Electromagnetic sound exchanger of flat vibration brushless motor

A vibrating motor, flat type technology, applied in the direction of sensors, electrical components, etc., can solve the problems of rotor magnet influence, trouble, etc., and achieve the effect of less leakage magnetic field and sufficient fixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

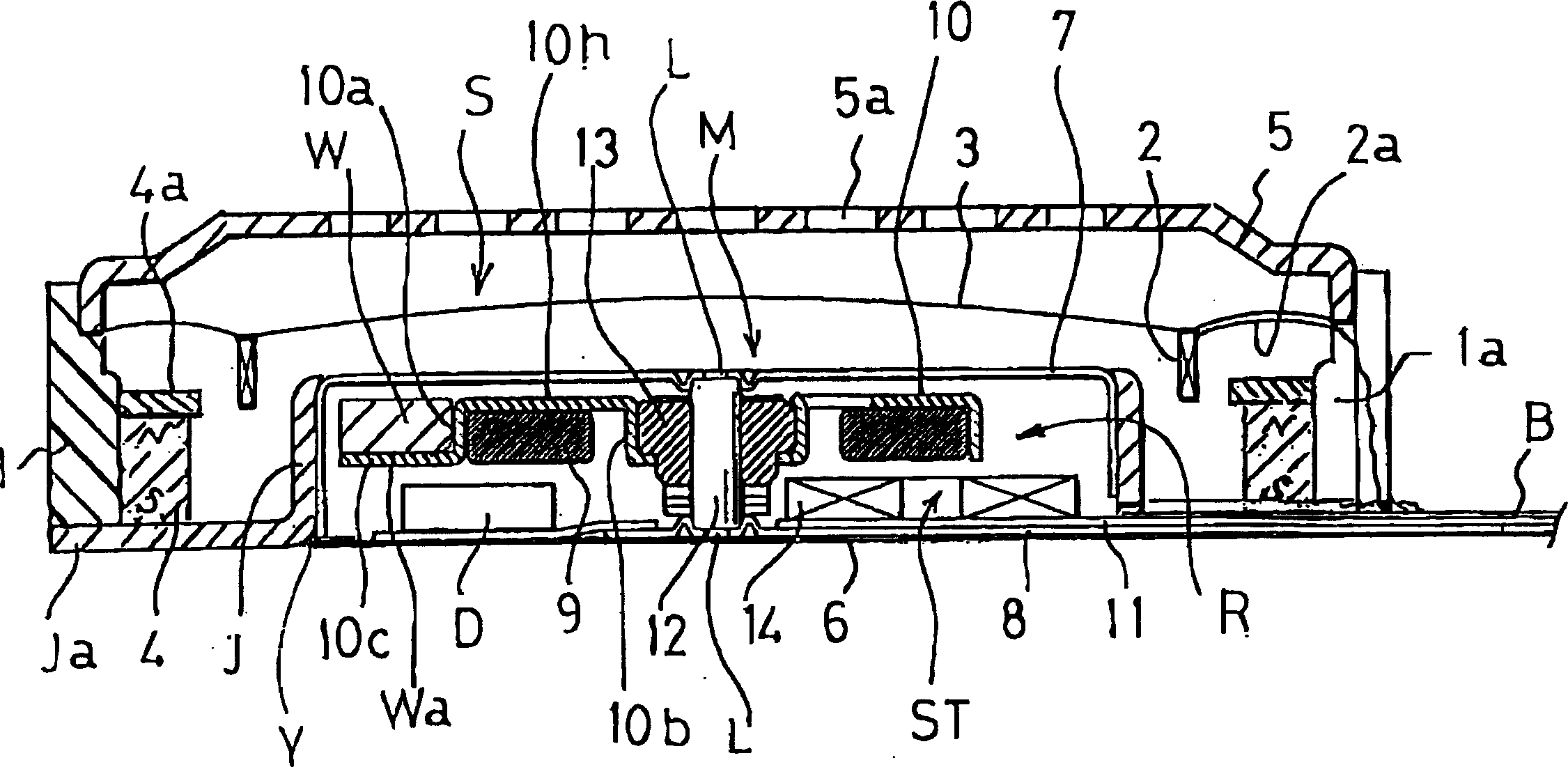

Embodiment 1

[0063] The electromagnetic acoustic transducer S of the present invention includes: a shallow cylindrical resin speaker case 1; a flat vibrating motor M arranged in the center and incorporating an eccentric rotor; An annular movable voice coil 2 in the shape of a multi-layer solenoid; a film-like vibrating plate 3 made of synthetic resin mounted on the above-mentioned casing with one end of the coil installed; The annular field magnet 4 that is assembled on the above-mentioned casing with the gap. The end 2a of the movable voice coil 2 is attached to the vibrating thin plate 3 by bonding or the like, and is led out to the power supply terminal part B through a partial gap 1a on the side surface of the speaker case 1 .

