Electromechanical trigger and an electronical safety appliance with the same

A trip device, electromagnetic technology, applied in electromagnetic protection switches, switches with electric heat and electromagnetic release, electrical components, etc., can solve problems such as reducing the reliability of relays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

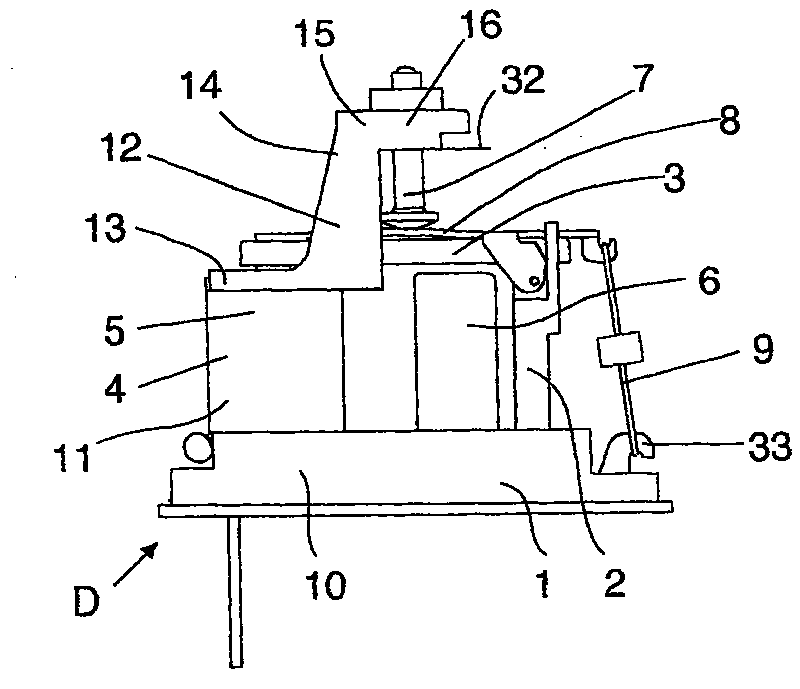

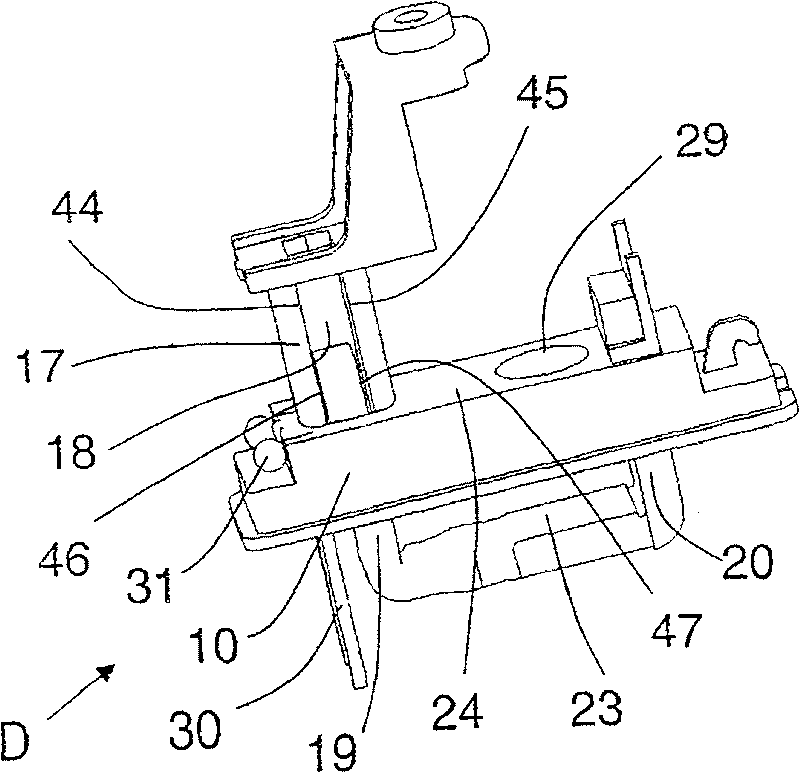

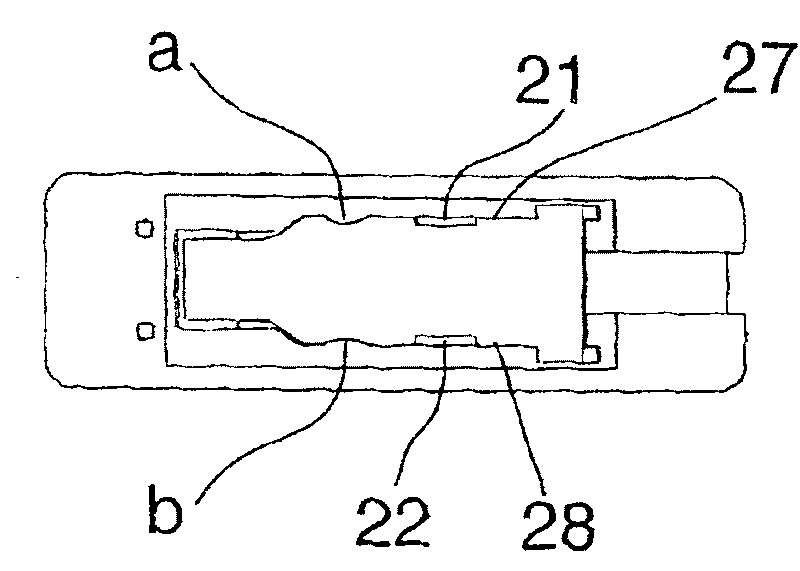

[0035] figure 1 , it can be seen that the electromagnetic tripping device D comprises, in a manner known per se, a bracket 1 supporting a U-shaped armature 2, the two ends of which form two polarized surfaces with respect to said armature 2 Pivoting vanes 3 co-operate, said vanes 3 being able to move over said polar surfaces to close the magnetic circuit formed by the armature 2 and the vanes 3 . This trip device D also comprises a trip coil 4 , mounted around a casing 5 surrounding the magnetic circuit, said coil being able to react against the force of the magnet 6 in order to move the vane 3 . This tripping device D also includes the reset pin 7 of the blade 3, which is used to act on the plate 8 fixed on the blade 3 and to damp the impact of the reset force. The function of the tripping device of the mechanism of the equipment; and the return spring 9 of the blade 3.

[0036] The operation of such a trip device D will be described later. At rest, with no current in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com