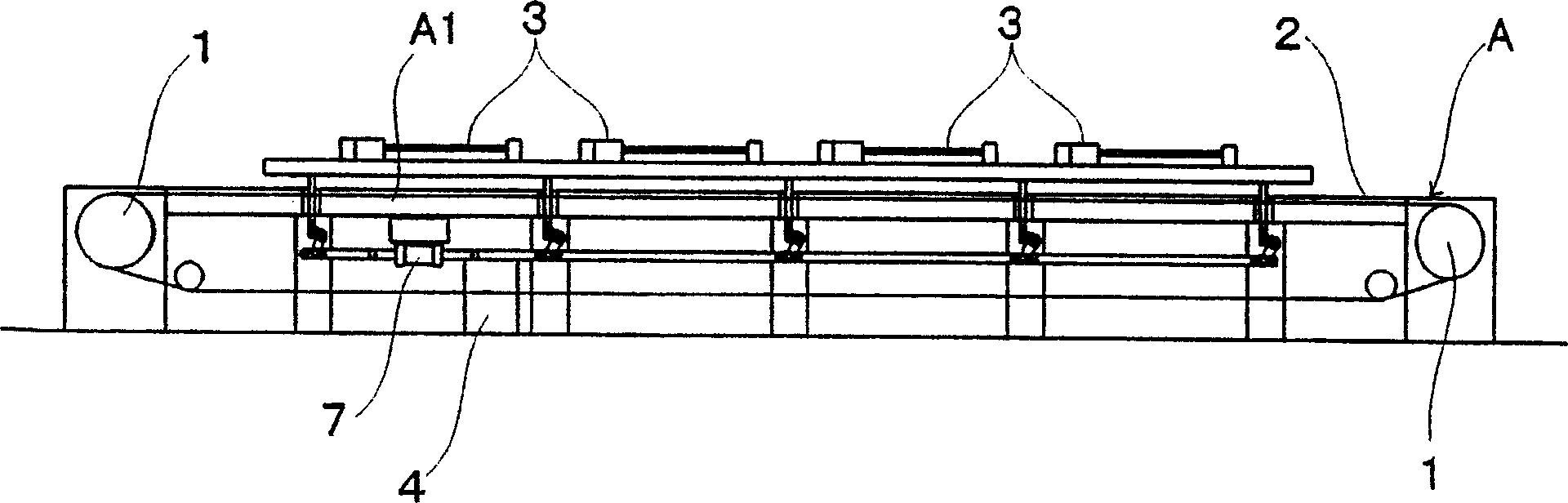

[0019] Such as figure 1 and figure 2 As shown, the flat screen printing machine has: an endless belt 2 erected between pulleys 1 in order to convey cloth and other printed objects, a printing and dyeing mechanism 3 with a screen frame, a printing and dyeing mechanism lifting device 4, and a control mechanism for controlling them ( illustration omitted).

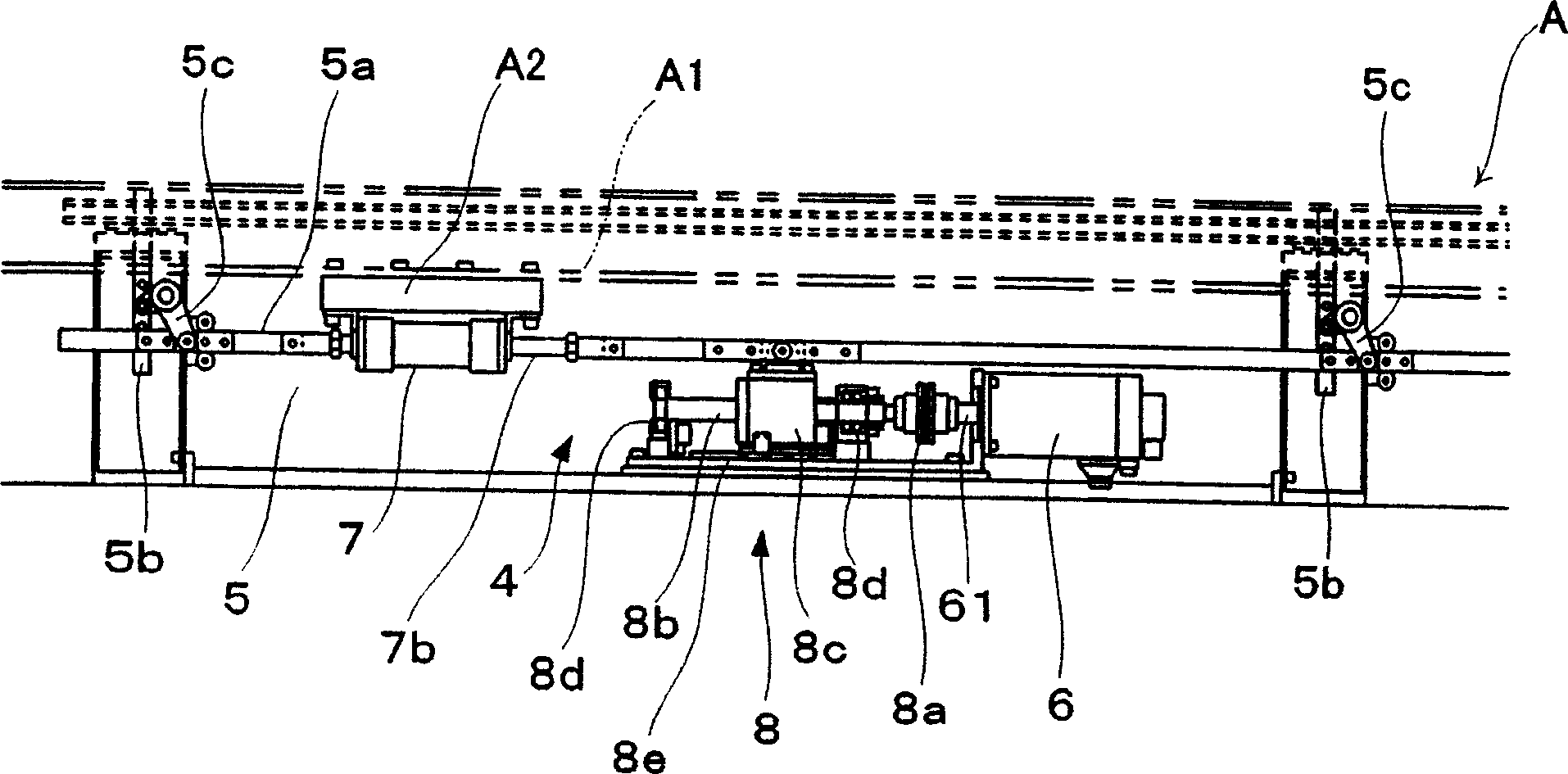

[0020] Such as image 3 As shown, the printing and dyeing mechanism lifting device 4 includes: a lifting mechanism part 5, a servo motor (drive source) 6, and a power auxiliary mechanism 7 for assisting the driving force of the servo motor 6 for lifting the printing and dyeing mechanism 3, which are respectively arranged on the endless belt. 2 on both sides of the circular direction. in addition, figure 2 Indicates the state of raising the printing and dyeing mechanism 3, figure 1 Indicates the state in which the printing and dyeing mechanism 3 is lowered.

[0021] The elevating mechanism unit 5 includes: an operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com