[0064] These components are covered with an inverted plate-shaped cover 5 attached to the above-mentioned resin-made speaker case 1 through the outer peripheral portion so as to press the outer periphery of the above-mentioned vibrating thin plate 3 . Here, th...

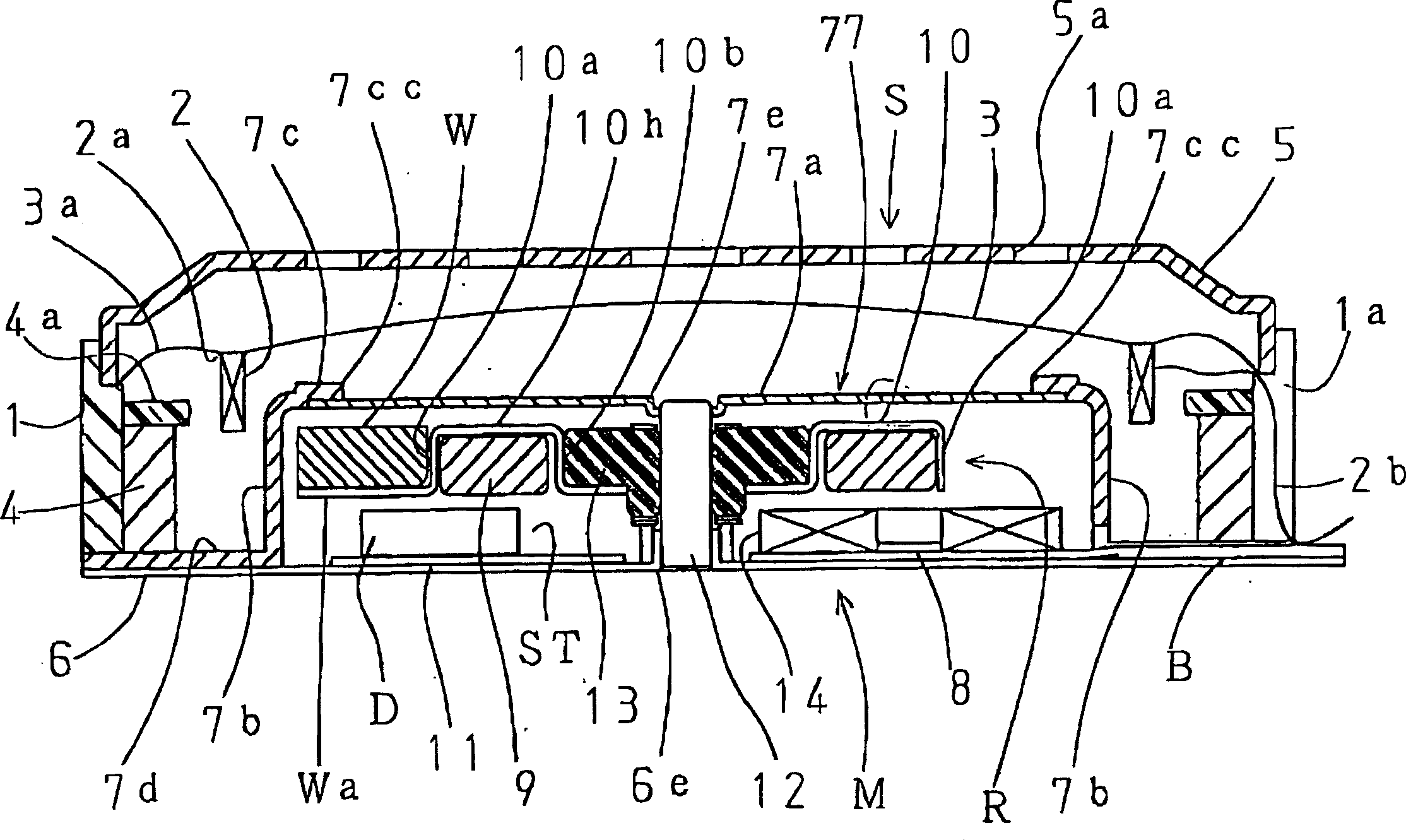

Embodiment 2

[0078] The structure of the electromagnetic acoustic transducer S is the same as that of the above-mentioned embodiment, and the same reference numerals are attached to the same parts including the brushless motor, and the description thereof is omitted.

[0079]The brushless vibration motor M is characterized in that the housing 77 is different from the above-described embodiments. The casing 77 is composed of a cylindrical portion 7b formed of a magnetic plate material, and a flange 7d formed continuously from the lower end of the cylindrical portion 7b, and the outer peripheral portion of the flange 7d is fixed to the lower end of the speaker case 1. side. The field magnet 4 is mounted on the speaker case 1 and the flange 7d.

