A high-strength three-layer co-extruded lithium-ion battery separator and preparation method thereof

A lithium-ion battery, three-layer co-extrusion technology, applied in the direction of secondary batteries, battery components, circuits, etc., to achieve the effect of improving the strength of the diaphragm, enhancing safety, and improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

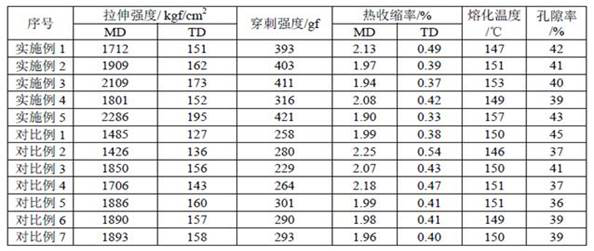

Examples

preparation example Construction

[0033] In parts by weight, the components of the B layer include 90-99 parts of homopolypropylene and 1-10 parts of lubricating nucleating particles, and the melt index of the homopolypropylene at 230° C. is 1-5 g / 10min , the isotacticity is not less than 98%; the preparation method of the lubricating nucleating particles includes the following steps: A) mixing polytetrafluoroethylene micropowder and pimelic acid for ball milling; the ball milling medium is ethanol, and the ball milling time is 1~3h B) add calcium stearate, continue ball milling for 0.5~1h; after the ball milling finishes, the obtained product is washed and dried to obtain the lubricating nucleating particles; wherein, the added polytetrafluoroethylene micropowder, pimelic acid and stearic acid The mass ratio of calcium is 5~10:1:1~2; the ball milling temperature in steps A) and B) is -20~-10°C, the mass ratio of the material balls added during ball milling is 1:10~30, and the polytetrafluoroethylene The mass-vo...

Embodiment 1

[0043] A high-strength three-layer co-extruded lithium ion battery separator, comprising a B layer and an A layer arranged on both sides of the B layer; the total thickness of the separator is 16 μm, wherein the thickness of the B layer is 14 μm, and the thickness of the A layer is 1 μm;

[0044] The component of layer A is copolymerized polypropylene (Daihan Oil & Gas CB5230, its melt index at 230°C is 30g / 10min, and its rigidity modulus is 18000 kgf / cm 2 , the heat distortion temperature is 135 °C); in parts by weight, the components of the B layer include 90 parts of homopolypropylene (Korean Oil Chemical S801, its melt index at 230 °C is 3.0 g / 10min, isotactic 98%) and 5 parts of lubricating nucleating particles;

[0045] Wherein, the preparation method of lubricating nucleating particles includes the following steps: A) Mixing polytetrafluoroethylene micropowder (DuPont MP1300, USA) and pimelic acid in a high-energy ball mill for ball milling; the ball milling medium is e...

Embodiment 2

[0055] The difference between Example 2 and Example 1 is: in parts by weight, the components of layer A include 99 parts of copolymerized polypropylene (Korean Oil Chemical CB5230) and 1 part of calcium sulfate whisker (Weduofeng Biotechnology), and the rest are The same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com