Cool heat exchanger having oscillation reducing structure

A vibration-damping structure and switch technology, which is applied to refrigerators, irreversible cycle compressors, compressors, etc., can solve the problems of reduced service life of cold and heat exchangers, accelerated refrigerant leakage speed, and reduced service life of cold and heat exchangers, etc., to achieve Excellent sealing performance and obvious shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Since the refrigeration principles of refrigerators and air conditioners (including) are roughly equivalent, and air conditioners or air conditioners with dual-purpose heating and cooling usually only use four-way valve 7 and other components to change the circulation direction of refrigerant when heating. Therefore, the above products are implemented There is no essential difference between the design concepts of the present invention, so they can be collectively referred to as cooling and heat exchangers in illustrations and specific descriptions.

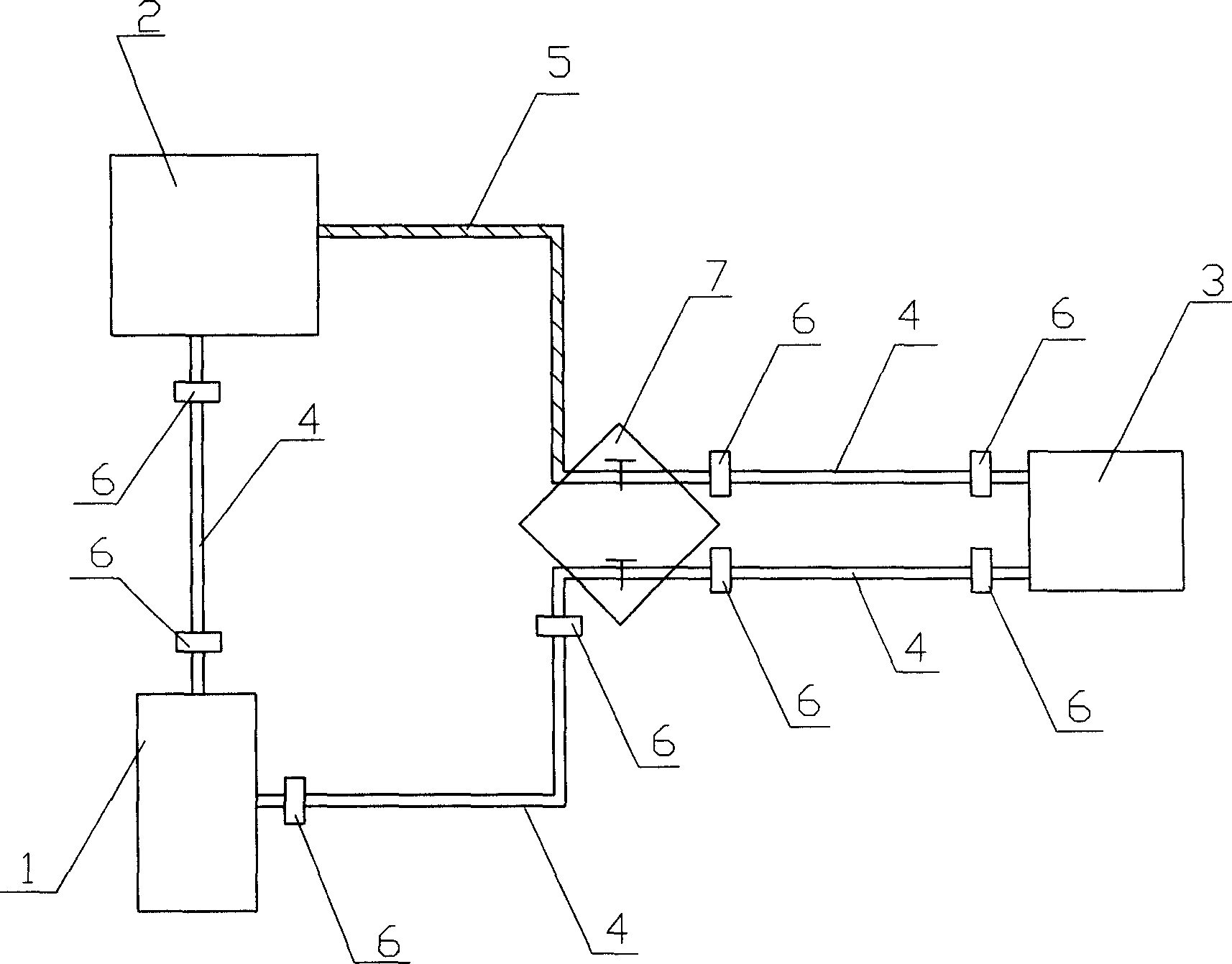

