Manuscript pressing plate switch

A technology of original pressing plate and switch device, which is applied in printing device, electrography, optics, etc. It can solve the problems of difficult maintenance work, pinching of hands and arms, difficult assembly operation, etc., and achieves the effect of compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

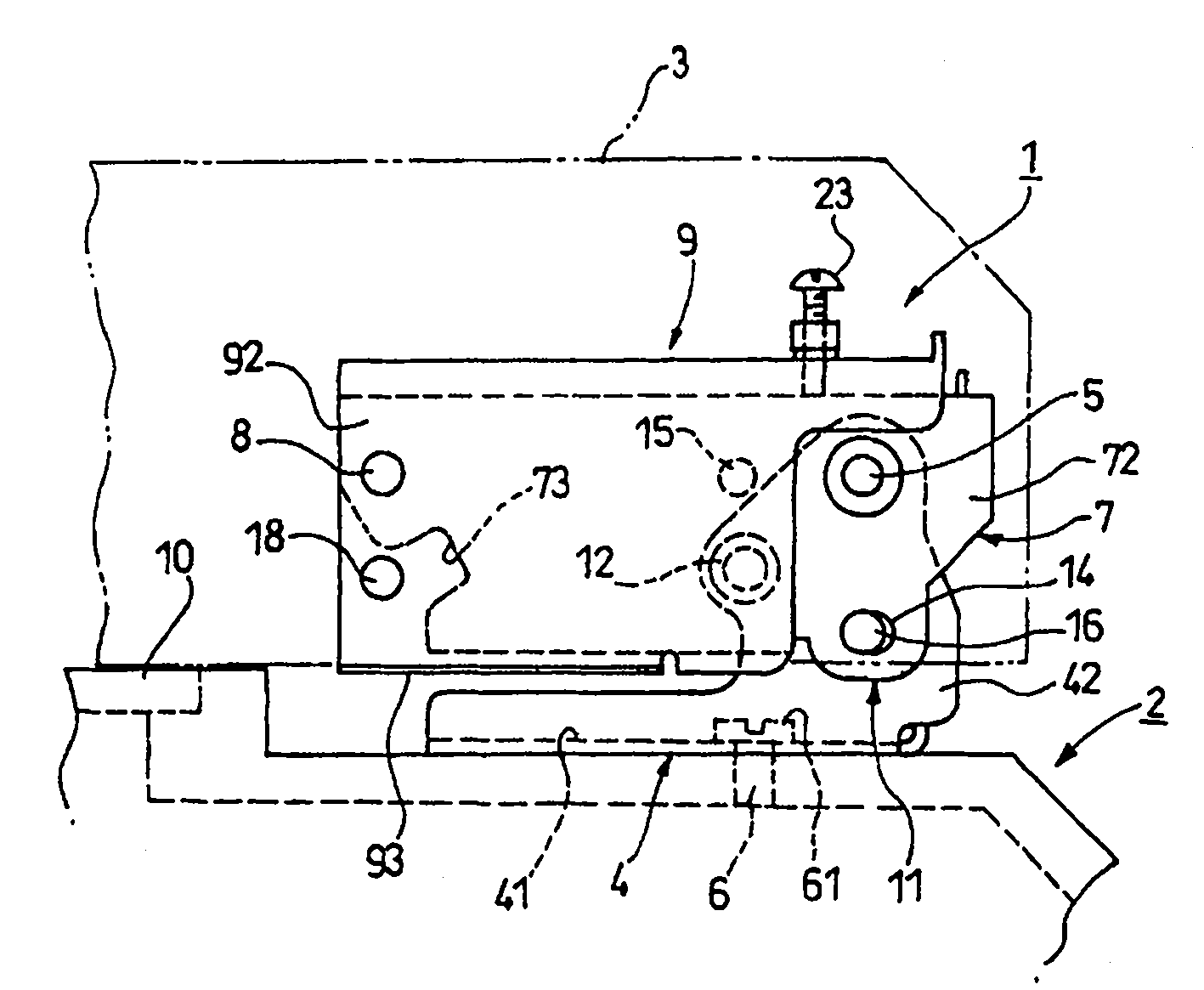

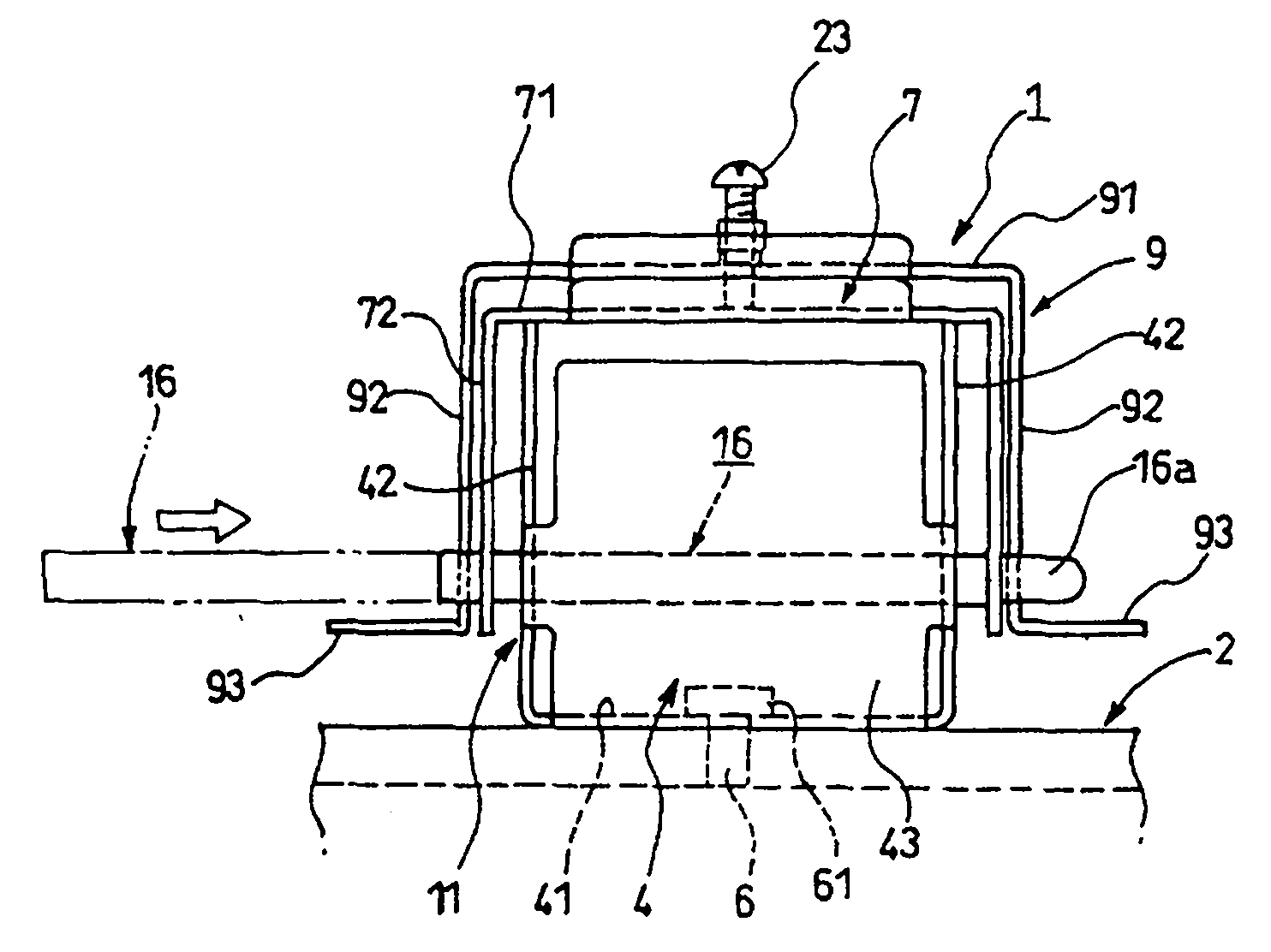

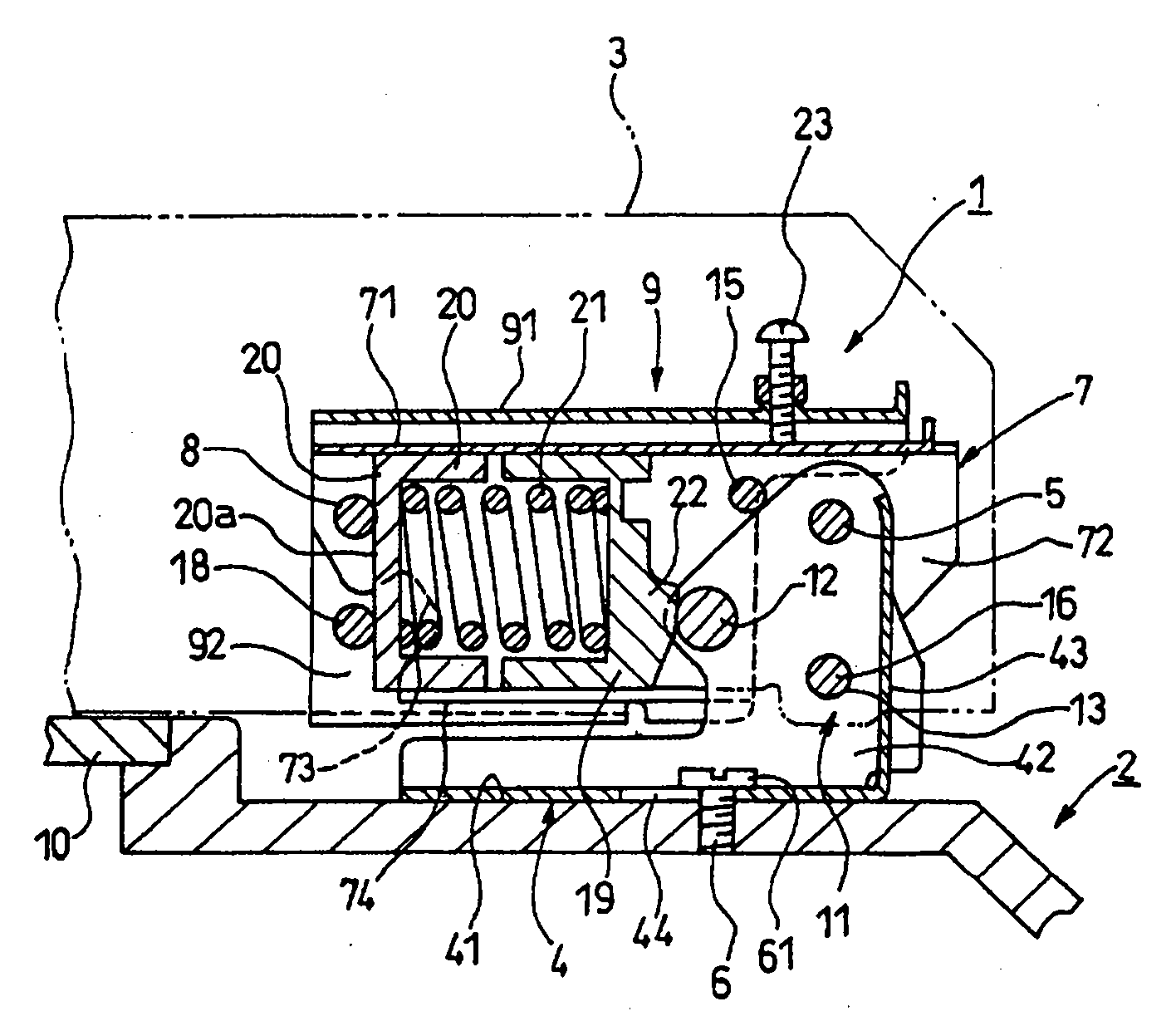

[0019] Next, the document pressure plate switching device of the present invention will be described in detail with reference to the accompanying drawings.

[0020] Figure 1 ~ Figure 3 It is an example of the document pressure plate switch device of the present invention. The original pressing plate switch device 1 of the present invention is a hinge mechanism installed on the device main body 2 of a copier, printing machine, facsimile machine, scanner, etc., which makes the original pressing plate 3 indicated by a phantom line face each other. The upper surface of the device main body 2 can be opened and closed. Such as Figure 1 ~ Figure 3 As shown, the original pressing plate switch device 1 of the present invention is composed of the following parts: the mounting part 4 is detachably installed on the rear upper end of the device main body 2 by installing the buckle part (taking and paying the buckle part material) 6; 7. It is rotatably connected to the mounting part 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com