[0080] The casing 77 not only forms a magnetic circuit for a speaker acting on the field magnet 4 , the yoke iron plate 4 a , and the movable voice coil 2 on the outer periphery, but also serves as a casing of the motor M. As shown in FIG. The flan...

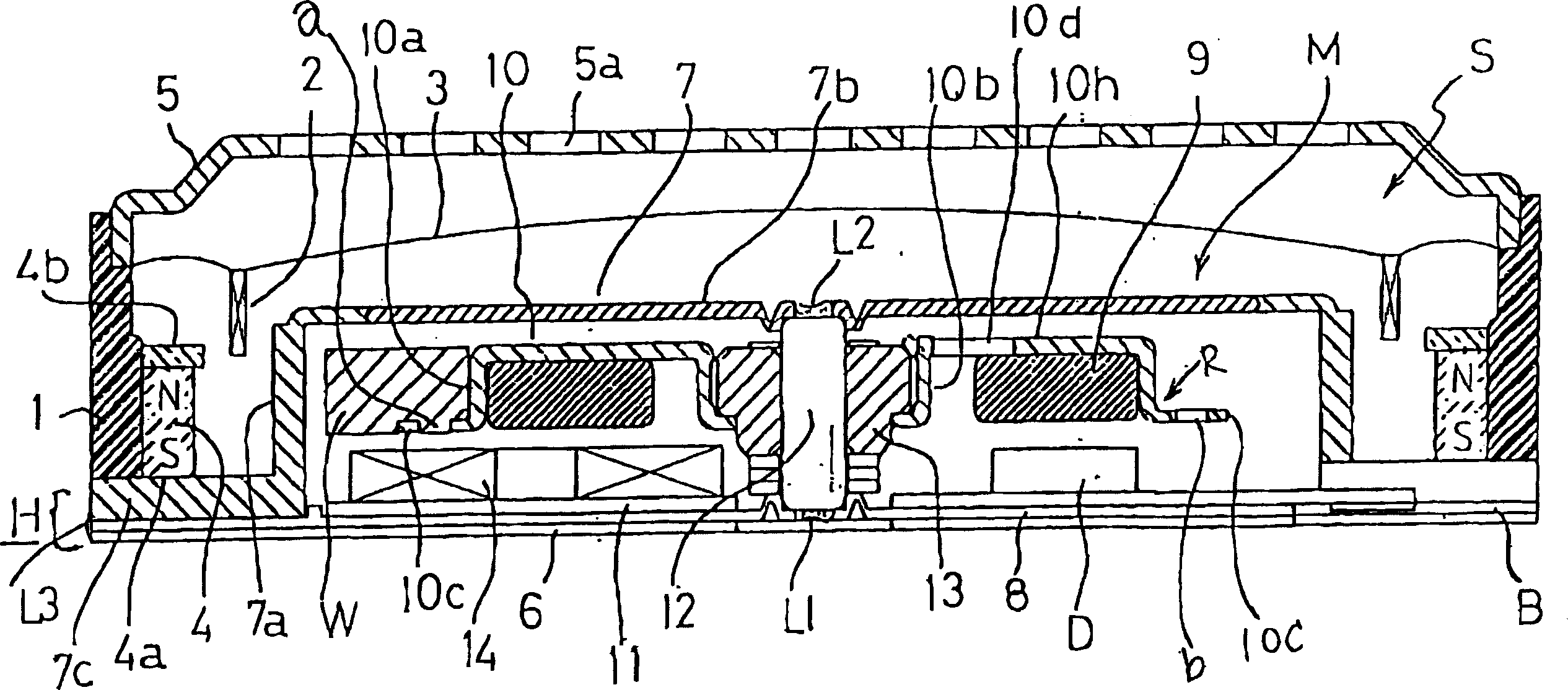

Embodiment 3

[0088] image 3 In the third embodiment, in order to obtain a magnetic field balance of the eccentric rotor, like the above-mentioned embodiments, the same reference numerals are attached to the same components, and the description thereof will be omitted.

[0089] The motor M constituting the present invention is constituted by a Hall sensor type single-phase brushless motor. As is well known, a single-phase brushless motor needs to stop the rotor at a predetermined position in order to start automatically, but if a magnetic body is directly used in the above-mentioned bracket 6 and housing 7, due to the magnetic force of a strong magnet, the starting Since it is difficult, it is necessary to ensure a large gap, but in order to make it thinner, it is generally necessary to make the bracket 6 a non-magnetic body except for the static torque generating member 8 . When the thickness is about 2mm, the rotor yoke 10 holding the magnet has to adopt a thin structure, and the leakag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com