Method of setting optimized pre-inking prior to the start of printing

A printing start and ink technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of incompatibility and insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

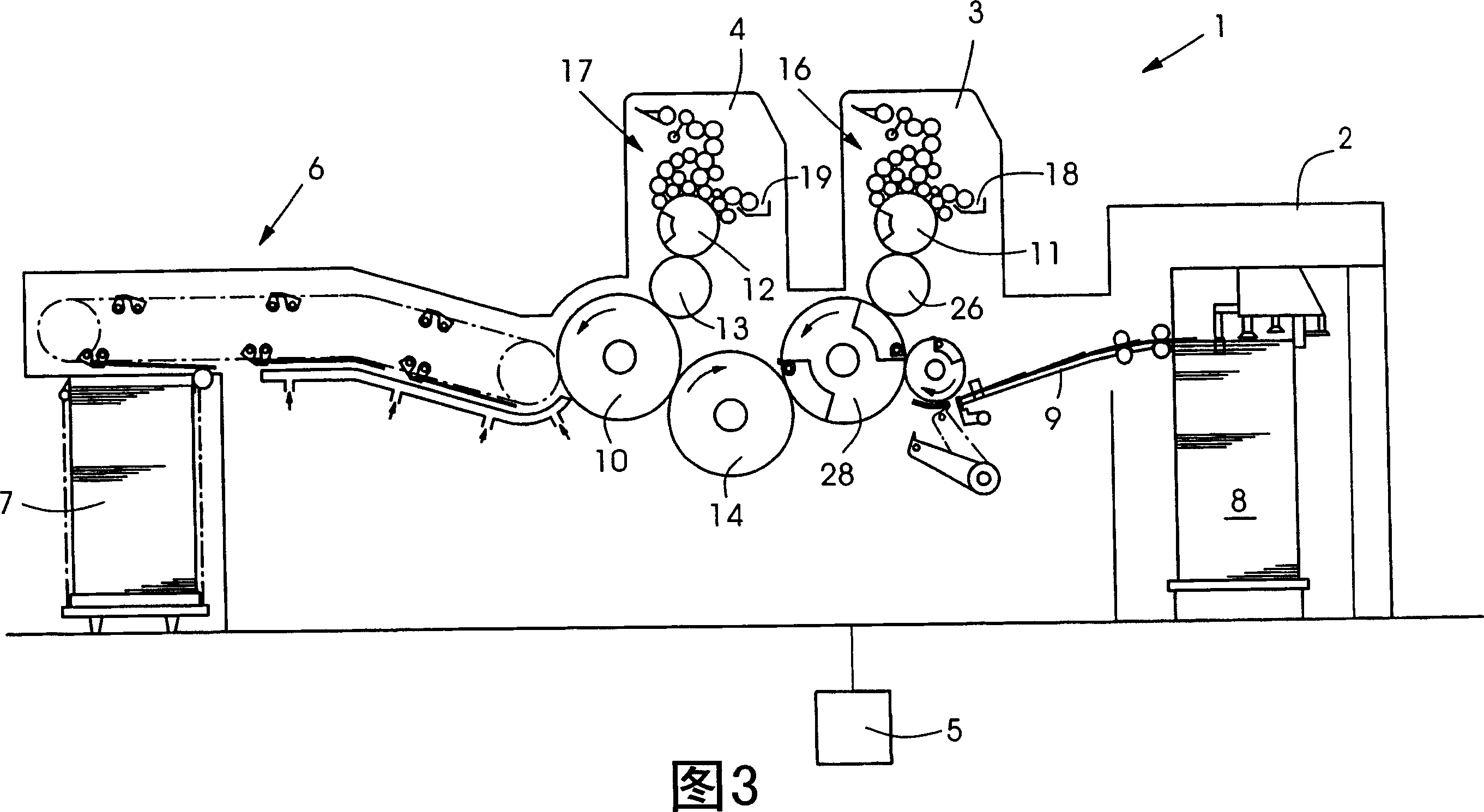

[0017] FIG. 3 shows a sheet-fed printing press 1 with two printing units 3 , 4 each having an inking unit 16 , 17 . In the direction of sheet travel, a feeder 2 is connected in front of the printing units 3, 4, which feeds the sheets from a feeder stack 8 to the first stage of the printing press 1 via a suction table 9. Printing device 3. The sheets are printed in the first printing unit 3 between a blanket cylinder 26 and an impression cylinder 28 by first color separations and are then transported via a transport cylinder 14 to the second printing unit 4 . In the second printing unit 4 , the sheet is then printed in a second color separation between an impression cylinder 10 and a blanket cylinder 13 . At the output of the second printing unit 4 , the printed sheets are transported via a delivery to a delivery stack 7 and can be transported to post-press processing.

[0018] In both printing units 3 , 4 , the printing ink is distributed uniformly over the entire printing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com