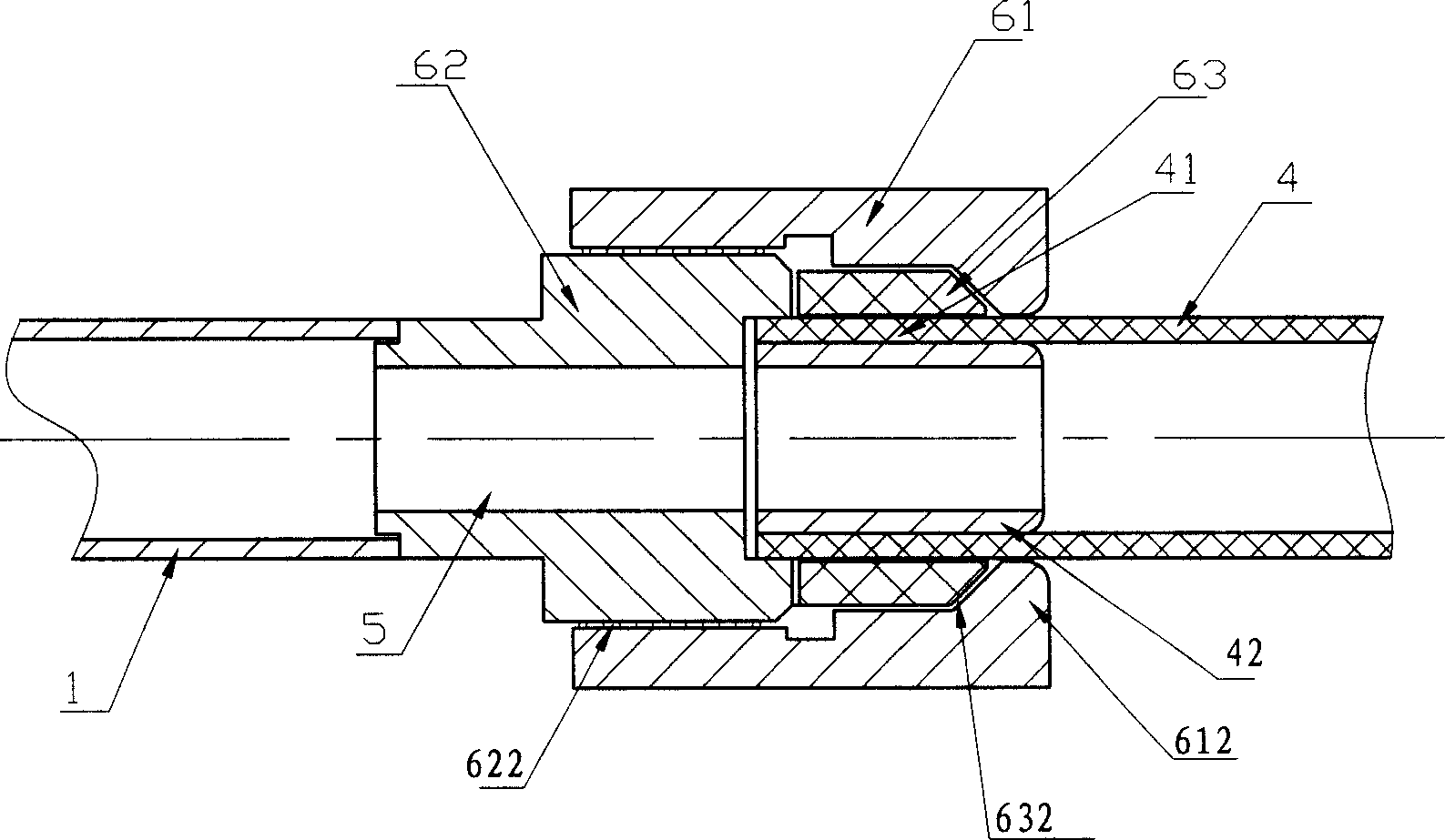

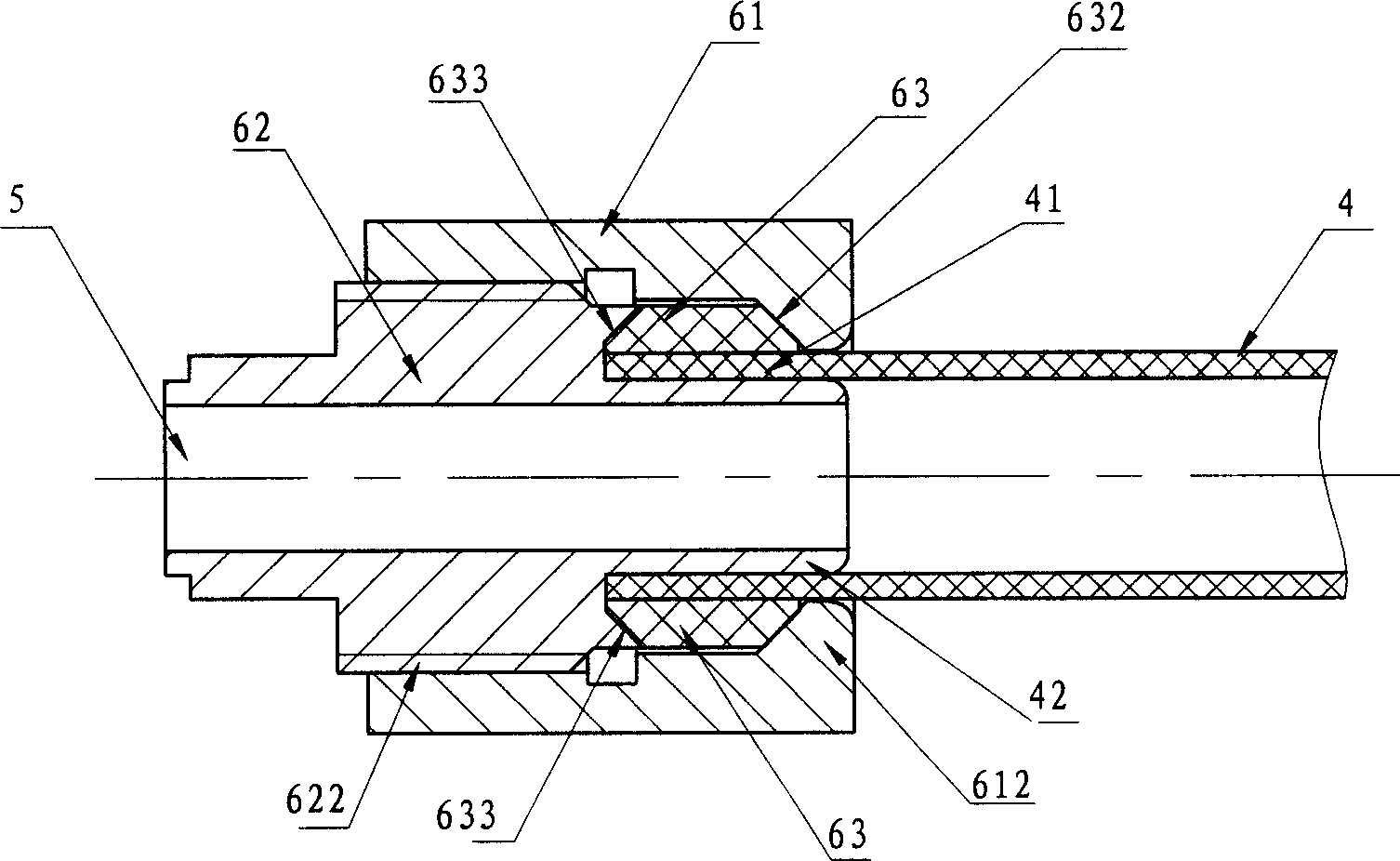

[0015] The technical embodiment of the present invention is specifically set forth below by taking a common air conditioner as an example, with reference to figure 1 with figure 2 , including compressor 1, condenser 2, and evaporator 3 and other refrigeration components; and a plurality of pipelines for communicating with the aforementioned compressor 1, condenser 2, evaporator 3, etc. Carry out the circulating loop of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com