Refill for correction pen and refill unit

A technology of correction pen and correction fluid, which is applied to office supplies, printing, erasers, etc., and can solve the problems that the remaining amount of correction fluid cannot be correctly monitored, processing accuracy and assembly accuracy, difficult correction fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

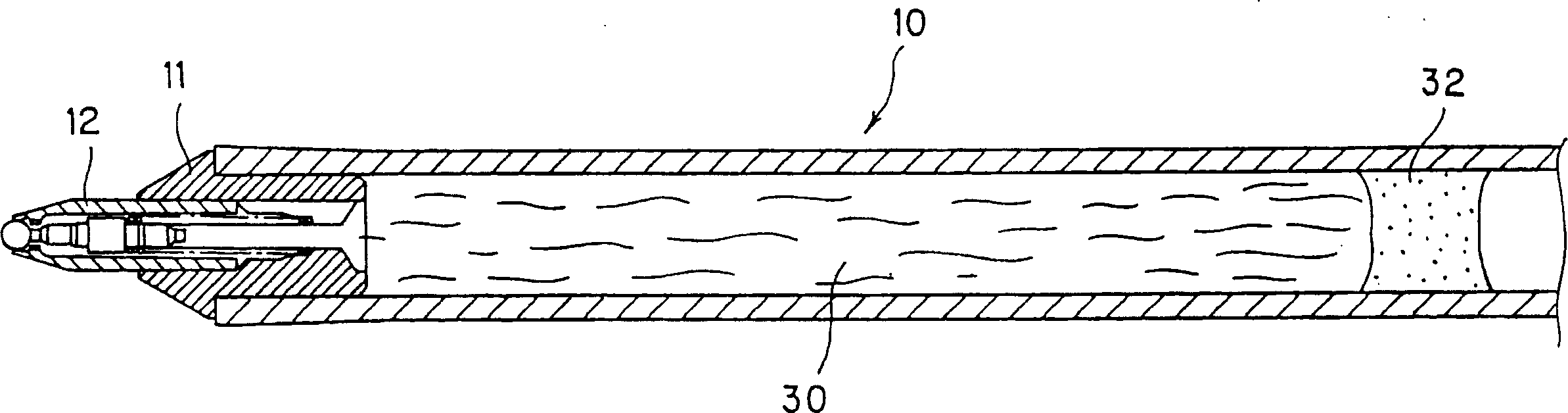

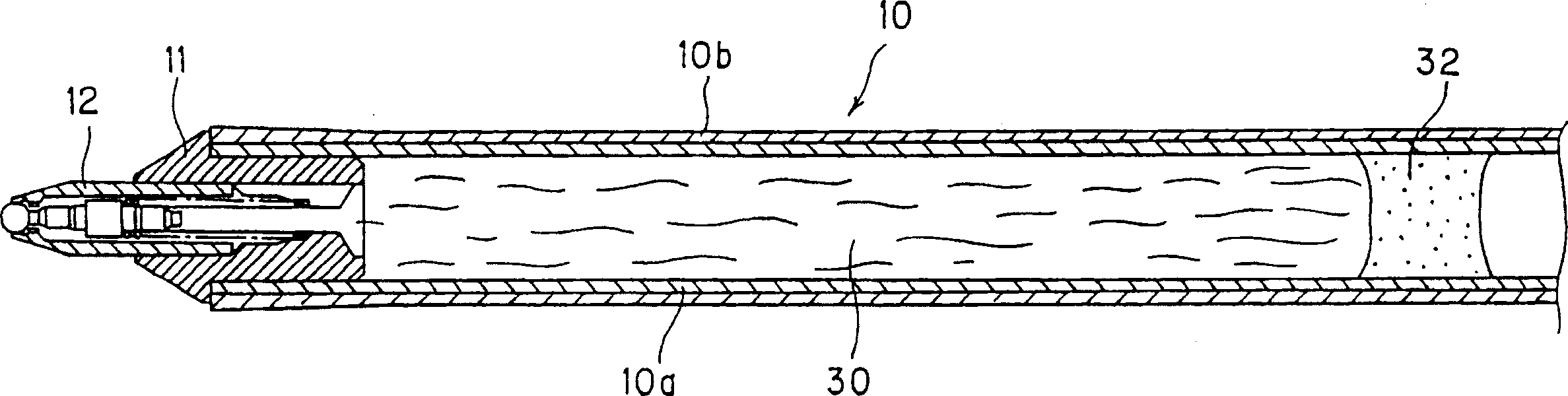

[0122] A tube with an outer diameter of 8 mm, an inner diameter of 6 mm, and a wall thickness of 1 mm was extruded from nylon MXD6 (manufactured by Mitsubishi Gas Chemical Co., Ltd., the same hereinafter) to form a 70 mm long refill for a correction pen.

example 2

[0124] A tube with an outer diameter of 8 mm, an inner diameter of 6 mm, and a wall thickness of 1 mm was extruded by a TROGAMID T5000 (manufactured by Daicel-Huels Co., Ltd.) to form a 70 mm long refill for a correction pen.

example 3

[0126]A tube with an outer diameter of 8 mm, an inner diameter of 6 mm, and a wall thickness of 1 mm was extruded from TROGAMID CX-7323 (manufactured by Daicel-Huels Co., Ltd.) to form a 70 mm long refill for a correction pen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com